Supplier’s Marketplace

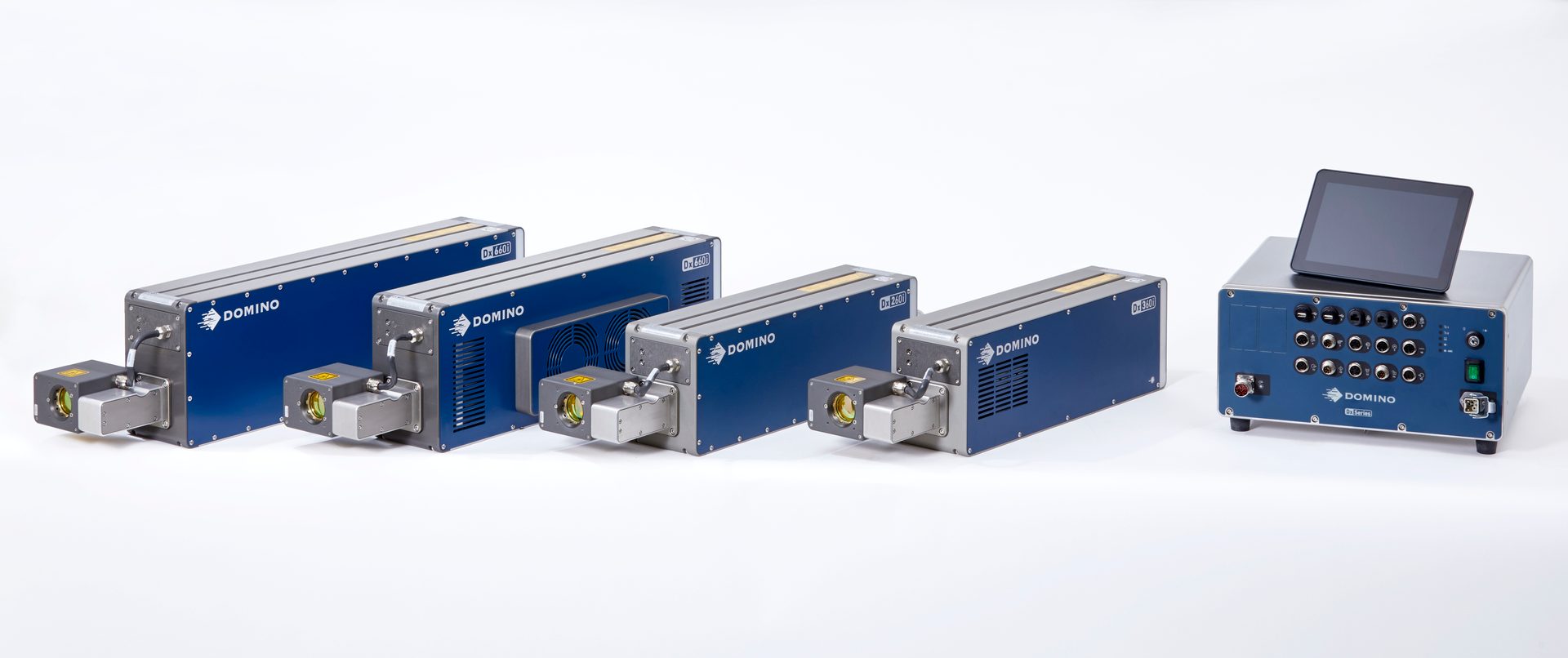

Domino Printing Sciences unveils new Dx-Series laser coders

The newly launched, next-generation CO2 laser coders from Domino Printing Sciences aim to help beverage manufacturers prepare for future high-resolution coding requirements, the company says. The Dx-Series laser delivers up to 30% faster coding than previous generation CO2 coders, it adds, with no reduction in code quality and an optimization for harsh environments typical of beverage applications. “The global laser market is expected to grow at a CAGR of 10% between 2023-2029; this growth can be attributed, at least in part, to increasing demand for high-definition on-pack 2D codes, including QR codes powered by GS1. This is driven by the GS1 Sunrise initiative to see 2D codes, including retail point of sales,” said Felix Rief, head of laser and extraction at Domino, in a statement. “These new code requirements are driving the need for reliable, high-resolution on-product printing solutions that won’t compromise production speeds.” Reliably printing 2D codes at high speeds can be challenging and cause manufacturers to slow down production line speeds, the company notes. However, the Dx-Series laser coders have been optimally designed to help beverage-makers meet these evolving code requirements with a new coding algorithm that facilitates up to 30% faster coding, with minimal stress on the substrate and no reduction to code quality, it says. “We are very pleased to be able to offer our Dx-Series laser coders to all global beverage brands,” said Tony McNulty, chief product officer at Domino, in a statement. “We recognize that the global transition to 2D codes will pose specific challenges for industries such as beverages, which require extremely robust, reliable and high-speed solutions. We are thrilled to be able to offer such a future-proof solution with our new Dx-Series, which is optimized for harsh environments, high speeds and code quality.”

Domino Printing Sciences North America

1290 Lakeside Drive, Gurnee, Ill. 60031; 800/444-4512; www.domino-printing.com

Aptar Closures targets reusable beverage containers market

Dispensing solutions provider Aptar Closures is targeting the growing reusable beverage containers market with its flow control valve and retaining ring combination system. The SureSnap is distinguished by contactless, leak-free dispensing, as it is a two-in-one pre-assembled valve and retaining ring. The product is “an attractive option” for reusable beverage container brand owners — including those offering water bottles, thermoses and children’s sip cups — seeking to differentiate themselves in an increasingly crowded market, the company says. A key advantage of SureSnap for reusable beverage container manufacturers is its snap and go assembly, the company notes. The preassembled valve and retaining ring system offer a fast, efficient assembly process with a simple mechanical snap-fit. This streamlines the assembly process for any reusable beverage container designed to be compatible with it. SureSnap eliminates the need for specialized equipment and expertise, unlike traditional three-piece assembly of silicone or rubber alternatives. Its small minimum order quantities and short lead times make it an ideal option for companies seeking smaller volume applications and speed to market, it says. “SureSnap addresses one of the more overlooked categories in the sustainability movement: reusability,” said Arthur Lenoir, director of global sales and marketing EFC for Aptar, in a statement. “As we advance toward a more circular economy, durable, high-performance solutions are essential. SureSnap’s functionality, hygiene benefits and durability make it ideal for the reusable beverage containers market, from water bottles and thermoses to children’s sip cups.”

Aptar Closures

265 Exchange Drive, Crystal Lake, Ill. 60014; 815/477-0424; www.aptar.com

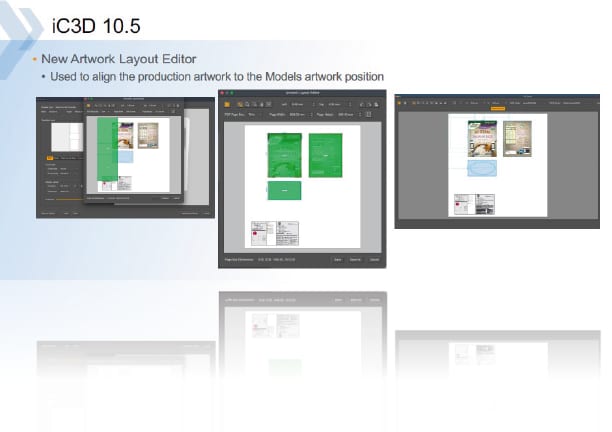

Hybrid Software’s BrandZ launches new 3D packaging mockup solution

BrandZ, a business unit of Belgium’s Hybrid Software, announced the launch of iC2D Suite 10.5, a real-time packaging mockup solution that enables designers, brand owners and manufacturers to innovate more effectively. The latest version reinforces iC3D’s leadership in providing cutting-edge design tools for packaging professionals, the company shares. iC3D Suite 10.5 introduced a powerful new Artwork Layout Editor for flexible bags, enabling designers to precisely modify panel layouts within bag templates to match production requirements, it adds. The intuitive editor allows users to set dimensions and align artwork across panels for perfect production layouts, streamlining the bag creation process while optimizing 3D Workflow Automation in CLOUDFLOW for seamless artwork replacement and consistency. “With iC3D Version 10.5, we’re reaffirming our commitment to providing packaging professionals with cutting-edge solutions,” said Heath Luetkens, sales director of Hybrid BrandZ America and business manager of 3D, in a statement. “These enhancements are designed to help users bring their creative visions to life faster and with greater precision than ever before.” The new solution was designed to reduce time-to-market and meet the evolving demands of the packaging industry, working as a game-changer for brand owners, converters and design professionals alike, the company says.

Hybrid Software USA

One South State St., Newtown, Penn. 18940; 215/550-6243; www.hybridsoftware.com

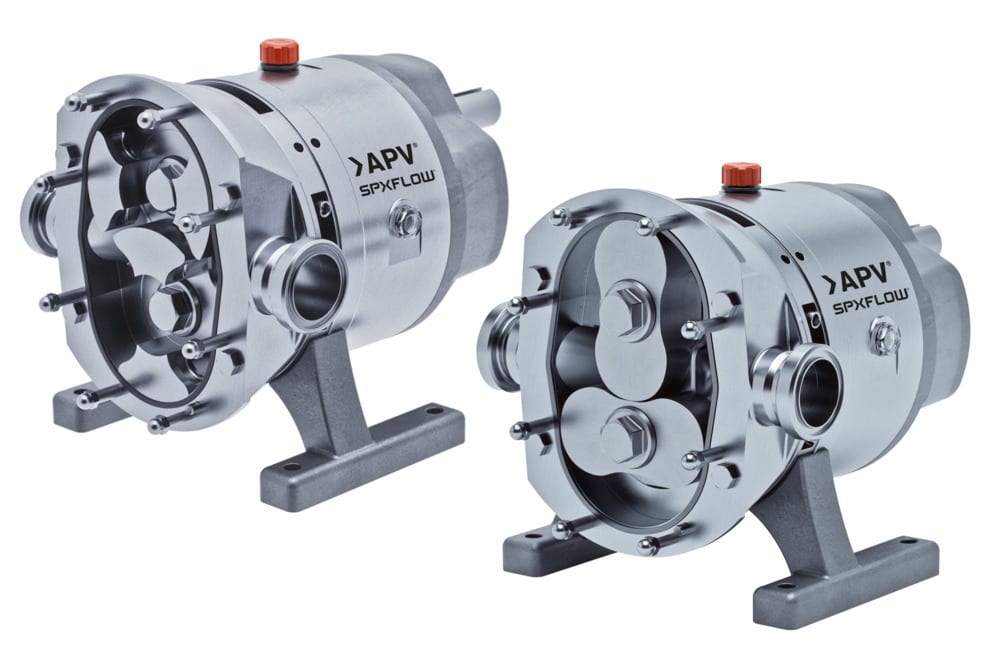

APV introduces positive displacement pump

SPX FLOW Inc.’s brand APV introduced the APV DW+ Positive Displacement Pump. The pump is the latest in its renowned DW Series and is engineered to optimize the processing of high-value, high viscosity products. The DW+ portfolio offers 27 different models and serves diverse industries, including food and beverage. The APV DW+ pump’s pulsation-free, low-shear design protects downstream equipment by minimizing vibration, noise and pressure, the company says. By doing so, it maximizes operational efficiency, reduces downtime and safeguards product integrity, it adds. The new pump offers pulsation-free operation, regulating flow with a unique piston rotor design. This reduces vibration, noise and pressure surges to protect downstream equipment and enhance operational stability. It also features versatile configuration, offering flexible processing with interchangeable piston or bi-lobe rotors for pumping various types of fluids, along with operational features, such as a rectangular inlet and thermal jacket, catering to specialized applications. The DW+ pump features an integrated pressure relief valve. This enhances safety by automatically releasing excess pressure, reducing the need for additional pressure-regulating devices and minimizing maintenance costs, APV says. Energy-efficient performance is another aspect, which reduces energy consumption through its minimal internal clearance design. This allows for the use of smaller, more efficient motors, leading to cost savings, the company notes. The new pump also offers gentle product handling. “We are proud to launch the latest innovation from APV, the DW+ pump, as the next generation of the trusted DW Series, which has delivered reliable performance worldwide for decades,” said Jet Liu, global product manager of nutrition and hygienic pumps, in a statement. “It is engineered to meet the evolving needs of modern processing operations. We are proud to introduce this proven and continuously evolving pump technology to the market so customers can experience its value and benefit from APV’s legacy of flexibility, quality and reliability.”

SPX FLOW

13320 Ballantyne Corporate Place, Charlotte, N.C. 28277; 704/752-4400; www.spxflow.com

BroadRange Logistics announced a $4 million incentive program for businesses with strategic warehousing needs. The company now will offer to build or acquire a warehouse tailored to a business’s operational requirements and help it grow without burden of ownership when expanding to any location in the United States, it says. “Our incentive plan is specifically designed for companies with a clear need for warehousing space,” said Ari Milstein, CEO, in a statement. “This program gives businesses of all sizes up to $4 million to invest in growth and operate within a warehouse managed by one of the fastest-growing logistics companies in the world.”

Zero-emissions transportation, energy supply and infrastructure solutions Nikola Corp. revealed that it and certain of its subsidiaries have filed voluntary petitions under Chapter 11 of the Bankruptcy Code in the United States Bankruptcy Court for the District of Delaware. The company enters Chapter 11 with approximately $47 million in cash on hand to fund foregoing activities, implement the post-petition sale process and exit Chapter 11 through a plan process. “In recent months, we have taken numerous actions to raise capital, reduce our liabilities, clean up our balance sheet and preserve cash to sustain our operations,” said Steve Girsky, president and CEO, in a statement. “Unfortunately, our very best efforts have not been enough to overcome these significant challenges, and the board has determined that Chapter 11 represents the best possible path forward under the circumstances for the company and its stakeholders.”

JBT Marel Avure Technologies announced its findings on the effects of high-pressure processing (HPP) on nutritional components in fruit, vegetables and herbs compared to thermal treatment. HPP inactivates harmful pathogens by processing foods at extremely high water pressure, giving consumers safer packaged fruit and vegetable products with fresh, just-prepared characteristics without additives or preservatives, the company shares. HPP is applied in the product’s final packaging, eliminating the risk of contamination and protecting producers and consumers from recalls. Avure Technologies, working with clients around the world, concluded that HPP did not affect the antioxidant and anti-inflammatory bioactive compounds in juices at different HPP treatment conditions.

Manufacturer of commercial ice and refrigeration equipment Hoshizaki America announced the promotion of Omar Marrero to regional sales director for the Southeast region. Marrero has two decades of dedicated service at the company, with a proven track record of leadership. “Omar’s extensive industry knowledge, leadership experience and dedication to our customers make him the perfect choice to lead the Southeast sales team,” said Scott Meyer, vice president of regional sales at Hoshizaki America, in a statement. “We are excited for the future of the region under his direction.”