Supplier's

Marketplace

Videojet Technologies Inc.

1500 Mittel Blvd., Wood Dale, Ill., 60191; 800/843-3610; videojet.com.

Videojet Lightfoot fiber laser solution

Videojet Technologies Inc. introduced a new Lightfoot canning solution, which combines the standard reliability of a Videojet fiber laser with the speed of dual Lightfoot marking heads to meet the demanding production needs of beverage canning manufacturers. Purpose-built for the beverage industry, the Lightfoot canning solution is designed with robust components including IP69 rated marking heads and an IP65 rated supply cabinet that can handle humid, sugar-laden or washdown environments. Featuring dual Lightfoot marking heads seamlessly integrated with one software control, the Videojet canning solution is able to reach marking speeds as fast as 100,000 cans an hour, the company says. The all-in-one canning solution includes a Class 1 sealed enclosure to help ensure that operators are safe from any optical radiation, while an integrated fume extractor protects workers from harmful aluminum dust and fumes. Designed for easy integration, a modular beam shield fits around conveyor belts. Meanwhile, the marking head air knife keeps the beam exit window clean of dust and dirt build-up. The comprehensive package includes VideojetConnect Remote Service and ongoing, free support on using fiber laser technology.

EMSURE ECOEM-Sleeves

EMSUR presents a new range of shrink sleeves, ECOEM-Sleeves, which are fully recyclable along with PET bottles. The new sleeve solutions are based on a combination of films and washable inks that aim to improve the recycling process and avoid contamination from material residues, the company says. Made at its Technology Innovation Centre INNOTECH, ECOEM-Sleeves provide a new range of sustainable shrink sleeve solutions for bottled carbonated drinks, water, juice or drinkable yogurts. Among the advantages of bottle sleeves are easier recycling, product differentiation on shelves and the ability to display strategic brand messages or nutrition information on the product's contents. Although traditional bottle sleeves should be removed from bottles at the washing stage to avoid contamination of the PET flakes prior to recycling, the ECOEM-Sleeves utilize a combination of films and washable inks to simplify the recycling process. Among the different types of sustainable sleeves offered are the ECOEM-FULL PET Sleeve and the EMFULL, a polyolefin-based sleeve option whose floatability properties allow the sleeve to be directly separated from the bottle during the washing phase of the recycling process. This product range also features the PETG, which is available in different types of finishes such as high gloss or matte, transparent and other differentiating elements such as holographic effects, glow-in-the-dark pigments, and gold and silver inks.

EMSUR

Avda. de Madrid, 72 - 28802 Alcalá de Henares, Madrid; +011/34-918-775-900; www.emsur.com.

Bevi

529 Main St., Suite 304, Charlestown, Mass. 02129; 617/315-4715; www.bevi.co.

Bevi’s Standup 2.0 enhanced water machine

Beverage technology company Bevi launched its new smart water cooler, the Standup 2.0. Designed for commercial locations, the enhanced water machine allows for mixing flavors, adding enhancements like caffeine, hot water and more. The new water dispenses allows users to customize filtered and sparkling water in seconds by setting temperature, carbonation level, and combinations of natural flavors and enhancements, the company says. The Standup. 2.0 elevates the water cooler experience through an ergonomic design, the addition of enhancements such as vitamins and electrolytes, the ability to customize water temperature and carbonation level, a new interface for quickly mixing and matching ingredients, and advanced remote diagnostics to keep machines in top condition, it says.

Spencer Strainer self-cleaning filters

Spencer Strainer offers sanitary self-cleaning filters for process flows of as much as 400 gallons per minute (gpm). Constructed of 316-L stainless steel, the food grade strainers work continuously in a sealed environment. Because there are no bags or elements to replace, no inherent downtime for filter changes is required, making the strainers an environmentally friendly option to help beverage plants meet their sustainability goals, it says. In addition, wedgewire or perforated screens of various openings are available and interchangeable, allowing one strainer to be used for multiple food processing applications including orange juice, alcohol and dairy products. The strainers are suitable for aseptic operation and work well as pre-filters upstream of membranes, centrifuges and other fine filter media. Food grade models are available for process flows of 100 gpm and 400 gpm and rated up to 180 psi and up to 400 psi, respectively. Spencer strainers are suitable for aseptic operations and work well as pre-filters upstream of membranes, centrifuges and other fine filter media.

Spencer Strainer

6205 Gheens Mill Road, Jeffersonville, Ind. 47130; 812/282-6300; www.spencerstrainer.com.

Agr Process Pilot automated blowmolder control system

Agr International Inc. offers its Agr Process Pilot automated blowmolder control system to provide an extra layer of process management and quality assurance for a German juice maker shifting from 25% recycled PET (rPET) to 100% rPET bottles in response to a sustainability directive. The Process Pilot provided a “technical safeguard” to ensure that the blowmolding production process is stable and robust. Noting that stability in environmental conditions and in materials is always a big concern in blowmolding, even more so due to irregularities inherent in rPET as an amalgam of plastics from different sources, the company explains that the more recycled resin there is in a preform, the harder it is for the blowmolder to achieve the material distribution targets required for well-performing bottles. The variability in rPET results in non-conforming bottles and creates downstream problems like jams in the labeler due to skewing. The granular control of the Process Pilot system, powered by sophisticated algorithms, counteracts all these variables, automatically triggering corresponding changes in process settings to adjust for irregularities. The Process Pilot, working inside a KHS Series IV reheat stretch blowmolder, is producing roughly 30,000 100% rPET containers an hour. Any non-conforming bottles are diverted from filling, avoiding product waste and preventing them from getting to market.

Agr International Inc.

615 Whitestown Road, Meridian, Pa. 16001; 724/482-2163; www.agrint.com.

Michelle Bryson was named global sustainable packaging leader for St. Louis-based BW Packaging Systems, the packaging equipment arm of Barry-Wehmiller. Bryson will lead the development of a sustainability roadmap for the company, and collaborate with team members and customers on several fronts, including the usage of responsible materials, recyclability, packaging design, waste, carbon footprint reduction and more. She also will work to ensure that all future packaging solutions are developed with due consideration of local legislation, recycling streams, carbon emissions and other environmental priorities, the company says.

Entries now are open for the Colored By INX Can Design Contest. Sponsored by Schaumburg, Ill.-based INX International Ink Co., the contest is open to all brand owners, design agencies, marketers and metal decorators who produced a commercial can design before Dec. 31, 2021, while using the INX Color Catalog. Entries for this year’s contest must be postmarked by April 29, and a new approach is being applied to determine the finalists and ultimately the winner. Crown Brand Building Packaging won the first title in 2020 with its entry of INDIO Beer’s Pueblos de México Unido Edición Muertos. Great Lakes Brewing Co. in Cleveland took the top honors last year for its Crushworthy Lo-Cal Citrus Wheat beer can design. An independent panel of six judges will review and make the selections during the voting process.

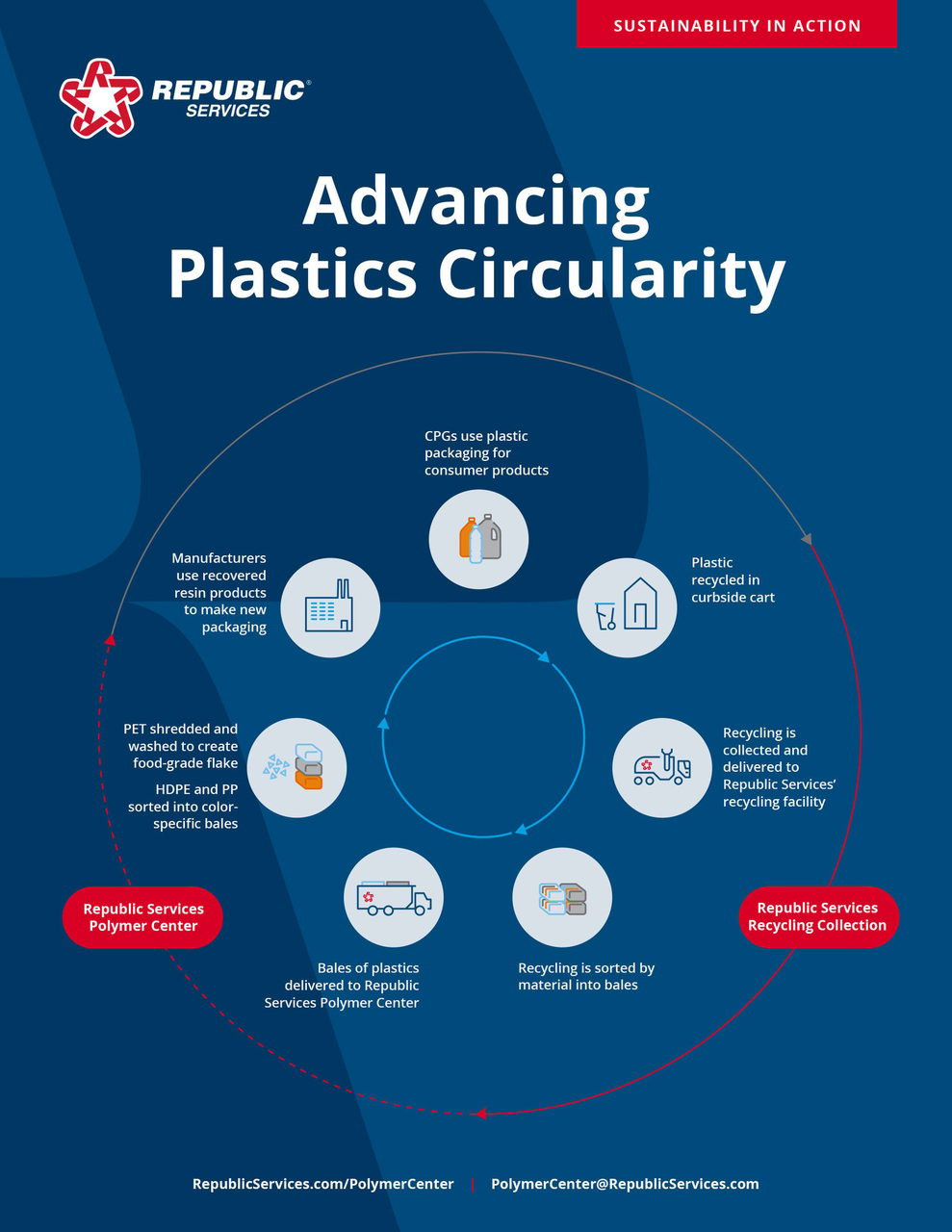

Republic Services, Phoenix, announced plans for an integrated plastics recycling facility, designed to address the increasing demand from consumer brands and packaging manufacturers for recycled plastic. The Republic Services Polymer Center represents the first time a U.S. company will manage the plastics stream through an integrated process from curbside collection of recycled material to production and delivery of high-quality recycled content for consumer packaging, it says. Set to open in 2023, the Las Vegas facility will produce more than 100 million pounds a year of recycled plastic products, including 100% post-consumer PET flake delivered to the food-grade marketplace to enable bottle-to-bottle circularity. In addition, HDPE and PP packaging, such as detergent jugs, which today are collected in multicolored bundles, can be separated by color, allowing, for example, an orange jug to be recycled into another orange jug. The new facility will help brands meet their voluntary sustainability pledges and remain compliant with new California and Washington regulation stipulating greater use of recycled plastic, it says.

Londonderry, N.H.-based Admix Inc. appointed Tim Dining as its new chief operating officer (COO). With more than 30 years of experience leading manufacturing operations environments, Dining will utilize his strengths in implementing manufacturing technologies and improving workflow processes to grow the company’s product lines and implement lean principles while maintaining the employee-owned culture centered on teamwork and customer focus.

Universal Compressed Air (UCA), Bethlehem, Pa., will install a Compressed Air System at John Deere’s foundry in Waterloo, Iowa. UCA will provide compressed dry air to John Deere under its long-term Pipeline Air performance contracting model. A Pipeline Air contract combines UCA’s compressed air supply expertise with the capabilities of highly efficient centrifugal air compressors, air dryers, cooling systems and master control system. UCA will execute the design, construction, commissioning, startup, maintenance and operations of the new state-of-the-art plant.

JW Winco, New Berlin, Wis., updated its new Standard Parts Handbook, which is designed to support mechanical engineers, designers, drafters and innovators for machine and equipment builders with more than 75,000 standard parts including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components. The 2,184-page handbook can be ordered free of charge by emailing sales@jwwinco.com.