Supplier's

Marketplace

Standalone fueling system from Propane Fueling Solutions

Propane Fueling Solutions revealed its latest infrastructure: a standalone fueling system. The systems allow fleets to refuel with propane or recharge with DC level 3 fast chargers independent of the grid. It combines a 60kW propane generator with wind and solar power, creating a microgrid and allowing fleets to implement a drop-in charging solution in an efficient manner, the company notes. The skid infrastructure also features a refueling station for propane autogas vehicles, it adds. “We’ve seen it time and time again — the grid fails, the wind doesn’t blow, the sun doesn’t shine and an electric vehicle fleet is grounded because it can’t recharge,” said Mauricio Morafiallos, CEO of Propane Fueling Solutions, in a statement. “Propane can be there in those moments to provide a clean, reliable power solution. Historically, EV fleets have relied on diesel generators for a portable charging solution. In those cases, all the good you’re doing with EVs is going out the window when those diesel emissions are released. Propane eliminates that issue.” The skid solution is significantly less expensive compared with traditional EV charging infrastructure, the company says, and it cuts costs as much as 75% or more.

Propane Fueling Solutions

1700 Post Oak Boulevard 2 Boulevard Place No. 600, Houston, Texas 77056; 830/424-3703; www.propanefuelingsolutions.com

Slam-Shut valve from Emerson certified for use in hydrogen applications

Emerson’s BM6X Series Slam-Shut valve was approved by Bureau Veritas Italia for uses up to 100% hydrogen and pressures up to 100 bar. The commitment of Emerson and Bureau Veritas enabled this certification, which ensures the availability of suitable products in new hydrogen infrastructure, the company says. With this certification, the material suitability is confirmed based on internal and external seal tests performed at Emerson’s Italian production plant, it notes. In a statement, standardization and product engineer with Emerson’s pressure management research and development team, Oscar Bressan said that Emerson, along with Bureau Veritas Italia, has developed procedures to assess the suitability of products to be used in gas infrastructure applications. “The Emerson procedures describe the requirements, tests, and inspection methods for metallic and non-metallic materials, as well as internal and external sealing necessary to use pressure control products in contact with natural gas and blended hydrogen, or pure hydrogen,” Bressan said. “After the first certification obtained for the Emerson BM6X Series Slam-Shut valve, Emerson will continue to certify other equipment used in hydrogen infrastructure to ensure sustainability and reliability for this rapidly developing market.”

Emerson

8000 West Florissant Avenue, P.O. Box 4100, St. Louis, Mo. 63136; 314/553-2000; www.emerson.com

Medium viscosity and shear mixer latest from ROSS

A multi-shaft mixer customized for low to medium viscosity is the latest from Charles Ross & Son Co. The ROSS Model CDA-200 is specially made, with a two-wing anchor agitator and two medium-speed agitators. The agitators are each fit with five rows of three-blade pitched turbines. With two portable stainless steel mixing vessels and transport covers, the mixer is designed for continuous operation. It also features a 4-gallon charging hopper to introduce ingredients to batches and a thermoprobe, ensuring accurate readings of temperatures. The company says all three agitators “are driven independently by explosion-proof inverter-duty motors.” Teflon scrapers are included in the two-wing anchor, and the scrapers contact both the jacketed sidewall and bottom surfaces, it notes. Vacuum operation up to 29.5-inch Hg is enabled with the Double FlexiLip seals and silicone O-rings — ideal for creating air-free pastes, slurries, gels and suspensions, it says. ROSS’ line of Multi Shaft Mixers are designed for heavy-duty use, offering protection against contamination.

Charles Ross & Son Co.

710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-ROSS; www.mixers.com

Refrigeration unit from Carrier Transicold boasts reduced emissions, fuel savings

The latest trailer refrigeration unit from Carrier Transicold, the X4 7700, boasts high refrigeration capacities, reduced emissions and demonstrated fuel savings, it says. With an advanced version of the smart engine used in Carrier Transicold’s existing trailer platforms, the unit features enhanced compliance with the California Air Resources Board’s (CARB) rules for trailer refrigeration systems, the company notes. A better fuel economy is achieved with “eco speed,” which reduces the engine’s RPMs when permitted, as well as common-rail fuel injection, it says. These enhancements demonstrated average fuel savings of 20 to 25%, it adds. “In full production at our world-class manufacturing facility in Athens, Georgia, the new premium performance X4 7700 single-temperature unit builds on the X4 platform’s decade-long reputation for high capacity and rugged, dependable service,” said Bill Maddox, senior manager of product management, Truck Trailer Americas, Carrier Transicold, in a statement. “Continuing the tradition of reliable design and simply smarter engineering, the X4 7700 unit offers a 96% reduction in particulate emissions and double-digit gains in fuel efficiency compared to standard X4 models.” The unit also boasts lighter weight, at 1,690 pounds, and the highest capacity compared with its predecessor in the X4 Series, the company notes.

Carrier Transicold

13995 Pasteur Boulevard, Palm Beach Gardens, Fla. 33418; 561/365-2000; www.carrier.com

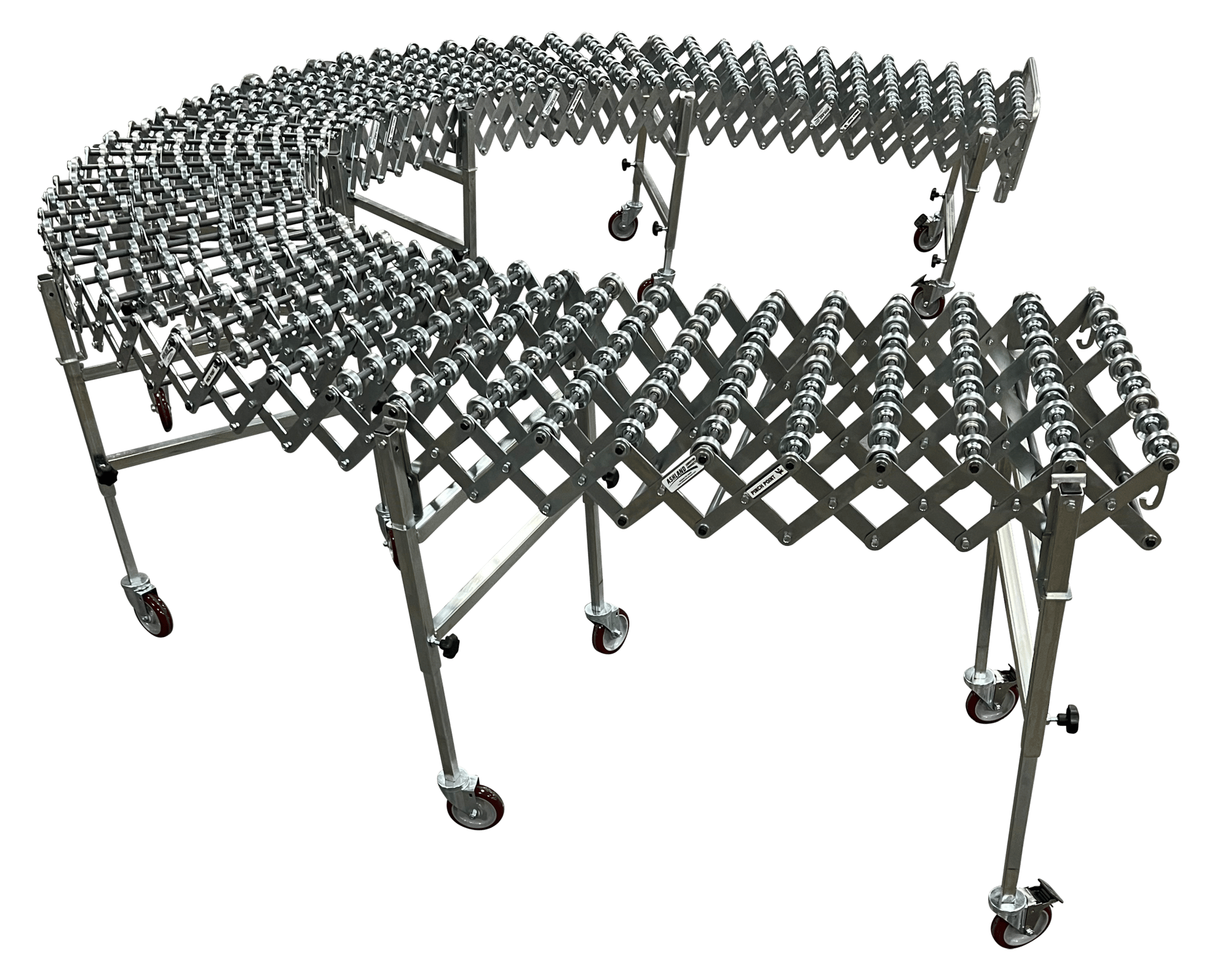

ProVeyance shows off new FlexExtend Conveyor System

ProVeyance Group unveiled its new FlexExtend Conveyor System at PROMAT 2023. PROMAT took place at McCormick Place in Chicago from March 20 to 23. A flexible gravity conveying system, the FlexExtend features self-tracking skate wheels and is designed for low- to medium-volume conveyance operations of multiple sizes. “FlexExtend is fully customizable to meet our customer’s conveyance needs and will include options for conveyor rollers and dock accessories for maximum efficiency,” Tim Swineford, president of Ashland Conveyor, a ProVeyance company, said in a statement. The company says the high-flow products can be extended, contracted or flexed into curves to meet material handling requirements. “Our company is backed by more than 100 years of conveying industry expertise through our Woodsage and Ashland legacy companies,” said Tim Carpenter, ProVeyance president and CEO, in a statement. “With our focus on innovation, quality and customer experience, we provide exceptional value to many different industries through our full suite of conveying components and equipment supply.”

ProVeyance Group

7400 Airport Highway, Holland, Ohio 43528; 419/866-8000

Technology-driven ingredients provider ingredients PLUS recently received the British Retail Consortium (BRC) certificate for its Landisville, Pa.-based plant. The company says the certificate is a food safety stamp of approval for the plant, which opened in 2022. “BRC’s rigorous audit and certification underscores our commitment to product safety in the supply chain,” Doug Wagner, president and CEO of ingredients PLUS, said in a statement. Trever Wetzel, Landisville plant manager, added: “With our state-of-the-art, agile and automated operations, we can swiftly and efficiently service customers with quality ingredients they depend on.”

Danfloss Climate Solutions recently finalized its acquisition of BOCK GmbH, a world leader in carbon dioxide and low-GWP compressors. BOCK’s 90 years of compressor innovation is now united with Danfoss’ decades as a full-solution leader, as the acquisition became official in the beginning of March. “This is a proud moment in BOCK’s history, as we look to continue our growth journey as part of the Danfoss family,” said Dr. Marcus Albrecht, BOCK’s CEO, in a statement. “Danfoss’ global presence will open new business opportunities for BOCK, and together, we have high hopes for the future. Innovation will continue to be central to our work, as we look to elevate more sustainable cooling and heating worldwide.”

E-Volve Systems was obtained by E Tech Group as of late. E-Volve is a provider of systems to clients in the food and beverage industries, among others. The company now will operate under the name “E-Volve Systems, an E Tech Group Company.” In a statement, E Tech’s CEO, Matt Wise, said that the company is thrilled to add E-Volve to the group. “Their deep footprint in life sciences combined with our extensive client set makes us a clear leader in the space,” he stated. “Additionally, our combined clients and services enables E Tech to offer one of the automation industry’s broadest services sets, from cyber security and OT optimization, through automation design, systems integration, industrial data management and business intelligence with 24/7 support. We fulfill the promise of a one-stop shop for advanced automation.”

A monthly share in digital can printers NOMOQ recently was acquired by Ardagh Metal Packaging (AMP). AMP says this gain extends its support of newcomers in the beverage market. NOMOQ is a Switzerland-based startup, promising “beautifully printed cans with short lead times and ‘NO Minimum Order Quantity,’ hence the name.” In a statement, Oliver Graham, CEO of AMP, called the acquisition a perfect fit. “NOMOQ’s offer is innovative, customer-centric, and extraordinarily flexible — areas in which AMP has established a great reputation,” Graham stated. “Their dedication to creating outstanding packaging for customers of all sizes will enhance our ability to serve early-growth customers in the European market and extend our offering to established customers too.”

Mott Corporation announced it will open a 65,000 square-foot facility near its headquarters in Farmington, Conn. It will house at least 100 new employees, doubling as the company’s production capacity for its custom-designed engineering solutions. “Mott has pioneered unique technology that the world’s leading energy producers need to generate green hydrogen, and the new facility will dramatically expand our production capacity,” said CEO Boris Levin in a statement. “We’re able to do that in part because, as an employee-owned company, we’re able to recruit the best talent — and give our employees a share in our success. I’m very grateful to Governor Lamont, Senator Blumenthal and all of our elected officials for advocating for cutting-edge companies like ours that are growing and creating jobs in Connecticut.”

April 2023 | bevindustry.com