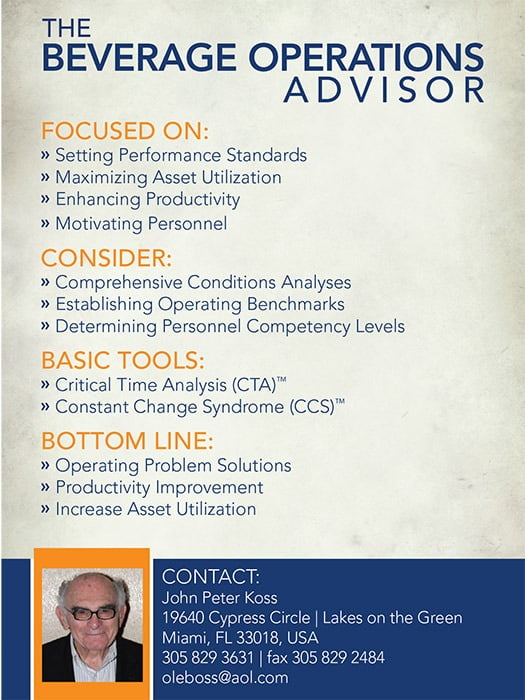

Supplier's

Marketplace

New Multi-Conveyor Canning Line Layout

Multi-Conveyor in collaboration with sales partner Purvis Industries announced the modification of the layout of its high-speed canning line by adding intermediate sections and incorporating a massive stainless steel bi-directional accumulation table. The modification includes a 51-foot mass flow transport conveyor section and a 54-foot-long by 10-foot-long wide accumulation table to hold backed-up or accumulated product to nearly 14,000 cans at a required rate of 900 cans per minute (CPM), the company says. Accumulation tables increase line uptime by allowing conveyor systems to store product so that the upstream equipment, in this case a filler, can remain operational at full speed if downstream equipment is stopped. When clear, the table automatically reintroduces the accumulated product to match the down-line equipment surge rate until the table is emptied. The new canning layout incorporates raised rib chain to provide a smooth transfer onto and off of the table and a heavy solid stainless steel floating sweep arm to assist in table filling and emptying. Mass flow to bulk accumulation systems are easily adaptable to almost any round product, minimizing changeover requirements. The amount of increased filler run time is several hours a day and the equipment is expected to provide a full return-on-investment (ROI) in less than a year's time, it says.

Multi-Conveyor

25 Windustrial Road, PO Box 10, Winneconne, Wis. 54986; 800/236-7960; www.multi-conveyor.com.

Wyzo, Ecublens

Vaud, Switzerland; hello@thewyzo.com;; +011/41-79-215-43-79; www.thewyzo.com

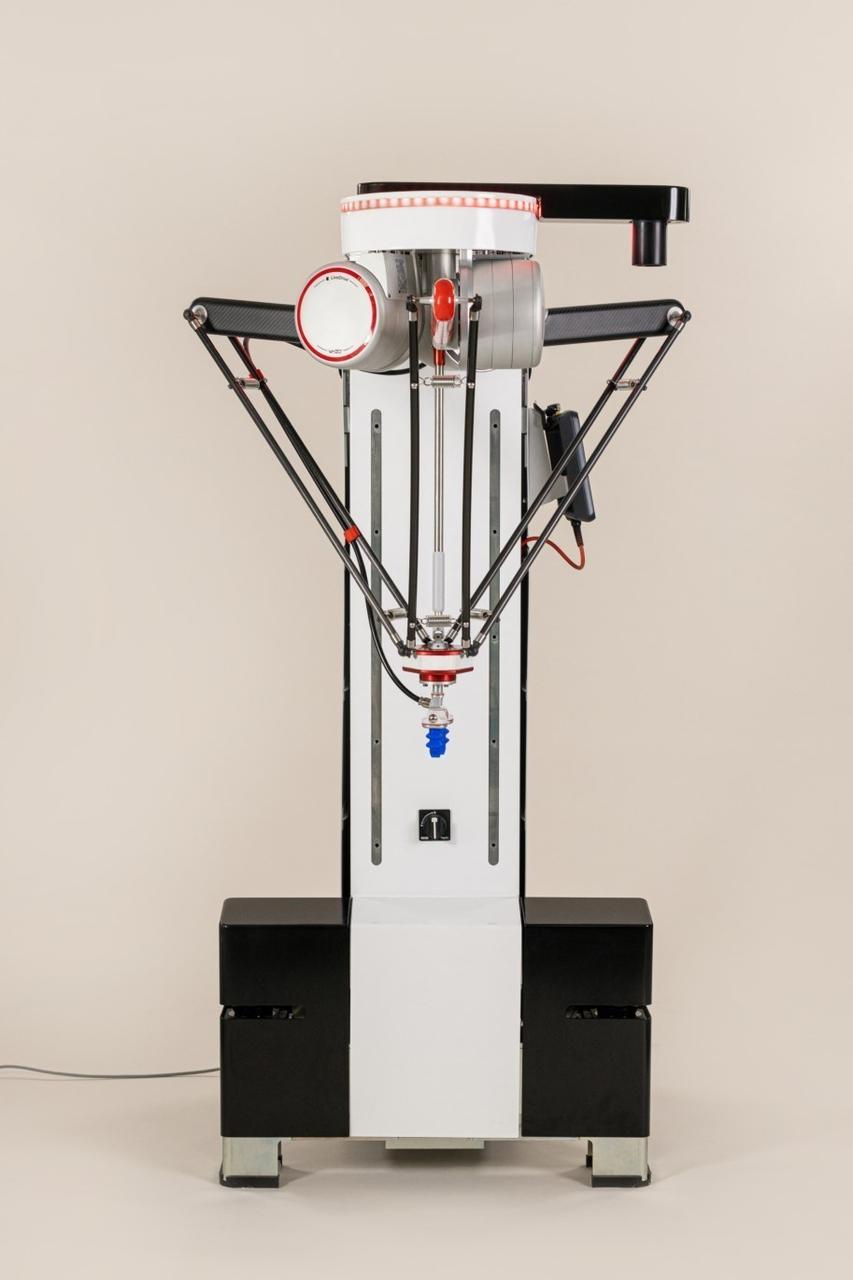

Wyzo Pick-and-Place Sidebot

For companies taking their first steps into automation, Wyzo offers a high-speed pick-and-place sidebot. Combat and agile, Wyzo safely works side-by-side with humans without protective barriers or performance compromises. This new approach to collaborative production is ideal for lightweight applications in food and beverage, consumer goods and more. It also gives operators an assistant to handle day-to-day tasks on the production floor. Building on 20 years of experience in high-speed Delta robots, Wyzo is a fast, compact and flexible sidebot, the company says. Because of the high-tech robotic arm and built-in or external vision systems, the sidebot finds and picks products at 80 cycles a minute, with a payload of half a kilogram, the company says. Through its advanced sensor technology, Wyzo constantly monitors its surroundings for the presence of human activity, allowing it to maximize performance when on its own while slowing down when an operator is nearby. To meet a wide variety of production needs, Wyzo is designed to fit anywhere on the production floor. At less than 0.5 m2 and just 1.80 meters in height, the sidebot fits through standard doors and elevators, offering unprecedented flexibility with a small footprint. It easily can be moved from one workstation to another, eliminating bottlenecks and enabling a fast return-on-investment. The sidebot also is compatible with regular grippers on the market with changeover speeds of less than nine seconds. Additionally, it contains an easy to operate human machine interface (HMI) that requires neither script nor programming, the company says.

SIG Combibloc ECOPLUS

SIG extended its combibloc ECOPLUS aluminum-free packaging material to the fast-growing combiblocMidi family format. Particularly applicable to the dairy industry, the fast-growing square-ish pack taps into demand for more sustainable packaging. Designed to give dairy companies more sustainable options for aseptic cartons, the square-ish cartons are designed to help companies differentiate their dairy products and shape the trend for innovation, the company says. Launched in 2010, combibloc ECOPLUS leads the industry as the first and only aluminum-free packaging material for aseptic carton packs. Additionally, it is made from 82% renewable paper board. The ultra-thin polymer layers are designed to contain and protect long-life milk products. The new sustainable pack offers on-shelf appeal and stand-out environmental credentials, and is central to the company’s commitment to partner with customers and go Way Beyond Good for people and the planet.

SIG Combibloc Inc.

2501 Seaport Drive, Chester, Pa., 19013; 610/546-4200; www.sig.biz.

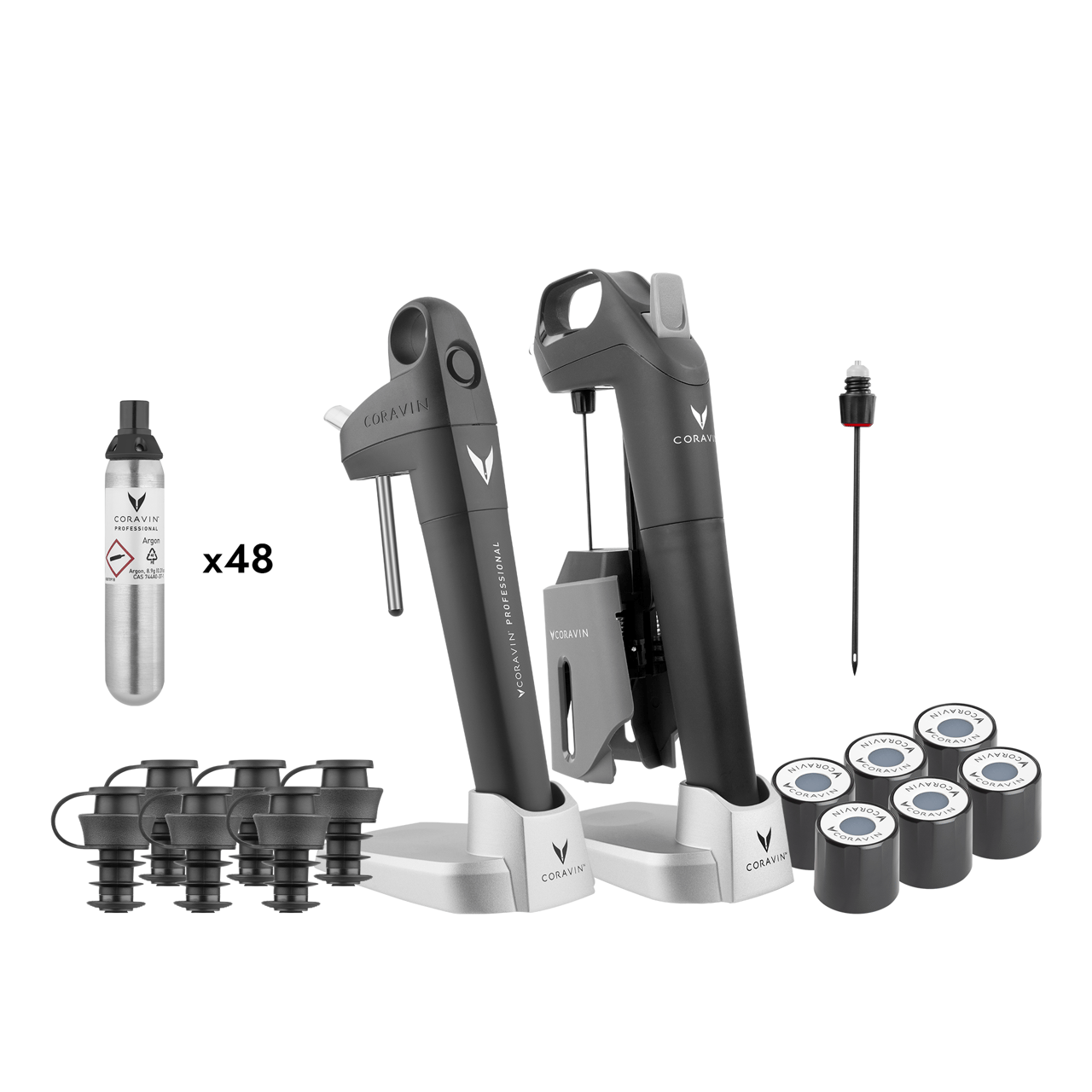

Coravin Professional Wine Preservation Kits

Coravin Inc. launched its new Professional Wine Preservation Kits that are specifically designed for on-premise partners (restaurants, bars and wineries) to increase revenue and profit from wine sales as they reopen and rebuild following the pandemic. Available in four models — the Coravin Pro Reserve, Coravin Pro Select, Coravin Pro Premier Cru and the Coravin Pro Grand Cru — the kits include a variety of devices and replenishment items to enable on-premise partners to cost-effectively expand and enhance their by-the-glass offerings, the company says. The new Coravin Model Three Pro and Coravin Pivot Pro systems sport an elongated architecture and accommodate the larger Coravin Pure Pro Capsules that contain 30% more Argon gas. The number of 5-ounce glasses of wine that can be poured from each capsule range from 20 to 25 on a single capsule (vs. 15-20 with standard models). The Coravin Model Three Pro, part of the Timeless series, features a non-coring needle to pour a glass without removing the cork and lets venues pour a sip, a taste or a glass from virtually any bottle and preserve the remainder for months or even years. On the other hand, the Coravin Pivot Pro provides as many as four weeks of preservation, making it optimal for everyday and step-up wines that turn more quickly. The rapid-pour design delivers a 6-ounce glass in eight seconds, so no time is lost during busy service hours.

Coravin Inc.

28 Crosby Drive, Suite 101, Bedford, Mass. 01721; 781/262-3516; www.trade.coravin.com.

White Labs PurePitch Next Generation

White Labs is raising the bar in the art of brewing beers through its PurePitch Next Generation. Available in all-new optimized packaging to help commercial brewers make the best beer possible, PurePitch is available in two strains: WLP001, California Ale Yeast, which is known for its clean flavors and hardy fermentations, and WLP066, a London Fog Ale Yeast best used in New England-style IPAs, the company says. Backed by more than 25 years of scientific exploration and technological innovation, White Labs’ next generation 1.75-liter, two-layer film packaging is equipped with handles and a connectable port for seamless closed-system inline yeast transfers. This makes it easier for commercial brewers to pitch yeast, while preventing contamination. Each package of PurePitch Next Generation goes through 38 quality checkpoints before it reaches the brewer, ensuring the yeast is the most verifiably superior yeast available, it says. The new packaging also includes a QR code with on-demand quality control data including precise cell counts and strain-specific information, along with detailed usage instructions.

White Labs

9495 Candida St., San Diego, Calif. 92126; 858/693-3441; www.whitelabs.com.

Dearborn, Mich.-based Ford announced that it is acquiring Electriphi, a California-based provider of charging management and fleet monitoring software for electric vehicles. Electriphi’s team and services will be integrated into Ford Pro — a new global business within Ford committed to commercial customer productivity and to developing the most advanced charging and energy management experiences. Ford Pro estimates that the depot charging industry will grow to more than 600,000 full-size trucks and vans by 2030. This acquisition supports Pro’s target to capture more than $1 billion of revenue from charging by 2030. Customers in North America can sign up for Electriphi charge management services now at electriphi.ai. Charging services will launch in Europe at a later date. The Electriphi acquisition was expected to close in July. Terms were not disclosed.

Acquired Data Solutions (ADS), Washington, D.C., entered into a new partnership with United Kingdom based-Bytronic Vision Automation, designed to streamline production and improve the quality of beverage packaging to enhance shipping integrity and outcomes. Throughout the pandemic, the beverage industry saw sustained increases in demand that necessitated improved packaging processes. Tools such as body temperature elevation measurement and metrics used to screen for COVID-19 now are being used in combination with HotSpot, a fully integrated, contactless quality control system designed to test the integrity of the hot glue used in cardboard and paperboard packaging. For instance, a FLIR thermal imaging camera is used to “see” heat from the glue, which allows the HotSpot system to check the temperature and application of the seal itself, and then use optical cameras to ensure flaps are folded correctly.

In June, Southampton, Pa.-based NewAge Industries, celebrated the 10th anniversary of its rooftop solar array. The plastic and silicone tubing manufacturers had more than 4,000 solar panels installed on its rooftop in 2011. Today the array supplies a good portion of the company’s electricity needs, and the same sustainable energy source is being considered for NewAge’s Warrington, Pa., facility, which is undergoing renovations. As a Certified B Corporation, the company works continuously on green initiatives, it says.

United Kingdom-based Dantex Group welcomed Richard Bunney to its executive team. As commercial director, Bunney will focus on commercial and sales responsibilities for the UK market, including international business development for the company’s can business division. Reporting directly to Dantex CEO Ben Danon, Bunny will infuse new energy and ideas into the company’s Kettering office and handle sales, business development and new product development. He brings experience in graphics and packaging from Windeleve and Ball Corp.

The Smurfit Kappa Bag-in-Box division announced the completion of a $14.2 million investment in a new flexible material production facility at its Ibi, Spain-based plant. The investment has resulted in the addition of an extra 4,300 meters of production area with high-tech and advanced machinery, which allows for more specialization in the manufacturing of film. The integrated production model not only means quicker and more efficient service of bag-in-box packaging solutions, but up to 21% less carbon dioxide emissions, the company says.

Clean Energy, Newport Beach, Calif., introduced a new company logo, a cornerstone of an entirely new brand identity that aligns with its growing commitment to expand its renewable fuel solutions. This includes investing in the development of renewable natural gas (RNG) from dairies and other agricultural facilities independently and with partners TotalEnergies and bp. As part of its new branding, Clean Energy also launched a new website, cleanenergyfuels.com, which provides information on the company’s focus on providing beginning-to-end solutions to meet the growing demand for RNG, which represents 70% of the fuel sold at Clean Energy’s nationwide network of stations, it says.

August 2021 | bevindustry.com