Supplier's

Marketplace

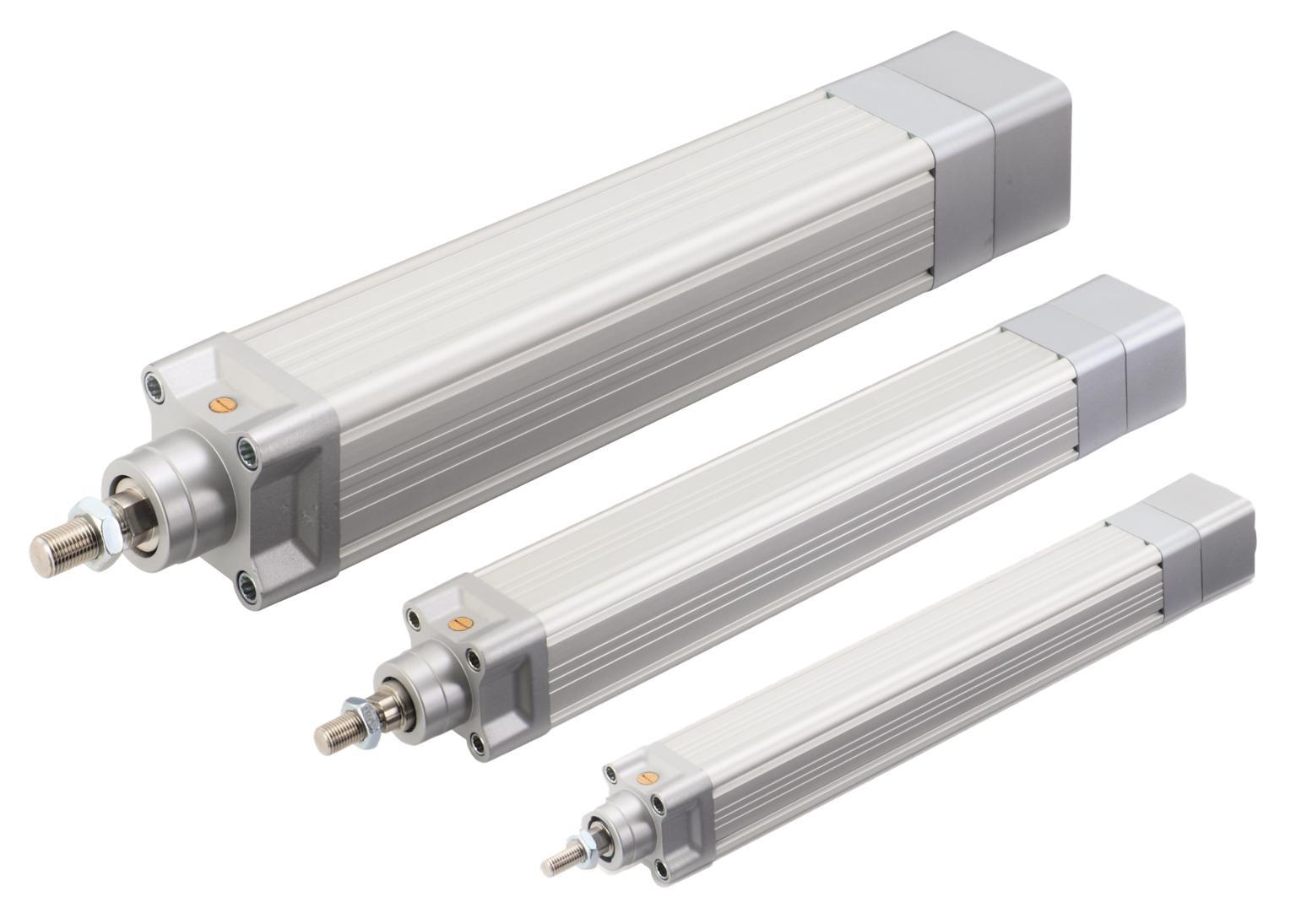

Emerson launches line SPRA Electric Actuators

Emerson launched AVENTICS Series Servo Profile Advanced (SPRA) Electric Actuators. The new, versatile line contains precise and highly repeatable rod-style cylinders, it says. Emerson’s actuator line offers three screw technologies, including a precision ball screw, a cost-effective lead screw and a roller screw, the company notes. The ball screw provides durability and accuracy, while the lead and roller screws support precision, speed and heavy loads, it adds. In a statement, Linda Schwartzen, product marketing manager at Emerson’s AVENTICS actuator business, noted that the SPRA actuators “cover most machine automation applications” because of the four sizes and various mounting options. The range of available cylinders allows users in industries like packaging or food and beverage to “configure electric actuators to meet exacting application requirements, such as improved sustainability or efficiency” as opposed to standard approximation. Additionally, online tools are available so users can size and customize electric actuators without software installation or registration. It allows for a direct download of CAD files, which contain information about motor adapters and mounting options. “ … Our online calculation tool and configurator ensures the appropriate implementation and can meet exacting application requirements,” Schwartzen said.

Emerson

8000 W. Florissant Ave., P.O. Box 4100, St. Louis, Mo. 63136; 314/553-2000 emerson.com

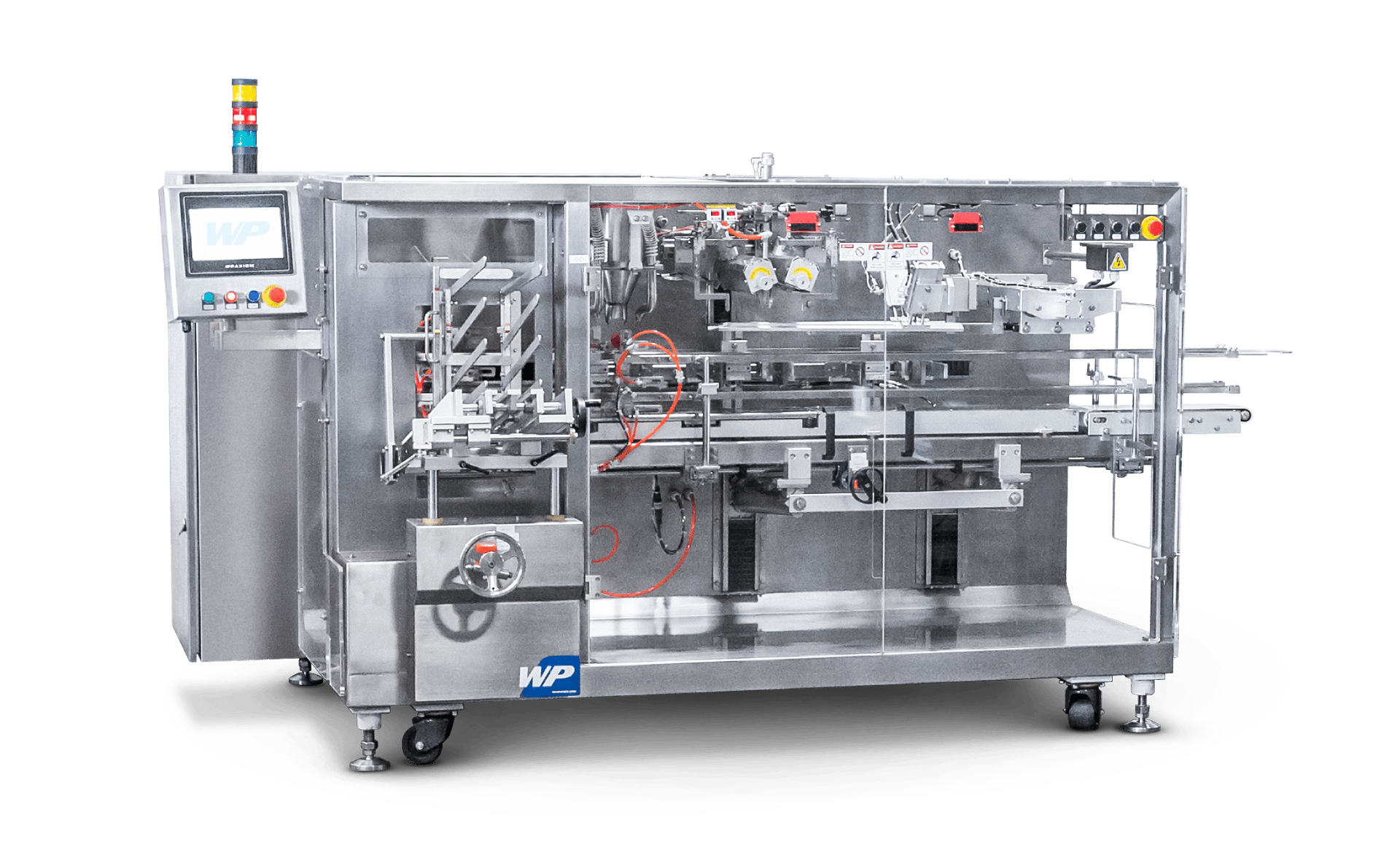

New automated coffee bagging system from WeighPack

WeighPack Systems Inc. launched a new coffee bagging systems for premade box gusset bags, which the company says is designed for packaging other powder or granule products where such bags are necessary. The automated systems, built entirely around the client’s existing bag sizes, uses a screw conveyer to move coffee grounds from a hopper up to the Star Auger powder weigher. After being weighed, the coffee moves into the Swifty Bagger Box Gusset bagging machine to be dispensed into premade bags, which are then tucked at the sides and sealed at the top. The bags are then conveyed to the WeightCheQ, a check weigher, to ensure that each bag meets the weight tolerance before it is accumulated on a rotary table. This WeighPack system includes features, like a bag shaker to settle the product and a project rejection system to prevent heavier bags. In a statement from WeighPack, Nick Taraborelli, vice president at Paxiom Group, said the integrated packaging systems “fill up to 1,500 bags per hour to meet the needs of the most progressive coffee retailers.” Taraborelli noted that larger wholesale clients can expect to see 600 of the larger bags filled each hour. “By combining our new box gusset bagger with our auger coffee filler and downstream check weigher, our clients get a turnkey system that’s easy to integrate so they can ramp up production immediately,” he said.

WeighPack Systems Inc.

5605 Rue Cypihot, Saint-Laurent, QC H4S 1R3, Canada; 514/422-0808; weighpack.com

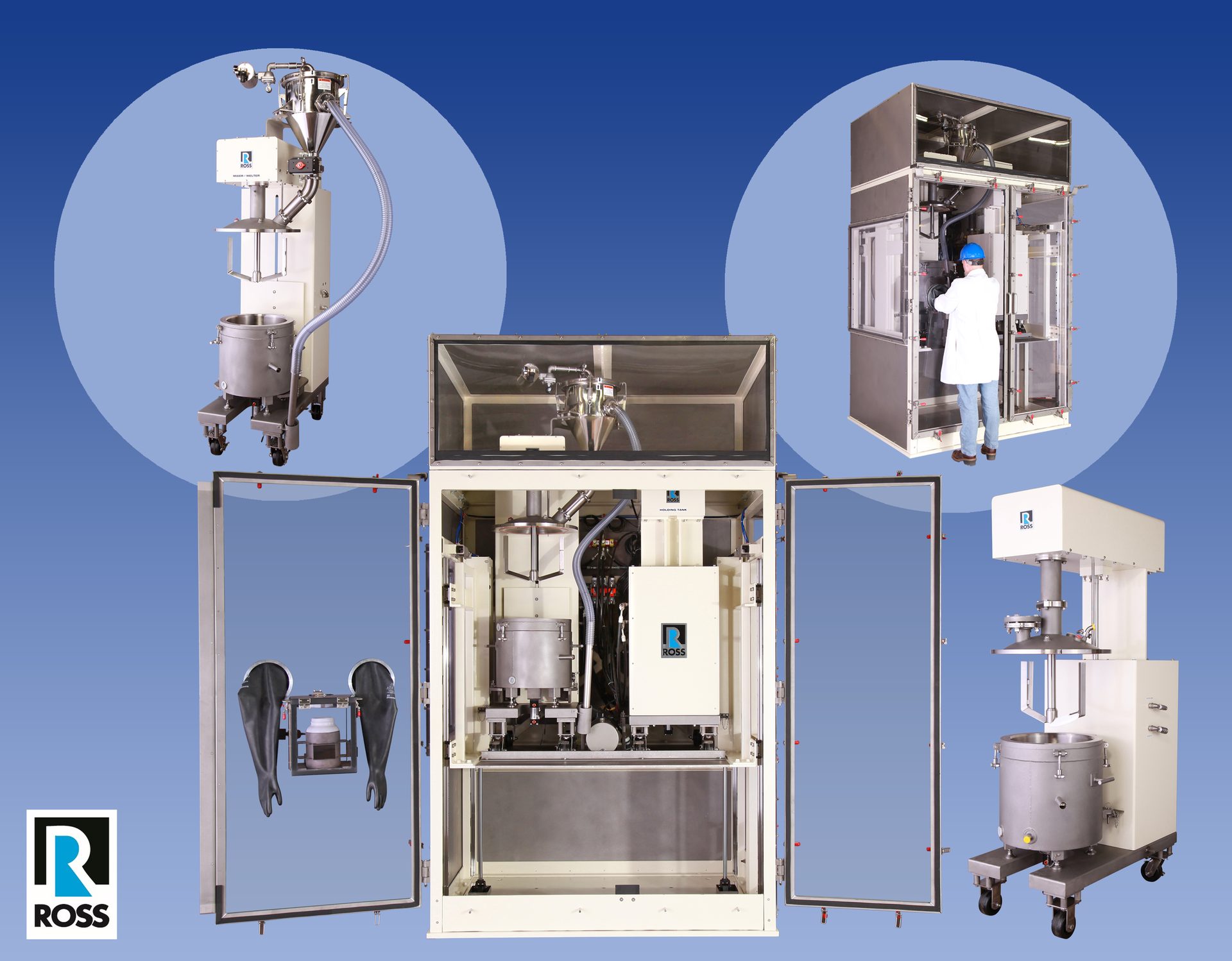

ROSS creates mixing/melting and holding tank system

ROSS created a mixing/melting and holding tank system. The custom-designed system is the latest innovation that allows users to produce highly potent and reactive materials at 350 degrees Fahrenheit and as much as 10 psig internal pressure, the company says. Additionally, it contains an operator-friendly safety glovebox with a pressure-rated sealed enclosure. The system has two mixers that are both equipped with a two-wing anchor agitator, Teflon scrapers and jacketed 6-gallon vessel. One function serves as a mixer/melter connected to a vacuum powder loading system, while the other serves as a holding tank. Gravity feeds the finished product from the holding tank into a downstream coating machine. The mixers have the ability to be lowered into a position for maintenance and then raised to an operating height, where gravity will feed product from the melter to the holding tank, it says. A hot oil heater and chilled water cooler are supplied as well, it adds.

Charles Ross & Son Co.

710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-ROSS; mixers.com

ThruWave announces problem-detecting program, INSIGHT

ThruWave, a tech startup, announced a new quick start program: ThruWave INSIGHT. The program solves operation issues in a variety of industries, including challenges that occur during manufacturing and outbound shipping. Because many of these problems are difficult or impossible to detect, ThruWave INSIGHT automates the inspection process, the company says. The standalone solution doesn’t require integration to existing applications, it adds. ThruWave INSIGHT scans the conveyor of closed cases and totes, creates a 3D image in real-time, and then analyzes the images to identify anomalies, it notes. “ThruWave INSIGHT is human safe. It requires no additional training, detects materials in addition to metal, and provides product context like condition, contraband, counts and volume at conveyor speeds of up to 600 feet [a] minute,” said Pieter Krynauw, CEO of ThruWave, in a statement. “It can be integrated to existing conveyor and robotic material handling systems for immediate use and operational improvement.” The program also provides on-going, data-driven reports, which “quantify previously undetectable anomalies that are critical to developing countermeasures required for operational and business improvement,” the company says. ThruWave’s program is appropriate and cost effective for those searching for regular analytics to decide whether certain problems are improving or worsening, it adds. The program starts at $4,000 a month with an initial three-month contract.

Spencer Strainer releases self-cleaning filter

The GS-288-C is the latest industrial-grade self-cleaning filter from Spencer Strainer — a company that’s been producing a patented strainer for more than 25 years. The filter can continuously process flows as fast as 2,500 gpm without needing downtime for filter changes, because it doesn’t have any bags or elements. The elimination of bags or elements can help companies achieve their sustainability goals, the company says. The filter is made of 316-liter stainless steel and is a sealed device, so product will stay within the piping and out of the atmosphere. Spencer Strainer says these filters are “a reliable, cost-effective solution for many types of oil, acrylic, polymers, paint, biofuel, toothpaste, caulk, bath tissue, wastewater and more.” The product enters the strainer through an inlet, and the filtration process occurs from the outside in. Particulate that has been screened then accumulates within the canister and is purged through the bottom drain as necessary. The purged particles are then piped away for disposal, recycling or reuse. The company says the strainers are “suitable for aseptic operation and work well as pre-filters upstream of membranes, centrifuges and other fine filter media.” The GS-288-C has a 2 HP, three-phase motor, with Delrin stationary wiper blades.

ThruWave Inc.

3534 Bagley Ave. N., Seattle, Wash. 98103; thruwave.com

Spencer Strainer

6205 Gheens Mill Road, Jefferson, Ind. 47130; 800/801-4977; spencerstrainer.com

Daniel Schumacher is the latest addition to Toyota Material Handling’s (TMH) executive team. He was recently appointed as the Director of Information Technology (IT). Prior to joining the TMH team, Schumacher worked as Global Director of IT Applications and Digital Innovation at Komatsu, another manufacturer of construction and industrial equipment. “We are excited to add Daniel to our Toyota family, and we look forward to seeing what he can accomplish in this new role,” TMH president and CEO, Bill Finerty, said in a statement. “Daniel’s strong background in technology speaks for itself, and his character will make him a perfect culture fit at TMH.” Schumacher says the opportunity to work at a world-class company and brand like Toyota is “an honor,” and he is looking forward to using his “past experiences and passion for technology” to help the company achieve its goals.

The United Kingdom’s Meech International recently released a white paper detailing the importance of clean, neutrally charged components in electric vehicle (EV) batteries. Because global demand for EV has continued to increase, the company says that battery performance, reliability and safety all play a “critical role in the success of any EV.” Poor performance or failure of an EV battery can ruin the reputation of the car manufacturer’s reputation. In the white paper, Meech examines how specialist suppliers of contamination removal and static control can play a crucial role throughout the production process, “to ensure clean and safe environments for the optimum manufacture of high-quality, high-performance cells.” The company says they offer a “dedicated approach” to surface contamination and static charge removal, with a variety of solutions that are specially tailored to the battery manufacturing industry — matching the material, process and contamination type.

Leading-edge safety technologies developer Bendix Commercial Vehicle Systems will continue to comply with Federal Motor Carrier Safety Administration (FMCSA) regulations thanks to an exemption made permanent. The rule change impacted where vehicle safety devices could be mounted onto commercial motor vehicle windshields, and it became effective in May. Previously, devices were required to be mounted “not more than 4 inches below the upper edge of the area” swept by windshield wipers. Now, after making a temporary exemption permanent, the distance has increased to 8.5 inches. Video cameras like those from Bendix will remain compliant under this rule change. “The amendment will make it easier to implement advanced technologies that use multiple sensors, like Wingman Fusion, without fleets, drivers and truck manufacturers having to worry about windshield clearance rules,” said Fred Andersky, Bendix director of government and industry affairs, in a statement.

INX International Ink Co., the third largest producer of inks in North America, is expanding its customer information outreach once more through additions to the INX Troubleshooting Guide App. The solution extensions on the app come after the company introduced the Printer Space blog in an effort to “provide beneficial information” to customers. The app now has information for uses of water-based Flexo inks, which is now the 10th guide available for customers to find answers. INX says the app is able to identify problems and symptoms while also recommending solutions in nine different languages for three metal decorating guides. “This latest update with the Troubleshooting Guide App is indicative of our commitment to improve the flow of information to our customers,” said Renee Schouten, INX’s vice president of marketing, in a statement.

Fresh food and beverage packaging company Pactiv Evergreen Inc. launched a new “Zero Waste Implementation Guide.” The guide, which is available for free download online, will serve as a resource to “help foodservice establishments improve their waste diversion rates,” the company says. Foodservice programs at stadiums, universities and arenas definitely will benefit from this guide, it adds. “As the provider of the broadest selection of sustainable foodservice packaging in North America, Pactiv Evergreen is committed to providing the tools operators need to lessen the environmental impacts of their operation,” said Lynn Dyer, chief sustainability and public affairs officer at Pactiv Evergreen, in a statement. “This guide is an example of our commitment to serve as a partner to our customers. It exemplifies our company’s purpose of ‘packaging a better future’ by making a positive impact with our customers, communities and the environment.”

Food and beverage industry cloud-based data solution provider Encompass Technologies, based in Fort Collins, Colo., acquired vintrace, a cloud-based winery production software, in June. Now, Encompass can serve a broader market of beverage manufacturers worldwide, offering end-to-end supply chain insights with the expanded digital database so companies can grow their business, it says. vintrace cloud-based software is trusted by 670 wineries globally, with a 98% user satisfaction rate, it adds. With vintrace, the Encompass network now supports 150,000 brands and 1.1 million retailers. “vintrace brings the wine production expertise and Encompass offers the breadth of ERP, CRM, eCommerce and data solutions that wineries need,” said Jonathan O’Neil, CEO of Encompass, in a statement. “Together, we are supporting and developing comprehensive ERP solutions which align with our strategy of enabling beverage manufacturers to innovate new brands and expand their portfolio of products, including wine.”