Supplier's

Marketplace

Agr’s Gawis 4-D measurement system

Agr International Inc. introduced its Gawis 4-D measurement system with robotic handling. Designed to automate a number of critical bottle and preform measurements into a single operation, this new laboratory test system provides a new level of measurement capabilities to support the design, process and quality management of plastic containers and preforms, the company says. Used in conjunction with the Gawis AF robotic handling system, the Gawis 4-D system offers additional flexibility by performing numerous dimensional and thickness measurement operations, typically performed by hand, on individual bottles or preforms into a single hands-free operation, completed in a matter of seconds. The addition of robotic handling maximizes testing throughput while freeing laboratory personnel for other more critical tasks, it notes. Central to the system is a precision pick-and-place industrial robot that manages sample selection and placement of samples into the Gawis 4-D for measurement. For sample management, samples are hosted in a multi-level carousel that is outfitted with rotating tiers designed to positively position samples for robot access. The tiers can be configured to accommodate bottles from single or multiple mold rounds, or a complete mold set of preforms.

Agr International Inc.

615 Whitestown Road, Meridian, Pa. 16001; 724/482-2163; www.agrint.com/gawis4d.

Siemens Industry Inc.

General Motion Control, 390 Kent Ave., Elk Grove Village, Ill. 60007; 847/640-1595; usa.siemens.com/simotics-s1fs2.

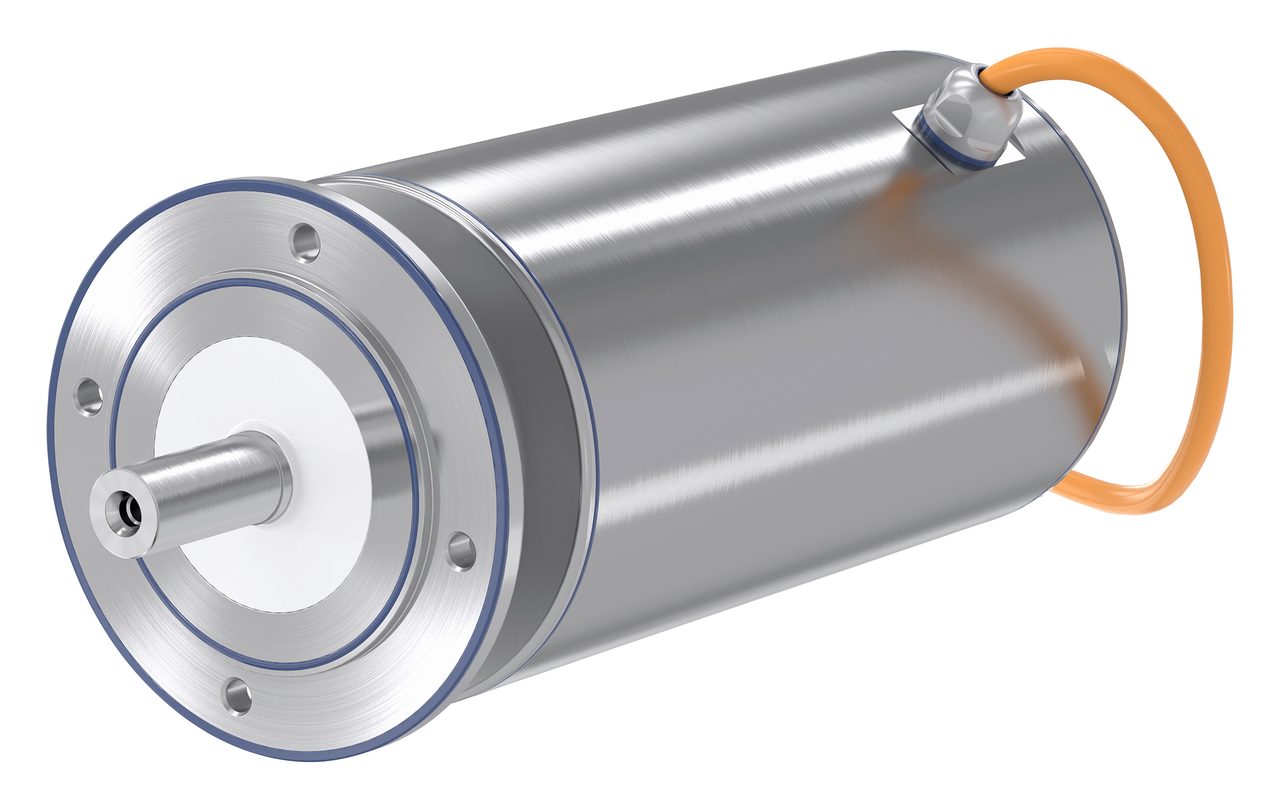

Siemens Simotics S-1FS2 servomotors

Siemens Industry Inc. offers the new SIMOTICS S-1FS2 servomotors for food, beverage, sterile packaging, pharmaceutical and other process applications. The stainless steel housings are suited to the highest standards of hygiene and cleanliness and are available in three sizes, from 0.45 to 2kW (0.60 to 2.68 horsepower) with torque from 3.1 to 14 Nm (2.28 to 10.32 foot-pounds), the company says. Crafted with housings of 1.4404 (AISI 316/316L) stainless steel, EPDM seals and bearing grease with NSF H1 approval, these new servomotors are highly resistant to corrosion and acidic chemicals found in process industries. Additionally, the extremely high degree of protection is in accordance with IP66/67 standards on the entire motor, with IP69k (30-bar) protection provided on the motor housing. Added features included are high dynamics due to low inherent inertia plus high overload capacity for use in pick-and-place applications, plus precise movement of heavy loads, it says. The SIMOTICS S-1FS2 family of motors is suitable for clean-in-place (CIP) processes and for use with all commercially available cleaning agents used with washdown motors. The motors are especially designed for the 3-A (U.S.) and EHEDG (Euro) requirements of the food and beverage industries.

Wilkens-Anderson Co.

4525 W. Division St., Chicago, Ill. 60651; 773/384-4433; www.wacolab.com.

Digital Enamel Rater III

Wilkens-Anderson Co. offers its new Digital Enamel Rater III for fast, accurate quality inspection measurements of the enamel coating on the inside of food and beverage cans. The device displays an index of the metal exposure due to incomplete enamel coverage on a digital LED display. Among the features are a new LCD screen for easy menu selection, adjustment and settings; a 5-digit digital LED display for milliamp readings; and a 2-digit LED timer display, the company says. Voltage is set at 6.3 VDC, which is adjustable from 4-9 VDC. Operating range is 0-500 ma with an improved accuracy resolution of 0.01 ma. Preset to an industry standard four-second mode, the rater also can be put into continuous or programmable modes. In programmable mode, the operator can select customized time settings. Both RS232 and USB ports allow for easy transfer of data to computers, printers or data collection systems, the company says.

Allpax onsite and remote-access technical support

Allpax, a product brand of ProMach, offers a tiered approach to service contracts for both onsite and remote-access technical support that is provided by the same specialists who build the automated retort systems. The program ensures that customers facing staffing challenges have access to skilled support personnel and a comprehensive strategy for maintaining their retort operations at peak efficiency, the company says. One of the novel aspects of the new program is that service contracts are customized to the situation of the plant. Three levels of contract services are available for onsite and remote support, which provides a starting point for identifying the optimum support strategy for each plant. Once the skills, time and tasks required on an annual basis are defined, a meeting is prescheduled with mechanical and controls personnel to be onsite for preventive or routine maintenance and/or to be available for remote diagnostics. Contracting for the ideal level of maintenance beforehand lowers the cost of support as compared with reactive support requests, and ensures the right resources are available at the right time. Service by original equipment manufacturers reduces risk, while ensuring peace of mind.

Alpax

453 Northpointe Court, Covington, La. 70433; 985/893-9277; www.alpax.com.

ROEQ TMS-C1500 boosts payload, lifting

ROEQ launched two new top modules designed to boost the payload and lifting capabilities of autonomous mobile robots (AMRs). The ROEQ TMS-C1500 allows MiR AMRs to transport as much as 1,500 kilograms (kg), or 3,307 pounds. The AMR also adds flexibility to lifting applications, enabling end users to achieve their productivity goals and overcome labor shortages while avoiding the need to make massive additional capital investments in automation, the company says. The new ROEQ top module TMS-C1500 combined with the new S-Cart1500W shelf cart increases the payload capabilities of MiR’s MiR500, MiR600, MiR1000 and MiR1350 AMRs. Using the TMS-C1500 top module, a MiR1000 or MiR1350 AMR can be deployed on applications with payloads as much as 1,500 kilograms, enabling MiR AMRs to be deployed in applications with heavier payloads than ever before. Similarly, the TMS-C1500 allows a MiR500 or MiR600 AMR to be deployed on applications with payloads as much as 800 kilograms. Another benefit is that the TMS-C1500 operates without a docking station, enabling the mobile robot to pick up and drop off the shelf cart in free space and with precision.

ROEQ

Glasvænget 9, 5492 Vissenbjerg, Denmark; +011/45-61-31-06-93; www.roeq.dk.

St. Louis-based TricorBraun acquired premium glass packaging provider Vetroelite and now operates as Vetroelite, a TricoBraun company. Headquartered in Milan, Italy, Vetroelite has a strong footprint in Europe and North America and provides high-quality, innovative packaging solutions for the spirits, gourmet food and wine industries. The acquisition strengthens TricorBraun’s European footprint and continues the company’s global expansion. All Vetroelite team members, including CEO Daniele Feletto and the company’s leadership team, are part of TricorBraun and will work out of the company’s existing locations.

The CC-Link Partner Association (CLPA), Vernon Hills, Ill., named Roy Kok as senior partnerships and alliance specialist to enhance the organization’s ever-growing global channel of automation vendors. In the newly created position, Kok will be responsible for driving new business initiatives across North America aimed at growing participation in the CLPA. He also will help strengthen Mitsubishi Electric’s e-F@ctory Alliance program, where members cooperate to offer flexible, optimized automated solutions for customers across a wide variety of industries.

Automation24, an online shop for industrial automation technology, announced that Schmersal Inc. machine safety devices now are available to U.S. customers. A global leader in machine safety, Schmersal produces innovative mechanical and electrosensitive switching devices that comply with current safety standards, the company says.

The Washington, D.C.-based Reusable Packaging Association introduced a new podcast series, “Reuse on Replay: Straight Talk with Circular Thinkers.” Experts and thought leaders from around the reusable packaging industry discuss the circular economy, sustainability, reusable packaging implementation, and other timely topics. Listen on Reusables.org or one can listen and subscribe on their favorite podcast platform.

Zeus Electric Chassis Inc. (Zeus), Minneapolis, announced plans to collaborate with JB Poindexter Co.’s entity-attribute-value (EAV) on Class 4, 5 and 6 electric work trucks. The partnership puts the companies on track to develop and commercialize market-leading electric work solutions in 2022. Initial development efforts will focus on the integration of JB Poindexter’s commercial truck bodies, utility truck bodies and vehicle cargo management systems with the Zeus Power Platform, an all-electric cab chassis. Zeus will leverage JBPCO’s North American operational footprint to help establish a nationwide service and support network for Zeus products.