Supplier's

Marketplace

Weidmuller USA expands PCB product portfolio

Provider of smart industrial automation and connectivity products Weidmuller USA recently introduced the new OMNIMATE 4.0 PCB Terminal Blocks. The new blocks are part of the MTS 5 product series, and mark an exciting expansion of the company’s PCB product portfolio. They feature Weidmuller’s innovative SNAP IN technology, providing the most efficient wiring, and signal transmission in many industrial sectors, the company notes. The OMNIMATE 4.0 Terminal Blocks include some industry-leading features, such as ready-to-robot optimization, easy handling of push-in buttons when rewiring, wire-ready parts and options for screw, push-in and SNAP IN connectivity. “Customers can now connect their devices more efficiently because the OMNIMATE terminal blocks are fast, flexible and reliable,” said John Froustet, director of device and field connectivity division Americas, Weidmuller USA, in a statement. “Due to OMNIMATE’s modular design and digitalized configuration through the web configure, there are infinite design possibilities to meet the automation and connectivity needs of any business.” Additionally, the new blocks feature a 5 mm pitch, as well as vertical and horizontal orientations in two through 12 positions. An optical and acoustic safety indicator shows when wiring is complete, the company says.

Weidmuller USA

821 Southlake Blvd., Richmond, Va. 23236; 804/794-2877; www.weirdmuller.com

New non-marring nozzle latest from EXAIR

EXAIR introduced the new PEEK ½ NPT Super Air Nozzle, engineered to produce powerful blow off without damaging expensive equipment. The company notes that, when working with surfaces and equipment that are sensitive to scuffing or abrasion, it is important to use tools that ensure protection from potential costly downtime and repairs. The PEEK plastic construction provides non-marring protection to production items, as well as “excellent resistance” to damage from harsh chemicals and temperatures as high as320 degrees Fahrenheit (160 degrees Celsius), the company says. The product is “great for blow off, cooling and drying applications” in general industrial or corrosive environments, it adds. Providing hard-hitting blow off, the Model 1106-PEEK Super Air Nozzle reduces air consumption and increases safety. The design is engineered to guide the airflow to a single point of convergence for “strong force and dramatic noise reduction” over typical blow offs, according to the company. EXAIR assures safe operations, because all nozzles from the company are CE compliant and meet or exceed OSHA standards for dead-end pressures, it notes. The new nozzle is designed to “easily replace existing wasteful nozzles or open pipes” in critical applications, the company says. EXAIR’s Super Air Nozzles also are available in Type 316 Stainless Steel and Zinc Aluminum alloy. The nozzles are available in special materials as well upon request to accommodate unique processes.

EXAIR

11510 Goldcoast Drive, Cincinnati, Ohio 45249; 800/903-9247; www.exair.co

Smurfit Kappa unveils sustainable Bag-in-Box film

Paper-based packaging solutions company Smurfit Kappa recently developed a recyclable film to replace nylon, a commonly used material in bag-in-box productions, especially in the United States, the company notes. Smurfit Kappa introduced a polyethylene film, similar to nylon in terms of strength and resilience; however, unlike nylon, polyethylene is recyclable, it says. “Our new Lx polyethylene film is much better for the planet because polyethylene is the most developed recyclability stream in the flexible packaging sector,” said Massimiliano Bianchi, chief operating officer of Smurfit Kappa Bag-in-Box, in a statement. “We are delighted that we can now offer our customers a sustainable alternative, which doesn’t compromise on quality, reliability or safety. This innovative film can replace the nylon used in many different bag types because it delivers undeniable and consistent performance, no matter what the application and requirements.” The Lx polyethylene is the latest addition to the company’s Bag-in-Box portfolio of sustainable films offered globally for different marketing segments and supply chain demands.

Smurfit Kappa Packaging LLC

1301 International Parkway, Suite 550, Sunrise, Fla. 33323; 954/514-2600; www.smurfitkappa.com

Emergent Vision Technologies introduces Eros 5GigE camera series

High-speed camera providers Emergent Vision Technologies launched the Eros camera series. The new camera series will support 5GigE, 2.5GigE and 1GigE speeds through auto-negotiation. The Eros cameras are set to feature the latest Sony Pregius CMOS image sensors, which are offered in Emergent’s 10GigE and 25GigE cameras, but in lower speed, lower cost and smaller-sized camera options. The cameras will still support Emergent’s zero-copy imaging approach, which refers to the use of built-in header splitting features in network interface cards (NICs) to perform zero-copy image transfer, the company explains. John Illett, president and chief technology officer of Emergent, notes that Eros cameras “address the gap that exists in the market today when it comes to zero-copy imaging,” which has become a must-have requirement for achieving top performance in lower speed multi-camera configurations. “RDMA and RDMA over Converged Ethernet v2 (RoCE v2) support zero-copy transfer, but require more FPGA resources to implement, which is more costly than the mature, lightweight GigE Vision Streaming Protocol that Emergent supports,” Illett said in a statement. “As a result, many manufacturers are not supporting RoCE v2 in cameras below 10GigE, but Eros cameras address this lack of support by delivering zero-copy imaging performance for some of the most challenging lower speed multi-camera machine vision applications today.”

Emergent Vision Technologies

2160-955 Seaborne Ave., Port Coquitlam, British Columbia, Canada V3B 0R9; 866/780-6082; www.emergentvisiontec.com

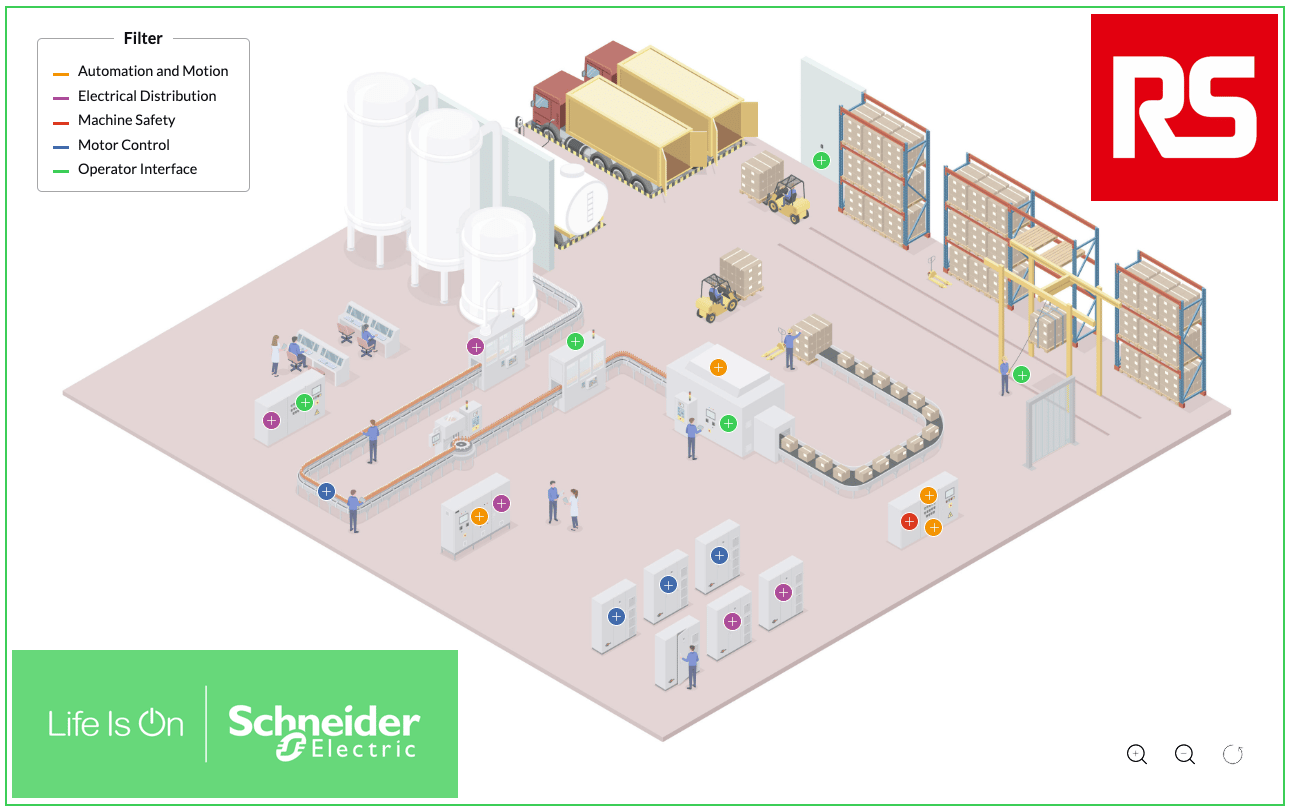

Schneider Electric Factory Visual tool now available at RS

A new interactive 3D tool from Schneider Electric allows users to visualize how various automation and control products could improve operational efficiency, safety, reliability and resilience of the equipment on factory floors. On the RS website, it also provides one-click access to relevant product ranges. The Factory Visual tool features a customizable 3D model of a factory environment and introduces the core product ranges in the company’s automation and control portfolio. The tool also shows how such products can help users. As a default, the digital factory environment is a soda bottling plant that includes a section for material handling, packaging and transport, giving users a general idea of where Schneider Electric products would add value to operations. Those interested in a more tailored experience can contact RS to request a 3D model of their own factory. In a statement, Jannet Betancourt, digital market manager of industrial automation at Schneider Electric, said that the tool allows customers to “make better-informed decisions about products” in relation to their own operations. Additionally, through the RS website, Betancourt notes that customers can not only purchase these solutions, but also can “count on high-quality support for installing, deploying and maintaining them throughout their long lifecycles.”

Schneider Electric United States, North American Division

800 Federal St., Andover, Mass. 01810; www.se.com/us/en

Husky Technologies, Bolton, Ontario, recently celebrated the grand opening of its new service center in Jeffersonville, Ind. The state-of-the-art center, which the company considers “a strategic investment,” comes as Husky celebrates its 70th year anniversary. “With its cutting-edge operational capabilities, this service center represents our vision for the future,” Tony Black, Husky’s president of service, said in a statement. “It sets a new standard in service delivery, offers a comprehensive range of readily available OEM parts, and reaffirms our commitment to our customers in the Americas region.”

Parsippany, N.J.-based Electronic Drives and Controls Inc. (EDC) announced that it has achieved recertification by the Control System Integrator Association (CSIA). “Maintaining our CSIA certification helps promote the documenting of operating procedures that ultimately removes many obstacles to growth,” said Chuck Dillard, vice president of electronic drives and controls, in a statement. “It helps to make sure the business is set up for longevity. Customers want to know you will be there for the long haul and the CSIA best practices committee does a great job providing a road map to that end.”

Washington, D.C.-based Can Manufacturers Institute (CMI) has promoted Scott Breen to senior vice president. “Scott effectively articulates how the attributes of the metal can make it the sustainable solution,” said Robert Budway, president of CMI, in a statement. “His extensive knowledge about sustainability and the circular economy, along with his analytic ability and facilitation prowess, create new energy to effectively fortify the sustainability narrative and further communicate the metal can’s sustainability superiority.”

Norton Shores, Mich.-based Smart Vision Lights (SVL) revealed that its DoAll multifunction light has received UR+ certification from Universal Robots. “With UR+ certification, an entire inspection plan can be programmed with the drag-and-drop interface in the teach pendant, from the positioning of the robotic arm to the acquisition of an image,” said Steve VanderZwaag, vice president of engineering at SVL, in a statement. “Multiple inspection types can be saved and cycled through as needed going forward.”

INX International Ink Co., Schaumburg, Ill.,released its inaugural Sustainability Report, which offers a comprehensive overview of the company’s evolving practices. The 36-page report emphasizes INX’s continuing commitment “to become a greener company, and how it translates into providing customers with best-in-class ink and technology solutions that enable world-class printing standards.” In a statement, INX President and CEO Bryce Kristo said that the company is “dedicated to developing products that create value for our customers and help safeguard our planet.”