Supplier’s Marketplace

Peterbilt

1700 Woodbrook St., Denton, Texas 76205; 940/591-4000; www.peterbilt.com

Smurfit Westrock

1000 Abernathy Road Northeast, Atlanta, Ga. 30328; 770/448-2193; www.smurfitwestrock.com

Peterbilt unveils new LED pod headlights for Model 589

Peterbilt recently announced the availability of its distinctive new LED pod headlights for the Model 589. These new headlights offer greater visibility, enhanced styling and increased overall safety, the company says. The headlights use 30% less power than the halogen equivalent and provide maximum light output with wide range coverage and 45-degree left and right low beams as well, it notes. “The new polished aluminum LED pod headlights on the Model 589 exemplify our efforts to maintain the bold, legendary styling of the Model 589 while helping fleets maximize productivity,” said Jake Montero, assistant general manager, sales and marketing for Peterbilt, in a statement. “Engineered to meet the demands placed on today’s trucks, the LED headlights provide peak performance, safety and reliability.” The company adds that the new LED pod headlights deliver “superior performance” in addition to an extended lifespan thanks to a range of the following features: all LED design with lifecycle exceeding 50,000 hours; individually replaceable modules for easy service; excellent glare control for optimum visibility; cooling managed through solid aluminum forgings and castings for peak performance and reliability; designed to operate continuously in extreme ambient temperatures; integrated lens heaters for clear lenses in inclement weather; and finally, hard-coated protection on external headlamp lenses, safeguarding against ultraviolet exposure and fine sand.

Smurfit Westrock releases EasySplit Bag-in-Box design

Smurfit Westrock launched its latest pioneering innovation, the EasySplit Bag-in-Box design. This innovation was specially developed to meet the upcoming requirements of the Packaging and Packaging Waste Regulation (PPWR). The PPWR will mandate that all packaging achieves at least 80% recyclability. For bag-in-box products, the company explains that this will mean ensuring the box and bag are “easily separable to facilitate recycling.” When properly separated, each component can be recycled in its respective stream, increasing the overall recyclability rate. Smurfit Westrock developed the patented EasySplit Bag-in-Box design, which significantly enhances the ease of separating the bag and box, improving recyclability and ensuring compliance with the forthcoming PPWR. “With the European Commission set to decide on the methodology within the next three years, it is imperative to act swiftly and demonstrate a viable solution to the challenge,” said Massimiliano Bianchi, CEO of Smurfit Westrock Bag-in-Box, in a statement. “Smurfit Westrock is leading the charge in preparing the packaging industry for future regulations by launching our EasySplit Bag-in-Box design. As we continue to educate consumers and stakeholders about the importance of proper recycling practices, Smurfit Westrock remains dedicated to driving positive change and demonstrating environmental stewardship.”

Continental Tire The Americas llc

1830 MacMillan Park Drive, Fort Mill, S.C. 29707; 704/583-4882; www.continental-tires.com

ABB

305 Gregson Drive, Cary, N.C. 27511; 800/435-7365; www.new.abb.com

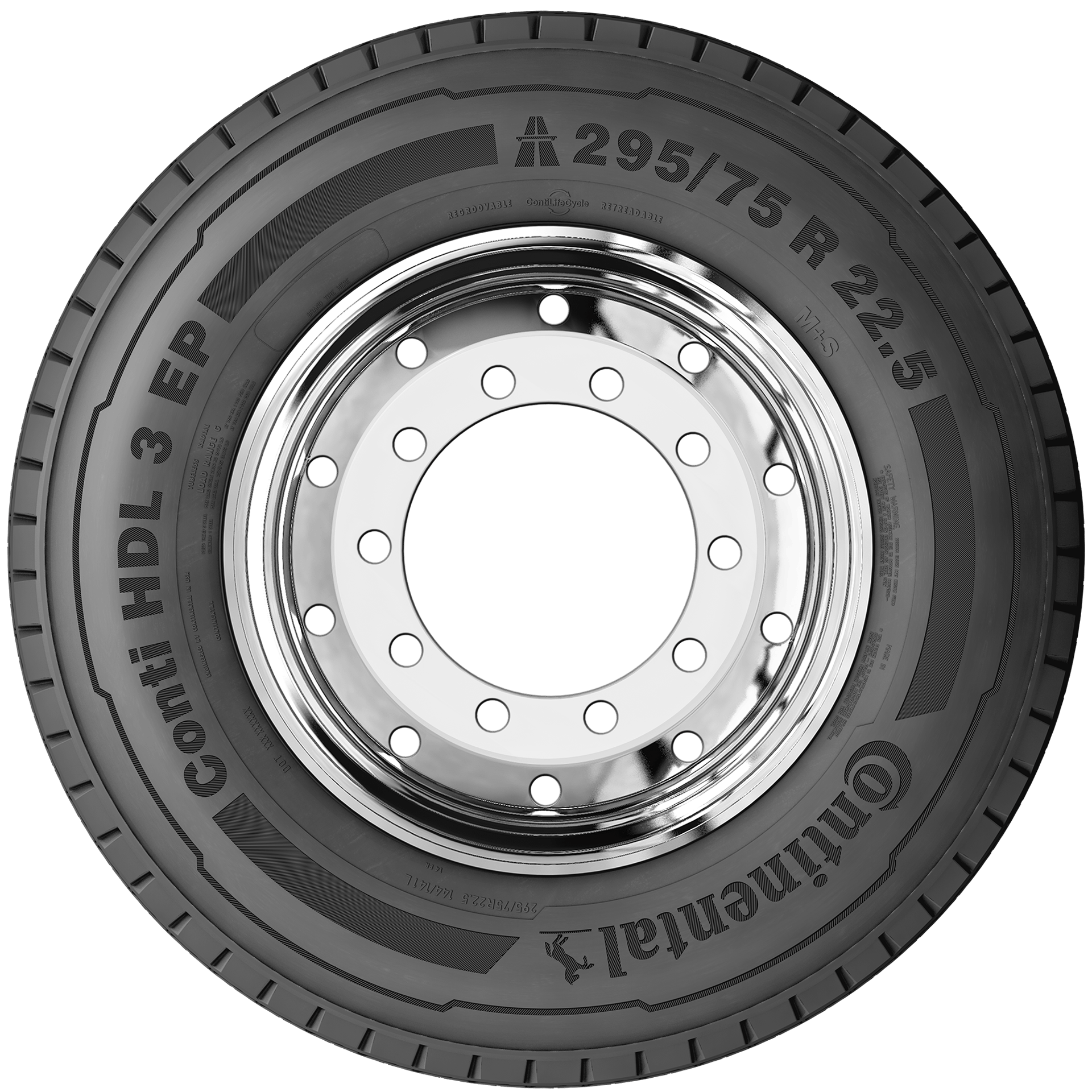

Long haul drive tire latest from Continental

Tire and automotive technology supplier Continental has released a fuel-efficient, long haul drive tire for the United States market. The Conti HDL 3 EP combines high-structure carbon black and silica technology to deliver a well-balanced mix of rolling resistance and durability, the company says. It achieves up to 10% better rolling resistance compared with its predecessor thanks to its polymer matrix-bound silica compound, it adds. The tire is SmartWay verified for Class 8 long haul tractor trailers, making it a top choice for fuel efficiency and performance, it notes. “The Conti HDL 3 EP was purposefully designed with a fleet’s needs in mind — from being built on 3G Casing for maximum retreadability, to its improved rolling resistance and even wear,” said Shaun Uys, head of Continental’s truck tire replacement business in the U.S., in a statement. “This premium long haul tire was designed to help fleets achieve their lowest overall driving cost.” The closed shoulder design enhances mileage and rolling resistance, while its optimized footprint ensures even wear, Continental notes. It features innovative groove geometry that reduces stone retention, offering up to 15% improved cut and chip resistance, further expanding its lifespan. The Conti HDL 3 EP is built on Continental 3G Casing that has a 240-245 mm retread width, featuring a state-of-the-art belt package that reduces head, increases durability and maximizes retreadability. For optimal performance and uptime, the tire can be paired with Continental’s ContiConnect Live digital tire monitoring system, the company says.

ABB optimizes Baldor-Reliance Food Safe stainless steel motors

Manufacturer of NEMA motors, ABB, has elevated its Baldor-Reliance Food Safe stainless steel motor portfolio with a streamlined three-lead electrical connection design. This updated design delivers a superior experience for food and beverage processing operations, the company says. The solution is engineered to simplify installation, enhance reliability and improve workplace safety, all while seamlessly integrating with existing 460V systems, it notes. “This new configuration of the Baldor-Reliance Food Safe stainless steel motor is a testament to ABB’s commitment to supporting our customers with reliable, efficient and industry-leading technology,” said Brandon Cancilini, global product manager for ABB’s NEMA Motors Division, in a statement. “ABB is dedicated to developing solutions that address the unique demands of food processing environments.” The optimized design reduces installation time and simplifies the setup process, according to the company. By minimizing the number of leads, the risk of connection errors is decreased — this results in greater reliability with fewer interruptions, it says. The enhancements allow facilities to boost productivity while also lowering maintenance costs and reducing downtime, the company notes. The Baldor-Reliance Food Safe stainless steel product lineup, featuring 1-5 horsepower, three-phase motors, is engineered to meet diverse operation needs with advanced performance and durability. The stainless steel enclosure features smooth, crevice-free surfaces as well as a self-draining design, which prevents food particle buildup and ensures thorough cleaning and minimizes contamination risks. All Baldor-Reliance Food Safe motors are built with corrosion-resistant stainless steel, providing IP69 ingress protection. The motors can withstand high-pressure, high-temperature washdowns, while exceeding rigorous sanitary standards and eliminating the need for motor shrouds, the company says.

In an effort to protect bottle cap quality, Califia Farms, Los Angeles, installed an advanced V31 vision inspection system from Mettler-Toledo, Columbus, Ohio, on its main packaging line to help ensure every bottle leaving the facility meets the company’s standards. “We had two main goals for our new vision system,” said Keith Meadows, director of engineering at Califia Farms, in a statement. “The first was to verify proper cap placement on every bottle to maintain package integrity, and the second was to monitor our upstream filling and closing equipment to optimize production efficiency. We considered multiple vendors, looking at equipment quality and reliability. The V31 came highly recommended by our sales rep and solutions engineer, Angelic Amancio of Pacific Packaging and Inspection, and Mettler-Toledo’s great customer service sealed the deal.”

TricorBraun, St. Louis, recently announced it entered into an agreement to acquire Sandy Springs, Ga.-based Veritiv Containers, previously known as All American Containers. Veritiv is a national distributor of both custom and stock rigid packaging solutions for the food and beverage industry, operating facilities across North America. “This acquisition further enhances our North American footprint, offering customers expanded solutions and supply chain options,” said Court Carruthers, TricorBraun’s president, in a statement. “The Veritiv team is highly respected for their expertise, focus on quality and customer service, and we are pleased to welcome them to the TricorBraun family.”

Distributor of maintenance, repair and operation replacement parts and technology solutions Motion Industries Inc., Birmingham, Ala.,entered an agreement to purchase the Blairsville, Pa.-based International Conveyor and Rubber (ICR). The transaction was set to close at the end of December 2024. ICR services commercial and industrial customers in the eastern United States, the company says. ICR also provides engineering and design services for custom solutions, serving a variety of industries.

Trelleborg Sealing Solutions, Stuttgart, Germany, recently named Adam Li as global segment manager, food, beverage and water. In this new role, Li will be responsible for collaborating with internal teams to provide food, beverage and water customers focused resources and services for their applications, the company notes. “As food, beverage and water applications are characterized by very challenging sealing requirements, our seals and materials must comply with many different local, regional and global specifications and regulations,” said Carsten Stehle, global director of strategic business development, in a statement. “Our global setup and size differentiate us from other players in the market. Adam will be instrumental in managing these aspects of the segment.”

The Paperboard Packaging Council (PPC), Springfield, Mass., unveiled its 2024-2025 Board of Directors, which it describes as “a dynamic group of industry leaders dedicated to shaping the future of the paperboard packaging industry.” The group is comprised of accomplished professionals with a breadth of expertise and forward-thinking visions. Together, the group will “steer PPC’s mission to advance innovation, champion sustainability and strengthen the industry’s workforce,” it says. At the forefront is PPC’s Executive Committee. The committee is chaired by Stephen Scherger of Graphic Packaging International.