Supplier's

Marketplace

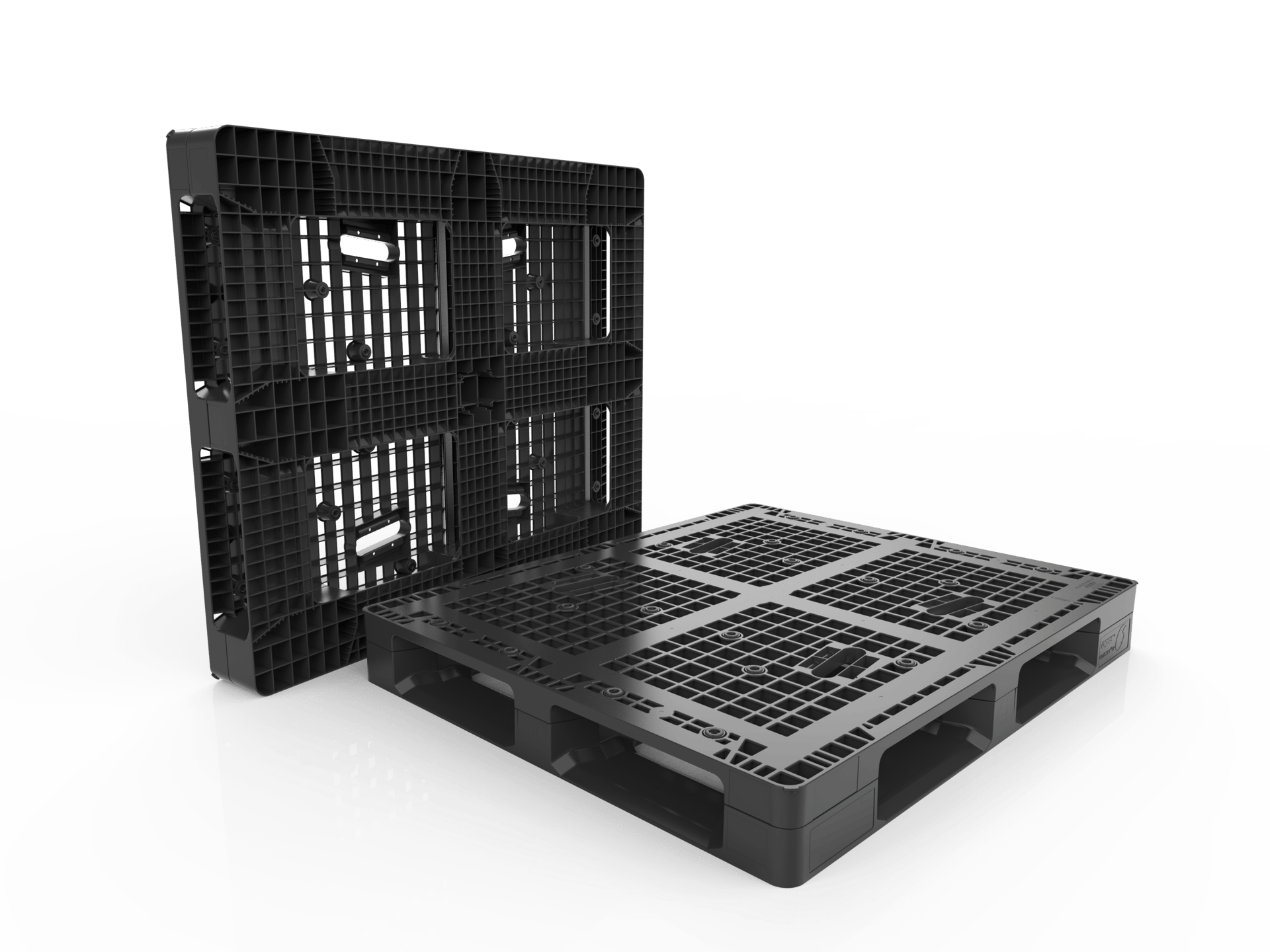

Low-profile pallet latest from ORBIS Corp.

Material handling experts ORBIS Corp. added a new pallet to its portfolio of reusable plastic pallet offerings: a 40-inch-by-48-inch Odyssey Low Profile (LP). Designed to provide repeatable performance with automated equipment, the pallet is dimensionally consistent and robust, the company says. It boasts the same stability and unique features of the original 40-inch-by-48-inch Odyssey pallet, but with a low-profile height of 5.6 inches, it notes. With this new height, the company hopes it will be an added benefit to seamlessly integrate with alternate pallets in existing pallet pools. “The efficient handling of palletized product in automated systems is key to building an effective, economical and sustainable supply chain,” said Alison Zitzke, senior product manager, in a statement. “In designing the new low-profile version of the Odyssey pallet, we wanted to keep the superior benefits of the original design while also providing our customers a lower profile height to fit more product in a truck, reduce transportation costs and provide consistent pallet performance in automated systems.” With smooth plastic surfaces, the pallet protects product loads and can be used in a variety of applications — and it can be fully recycled at the end of its life through the Recycle with ORBIS program.

ORBIS Corp.

1055 Corporate Center Drive, Oconomowoc, Wis. 53066; 800/890-7292; www.orbiscorporation.com

New Dual Shaft Mixer from ROSS

Industrial mixing, blending, drying and dispersion equipment producers ROSS recently introduced a new line of Dual Shaft Mixers. The robust and versatile system of mixers can batch dispersions, suspensions and emulsions with viscosities up to several hundred thousand centipoise, the company says. The ROSS FDA-3500 is custom-built, with a maximum working capacity of 3,500 gallons and a two-zone stainless steel dimpled jacket for heating and cooling, it notes. It also boasts a 4-inch pneumatic discharge valve and an explosion-proof load cell system, which is rated for as much as 20,000 pounds, it says. Equipped with independently controlled drives, the multi-agitator system is highly efficient in producing both good turnover and imparting shear to a vicious batch, it adds. It’s powered by a 300 HP TEFC inverter duty motor, with the high speed disperser running at top speeds as fast as 5,000 feet a minute. The speed induces high shear forces, while the 60 HP Three-Wing Helical Anchor Agitator feeds product toward the disperser blade, ensuring that the mixture is constantly in motion, it says. The anchor has Teflon scrapers that wipe materials from the walls of the vessel, which enhances the heat transfer from the mixer’s jacket.

Charles Ross & Son Co.

710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-ROSS; www.mixers.com

Peterbilt presents advanced truck technology

At the Consumer Electronics Show (CES) in January, Peterbilt showcased its battery-electric and autonomous vehicles in the PACCAR booth. Peterbilt’s Model 579EV delivers a zero-emission performance and has a battery-electric drive system with a range of 150 miles, the company notes. The system can be recharged in as little as three hours. Peterbilt’s Model 579 also was on display at CES. The model is equipped with the L4 advanced autonomous Aurora Driver from Aurora Innovation. The sensor suite features high-resolution custom cameras with nearly 360-degree field of view, FirstLight lidar that can track and measure the velocity of moving objects 8.5 seconds faster than traditional lidar, and imaging radar that provides full coverage in challenging weather conditions, the company says. Peterbilt is a leader in the commercial EV industry, with the widest lineup of electric vehicles, it adds. The three configurations are available for regional haul, pickup and delivery, and refuse applications. The company provides services and support for those looking to add EVs to their fleets, with a team to help identify the best configuration, locate available incentives and choose from the wide selection of PACCAR chargers and solutions, it notes.

Peterbilt

1700 Woodbrook St., Denton, Texas 76205; 940/591-4000; www.peterbilt.com

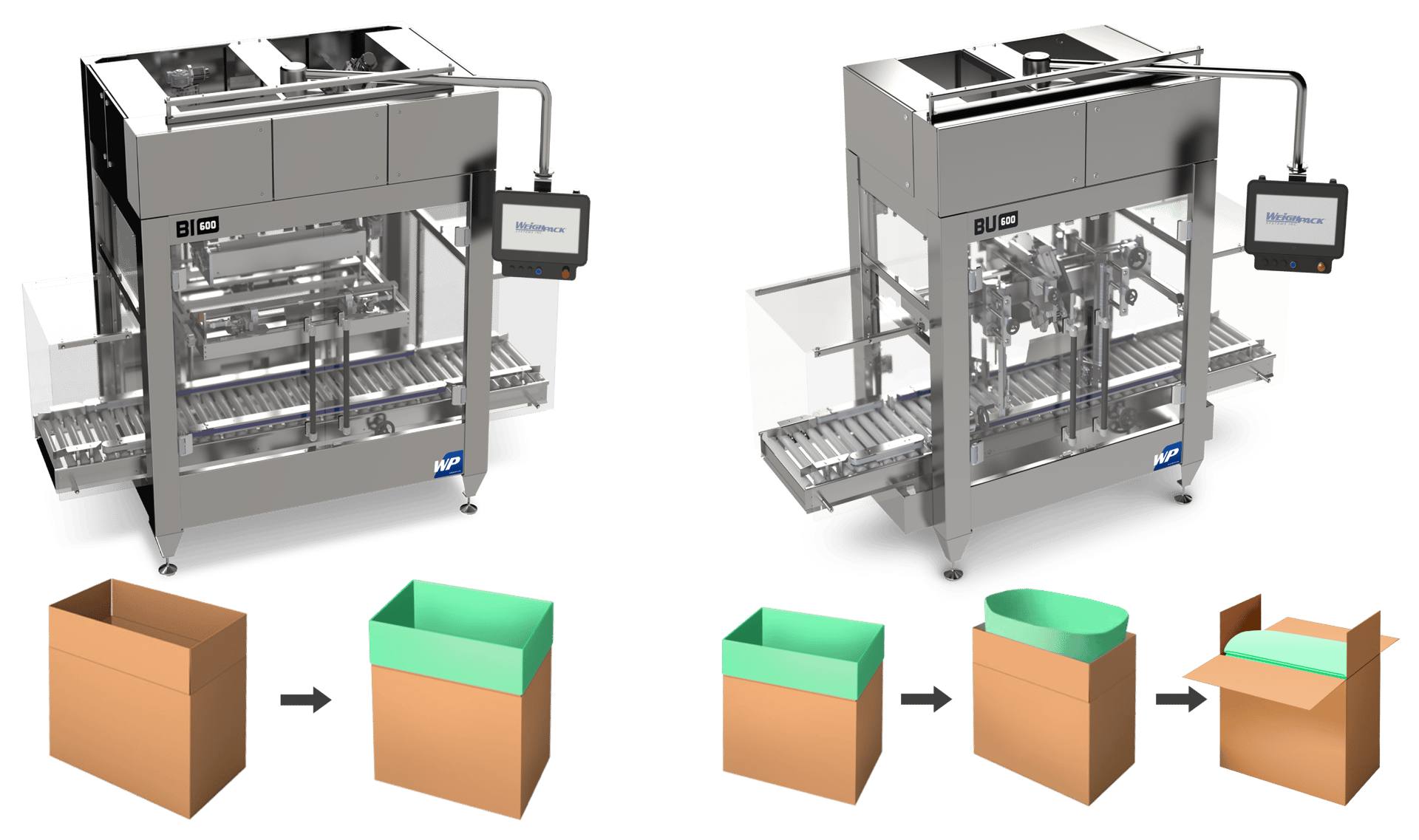

Bulk bagging made easy with inserter and uncuffer from WeighPack

Two state-of-the-art packaging machines were just released by WeighPack: the BI 600 and the BU 600. The machines were designed to automate the bulk bagging process, with the BI 600 being an automatic bag inserter and the BU 600 being an automatic bag uncuffer. The two are a replacement for the manual insertion of bags into cases and the manual uncuffing and sealing of those bags prior to case closure, the company says. The BI 600 and BU 600 are ideal for preparing bulk quantities of products for shipping, it notes. The system is designed to seamlessly fit in a bulk bag filling line, with the capability to form, fill and seal cases, trays and bins and the bulk-sized bags within them, it says. With the bag inserter, film is dispensed on a roll, cut, sealed then inserted into an erected case. After the product is weighed and filled, the case is passed onto the bag uncuffer, where it is uncuffed from the case, folded over the product and conveyed to the next packaging phase. WeighPack says it can customize a complete bulk bagging system to meet weighing, filling, case erecting and case sealing needs.

WeighPack Systems Inc.

5605 Rue Cypihot, Saint-Laurent, QC H4S 1R3, Canada; 514/422-0808; www.weighpack.com

TechniBlend’s ProFill V is versatile, valuable and volumetrically accurate

Beverage processing company TechniBlend recently launched the ProFill V, its new volumetric can filler. Aimed to advance the industry into a new level of production capabilities, the filler allows for organizations to fill their cans with a predetermined quantity of a liquid, the company notes. This technology replaces the traditional filling approach of sensory technology that relies on measuring by weight or height, it says. Running at speeds between 100 and 600 plus cans a minute, the ProFill V achieves consistent filling volumes in various can sizes for a variety of beverages and liquids. The machines can be built to fit the needs of the individual organization. Benefits of the ProFill include versatility, value and volumetric accuracy, the company says. The series uses an electronic HMI interface for recipe-based changeovers and filler operation that is simple and repeatable, ensuring a shortened changeover time and more production capability, it notes. The stainless steel can handling and change parts allow for easier cleaning, quick changeover and super smooth can transport in and out of the filler and steamer, it says.

TechniBlend

21800 Doral Road, Milwaukee, Wis. 53186; 262/484-4090; www.techniblend.com

Nonprofit trade association RadTech,the association for ultraviolet and electron beam (UV+EB) technologies, announced that Michael Gould of Rahn USA Corp., has earned a two-year term for the group’s presidency. The term started in January of this year. Mike Bonner of Saint Clair Systems Inc. has been elected to assume office as incoming RadTech president in 2025. RadTech also welcomed a variety of newly elected board members and bid farewell to those rotating off the board. Board members will attend the RadTech annual meeting and biennial Big Ideas Conference and Exhibition in San Diego next month.

A new and improved website recently was launched by Texas-based Rocket Rack. The website has new features to increase functionality and improve user experience, with one of the newest additions being the integrated online product catalog, the company says. The catalog allows the customer to browse and interact with the company’s complete line of products, view images, descriptions, dimensions, standards and technical information for each part, it adds. “Our team has been hard at work designing a website that is unique, informational and easy to navigate, while still giving users the ability to fully discover the innovation and simplicity of the Rocket Rack platform,” said Stephanie Ellis, director of marketing at Robroy Industries, in a statement.

Conveyor and equipment manufacturer and distributor Dorner appointed a new regional sales manager: Jon Doughty. In this new role, Doughty will cover the Northeast portion of the United States for the company, working with channel partners and key accounts to grow the company’s automation and sanitary conveyor business in the region. With more than 25 years of material handling experience, Doughty has served positions in sales, engineering and project management. “I’m very excited about the opportunity to join a world-class organization like Dorner,” he said in a statement. “Dorner has an unparalleled reputation throughout the industries it serves and I’m looking forward to working with our customers and channel network throughout the Northeast.”

Fleet Advantage announced the retirement of its CEO, John Flynn. President and Chief Financial Officer Brian Holland will take his place as part of a long-standing succession plan. Flynn’s career in trucking and transportation spans more than 40 years, having founded his first startup in the 1980s that focused on a lease program using tax-leveraged lease financing. Fleet Advantage says he organized the company and added to their services with environmental stewardship. “John has been a legend in the industry,” Holland said in a statement. “He’s helped Fleet Advantage earn the respect of both transportation and equipment finance industries, and his bold nature has been exactly what our nation has needed to constantly push the envelope to develop a cleaner, more modern truck transport system.”

After 49 years in the industry, John Hrdlick announced his retirement from INX International Ink Co. Hrdlick’s retirement as president and CEO will go into effect April 30. Bryce Kristo will then be promoted to serve as the new president and CEO of the North American ink company. Kristo was promoted to executive vice president in 2018 when Hrdlick was elevated to the title of president and CEO. “I am honored that SAKATA INX and INX have trusted me to serve as president and CEO, especially since I followed Rick Clendenning,” Hrdlick said in a statement. “He was a strong force and leader in our company for many years.” Hrdlick added that the “core reason for the success” of the company was due to his many dedicated coworkers.

February 2023 | bevindustry.com