Supplier's

Marketplace

Multi-Conveyor reveals varying sanitation levels conveyor

Manufacturer of pre-engineered standard and specially designed conveyor solutions, Multi-Conveyor, revealed its latest innovation: a food-grade transport conveyor system. The new system consists of two levels of sanitary compliance, made of stainless steel initial conveyors that are constructed for maximum 3A Dairy compliance. It is designed with both high levels of sanitary washdown and subsequent lower sanitation levels, per the customer’s request, the company notes. The design fills bags, which travel through a sectional wall and into a reduced sanitation area. Using guideless conveyance to transport the bags, only the contact with the belt delivers the bags to their next destination. To assist in the combining of two timed release lanes, the design features a 90-degree bag transfer and backstop area, which also assists in changing bag orientation. Multi-Conveyor notes that the backstop “helps guide the flexible package wide-edge leading from the transfer onto the transport sections” and 90-degree curves to the case packer. A table top conveyor feeds another case packer and conforms to the floor plan line layout required by the customer.

Multi-Conveyor LLC

P.O. Box 10, Winneconne, Wis. 54986; 800/236-7960; www.multi-conveyor.com

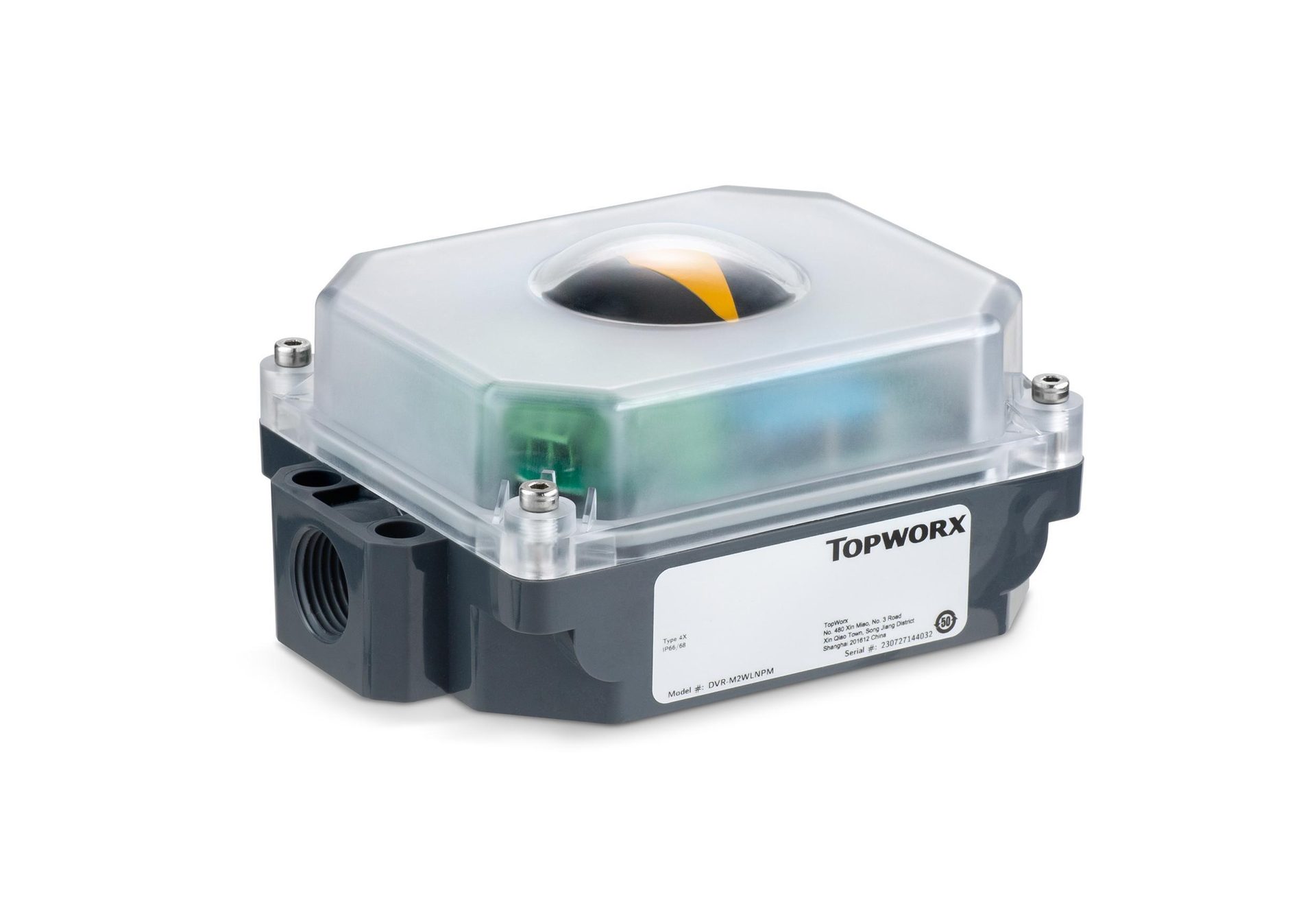

Compact valve position indicator latest from Emerson

Global technology and engineering company Emerson recently launched a compact valve position indicator. The indicator, called the TopWorx DVR Switchbox, is an entry-level addition to the DV Series of valve position indicators, and is engineered for quick and easy commissioning, the company says. Combining a durable resin enclosure, compact size and a patented cam design, it provides food and beverage production lines with a reliable valve position feedback tool, it adds. The Switchbox uses a low-profile indication, which provides easy-to-read local position feedback. The data retrieved is in real-time and can help technicians and plant operators keep processes on target, the company notes. With stainless-steel components, the Switchbox is engineered for harsh environments and provides a reliable, corrosion-resistant valve indication solution that keeps customer processes running smoothly. The feedback of valve positioning is both clear and highly reliable, helping process industry plants, platforms and pipelines operate with peak efficiency and safety, without taking up additional production line footprint, the company says. The cam design allows for swift position configuration for faster, easier installation and maintenance, and is well-suited for confined spaces, it notes. Additionally, the enclosure has an ultraviolet (UV) F1 rating, providing UV resistance that ensures the DVR performs reliably over long-term outdoor conditions.

Emerson Automation Solutions

8000 West Florissant Ave., P.O. Box 4100, St. Louis, Mo. 63136; 314/553-2000; www.emerson.com

Doran Manufacturing launches new 360 tire monitoring system

Tire monitoring system manufacturer Doran Manufacturing launched Doran YardCheck 360 to help fleets “rein in tire-related costs and stop problems before they can impact production,” the company says. The system continuously monitors tire pressure and temperatures, even if the equipment is powered off, it notes. For example, if a monitored tire within YardCheck 360’s wireless coverage zone has low pressure, a rapid deflation event or high temperature, fleet managers will be notified, it says. The data helps prevent equipment downtime and reduces operating costs through scheduling repairs and corrections. The company notes the system, with its visibility, also helps extend tread life, protect casings and improve fleet safety. The YardCheck 360 Gate Reader creates a wireless coverage zone at a facility, and inside that zone, external, valve stem mounted sensors pass tire pressure and temperature data to a rechargeable, battery-powered transceiver on each asset. The data is received by the YardCheck 360 Gate Reader and uploaded to the cloud every 15 minutes, automatically. The data is transferred for equipment that is powered on and once a day for equipment that is powered off. Both current and historical tire pressure and temperature data are visible online, and customers have the option to set up alerts.

Doran Manufacturing

4362 Glendale Milford Road, Cincinnati, Ohio 45242; 866/816-7233; www.doranmfg.com

DashTrack revolutionizes restaurant management

DashTrack is offering a cost-effective, streamlined one-stop solution for restaurant management through an all-encompassing platform. With this platform, DashTrack provides restaurant clients with customization that allows them to manage the many functions of their business, while also maximizing their digital presence to help grow their brands, the company says. “Our goal is to help our clients’ businesses thrive by allowing them to effortlessly manage their concepts with just a single login,” said Founder and CTO Jordan Hudgens in a statement. “We’ve simplified the complexities of overseeing multiple concepts and locations and seamlessly integrated multiple features and functionalities of restaurant management into one easy-to-use platform.” Developed with the range of the hospitality industry in mind, DashTrack is designed to offer four core modules to provide clients with a comprehensive and complete digital ecosystem, it says. “We want to be more than a service,” Hudgens added. “We want to be an effective partner that helps our clients scale their growth and achieve success through the ease of technology.”

DashTrack

6803 East Main St., Scottsdale, Ariz. 85251; 877/528-6278; www.dashtrack.com

New brakes from Force Control eliminate costs, downtime

Force Control Industries, a leader in oil shear technology, unveiled its new MagnaShear motor brakes. The brakes are maintenance-free and require no adjustment, virtually eliminating motor brake downtime and maintenance costs, the company says. The resulting increase in production time can bolster productivity, efficiency and profitability for manufacturing plants, it adds. The dependable motor brakes allow maintenance personnel to be tasked with other projects, allowing facilities to accomplish more work with fewer employees, the company notes. MagnaShear motor brakes employ oil shear technology, allowing for a longer service life in demanding applications, such as those with frequent start/stop cycles or where the motor is reversed each cycle. Oil shear technology transmits torque between lubricated surfaces, and thereby eliminates wear on friction surfaces, the company explains. The MagnaShear brakes are totally enclosed, making them impervious to moisture, dirt and dust that is common in many manufacturing and warehouse environments. With the oil shear technology, a smooth, “cushioned” stop is achieved, reducing shock to the drive system, and again, extending service life of downstream components, it says.

Force Control Industries Inc.

3660 Dixie Highway, Fairfield, Ohio 45015; 513/868-0900; www.forcecontrol.com

Artificial intelligence (AI) technology company Nala Robotics announced Massimo Noja De Marco as chairman to its strategic advisory board. The company is working to revolutionize the culinary industry, and De Marco has established ties with both major and emerging brands, it says. “Nala Robotics welcomes Massimo as chairman to our strategic advisory board,” said founder and CEO Ajay Sunkara in a statement. “His wealth of knowledge, expertise in automation, robotics and AI, as well as his global connections and business acumen, will prove immeasurable to lead our advisory board as we execute on the next phase of our growth strategy.”

Premium Label & Packaging Solutions (PLPS) unveiled Chris Payne as CEO and Leslie Gurland as vice president of sales and marketing. Together, the pair are “working to harness the technical expertise and unique capabilities of the company’s eight locations and transition them to operate as one company under the PLPS brand,” the company says. “Having known or followed the original founders throughout my career, I’m thrilled to join the PLPS team,” Gurland said in a statement. “Our slogan is ‘Changing the Packaging Paradigm,’ and we are extremely focused on delivering just that. We are committed to maintaining the passion, creativity and responsiveness customers want while continuing to grow the company in size and unique offerings.”

Global provider of product and service solutions RS recently added five new suppliers: Techflex, ProSoft Technology, Testo, NOSHOK and EXAIR. These additional suppliers will further augment RS’ selection of connectivity, test and measurement, and compressed air solutions to be used in industrial applications, the company notes. Techflex engineers and manufacturers braided sleeving products; ProSoft designs and manufactures industrial connectivity solutions; Testo works on portable test and measurement instrumentation and solutions; and NOSHOK is a supplier of measurement solutions. Finally, EXAIR engineers and manufactures compressed-air-operated products.

Fleet Advantage released results from its latest industry benchmark survey. The company took the pulse of industry leaders on a range of topics, from equipment utilization to preferred financing methods. “It continues to be clear that business agility, financial flexibility and a strategic eye toward future fuel options remain front and center for companies with transportation fleets and for-hire fleets,” said Brian Antonellis, CTP, senior vice president of fleet operations at Fleet Advantage, in a statement. The majority of respondents (59%) indicated they are operating their trucks five years or less before replacement, which continues to support today’s greater focus on shortening asset lifecycles, the survey shows. In the current survey, 33.3% indicate interest in electric vehicles during the next five to seven years (29.6% saying another 10 years), and 38.5% indicating hydrogen.

DrinkPAK, a manufacturer of premium alcohol and non-alcohol beverages, is investing more than $450 million in two state-of-the-art manufacturing facilities in the Dallas-Fort Worth (DFW) area of Texas. “We are thrilled to expand our advanced manufacturing organization with two new state-of-the-art facilities that will enable us to manufacture more high-quality drinks for the best brand sin the world,” said CEO Nate Patena in a statement. “This expansion positions DrinkPAK at the forefront of innovation in the beverage industry, offering unique opportunities for the creation of canned low-acid products.”