Supplier's

Marketplace

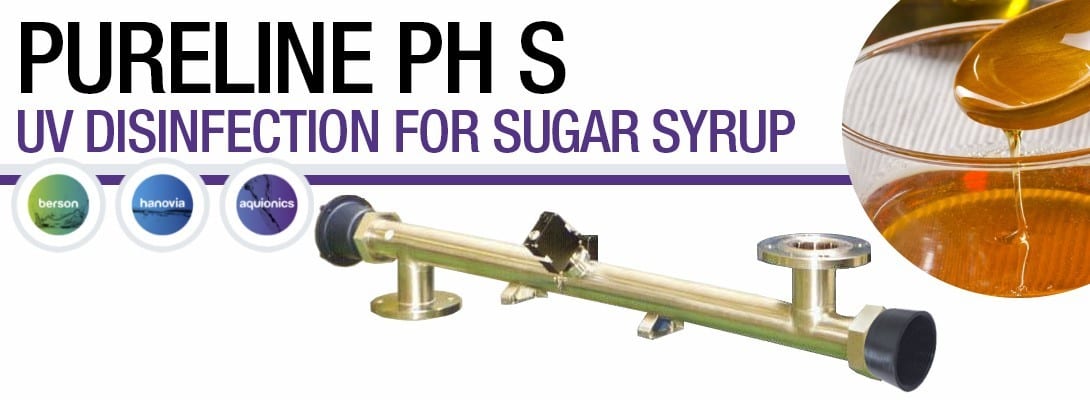

Aquionics’ UV treatment

Aquionics Inc. announced a new UV innovation, which provides a viable solution for eliminating heat-resistant molds and thermotolerant organisms in sweetener solutions. Designed to eliminate beverage spoilage organisms such as Lactobacillus, Alicyclobacillus and heat resistant molds (HRMs) that survive pasteurization, the newly designed inline UV treatment is directly installed into existing piping or recirculated on sucrose storage tanks. Beverage producers can leverage this technology to extend product shelf life, eliminate off flavors and odors, and ensure product consistency from batch-to-batch, the company says. Traditionally, UV technology had been limited with sweetener solutions because UV light does not penetrate these formulations as easily as applications commonly seen in ingredient water treatment. However, Aquionics’ UV innovation utilizes a slender vessel design coupled with hydraulics to vigorously mix the product inside of the chamber, it states. This allows the sweetener solution to come into closer contact with the high intensity UV system lamps, thereby disinfecting difficult-to-inactivate microorganisms. The technology also can withstand the higher temperatures commonly seen in sugar syrup applications, up to 176 degrees Fahrenheit whereas older technologies were limited to a maximum operating temperature of 104 degrees Fahrenheit, it notes.

Aquionics Inc.

1455 Jamike Ave., Suite 100, Erlanger, Ky. 41018; 859/341-0710; www.weuvcare.com.

JBT-Avure Technologies

1830 Airport Exchange Blvd., Suite 160, Erlanger, Ky. 41018; 614/255-6633; avure-hpp-foods.com.

JBT-Avure FlexiBulk

JBT-Avure Technologies unveiled the FlexiBulk, a fast, bulk high-pressure processing (HPP) machine. The company notes that the FlexiBulk can fill a 55-gallon bag in one minute. Unlike other HPP machines, the patent-pending FlexiBulk HPPs individually packages food and beverage products and bulk products simultaneously, the company says. The reason the FlexiBulk works so efficiently is because filling is done outside the HPP press, enabling the equipment to fill bags, in baskets, while other bags are being pressed and unfilled. Additionally, the FlexiBulk processes multiple eco-friendly options, such as cans and glass bottles, which normally are not available to HPP. The increased capacity of 90% for liquid bulk fills improves packing density, resulting in better throughput, according to the company.

GP PRO

133 Peachtree St., Atlanta, Ga. 30303; 404/652-4000; www.gppro.com.

GP PRO Automated Beverage Sealer

GP PRO, a division of Georgia-Pacific LLC, introduced a new dispensing solution for foodservice patrons: the GP PRO Automated Sealer. Helpful for on-premise dining, the machine includes a self-service attachment, which transforms it into a front-of-house solution that lets patrons quickly and conveniently seal their own beverages, freeing staff to focus on food preparation and customer service. The Automated Sealing Machine is a touchless beverage lidding solution that provides a tamper-evident, spill-resistant sealed film on to-go cups and helps improve hygiene, reduce accidental spills and eliminate the need for plastic snap lids. Originally launched as a back-of-house solution in the early days of COVID-19, the resurgence of on-premise dining led GP PRO to develop a patron self-service solution that helps drive fountain beverage sales, provides customers with greater convenience and a commitment to health and safety, according to Alec Frisch, vice president and general manager of GP PRO’s foodservice category.

ABB, Zume automate production of 100% compostable packaging

ABB Robots and Zume partnered to automate production and provide a cost-effective alternative to single-use plastics. ABB Robots also will enable the scale and speed required to make Zume’s packaging from 100% compostable packaging made from plant-based agricultural materials, the companies say. Data from the United Nations Environment Program (UNEP) states that less than 10%, or 380 million tons, of plastic produced globally every year is recycled. ABB will supply robotic cells that will enable Zume’s production of sustainable packaging on a global scale and will integrate and install more than 1,000 molded fiber manufacturing cells (MFC) and send as many as 2,000 robots to Zume customer’s sites worldwide during the next five years, the company says. ABB will leverage its program management capabilities and automation experts in its network of Global Solution Centers to enable the scale, modularity and speed required to launch the solutions, which have the potential to annually produce millions of pieces of sustainable packaging. Containers are molded from the plant material by Zume’s molded fiber cells integrated with two ABB IRB 6700 robots, with each cell processing up to two tons of agriculture material every day, creating 80,000 pieces of sustainable packaging.

ABB Robotics

1250 Brown Road, Auburn Hills, Mich. 48326; 248/391-9000; www.zume.com/zume-x-abb.

INX International natural-based inks

INX International Inc. released a new, natural-based ink system — INXhrc RC — designed to help brand owners and printers meet their sustainability goals when printing on rigid plastic and foam-based packaging. The high-performance ink system features clean, renewable and sustainable ingredients, the company says. Additionally, the UV and LED curable inks are Nestle compliant and designed for printing on non-porous, rigid plastic and decorative plastic as well as foam-based packaging, it adds. INXhrc RC represents the next chapter of the successful INXhrc natural-based inks that were launched in 2017. Through 2020, INXhrc water, solvent and conventional offset inks have replaced nearly 5 million pounds of petro-based chemicals, waxes and additives, and almost 13 million pounds of carbon emissions, it adds. Earlier this year, INX reached an agreement with packaging manufacturer HAVI to use INXhrc as one of the constituent materials for food paper packaging. INXhrc RC is a step in the company’s plan to develop renewable technologies for brand owners and printers, with minimal impact on the environment and reduced regulatory risks. The non-allergenic inks are formulated without VOC solvents and contain high levels of bio-renewable content.

INX International Ink Co.

150 N. Martingale Road, Suite 700, Schaumburg, Ill. 60173; 800/631-7956; www.inxinternational.com.

Former WestRock President and CEO Steven C. Voorhees accepted the Lifetime Achievement Award at Paperboard Packaging Council’s (PPC) fall meeting. The Robert T. Gair Award for lifetime achievement pays homage to a man who paved the way for the modern paperboard packaging industry. The award recognizes exemplary individuals who have demonstrated a lifetime of significant and lasting contributions to the industry. Under Voorhees’ leadership, WestRock, created as a result of the merger between Rock-Tenn and MeadWestvaco in 2015, succeeded in many areas, the company notes. Voorhees was instrumental in expanding the company’s geographic presence facilitating 20 acquisitions during his tenure as CEO. As chief financial officer from 2000 until 2013, the company grew from $1.4 billion in sales to $10 billion. He was named CEO in 2013, and his efforts and leadership ultimately helped WestRock secure its status as the second largest packaging company in the United States, it adds.

Clean Energy Fuels Corp., Newport Beach, Calif., broke ground on a renewable natural gas (RNG) digester at Del Rio Dairy in Friona, Texas, its first in a joint venture with TotalEnergies to produce the ultra-clean transportation fuel, which will be negative carbon intensive. All the RNG fuel produced at the dairy will make its way into Clean Energy’s nationwide network of RNG stations. When completed, the Del Rio Dairy digester project will capture the waste from more than 7,500 milking cows and generate an anticipated 1.1 million gallons of RNG annually. Clean Energy has a target to provide RNG at all its U.S. stations and for the carbon intensity of the fuel to be zero by 2025.

The Aluminum Stewardship Initiative (ASI), a nonprofit that establishes independent third-party certification for the aluminum value chain, announced that Crown Holdings Inc., Yardley, Pa., has met its standards for responsible production, sourcing and stewardship of aluminum with a focus on material stewardship. The ASI Performance Standard certification for Crown’s Brazil operations advances the company’s progress within its Twentyby30 sustainability program and supports its customers in their own responsible sourcing goals.

Raleigh, N.C.-based Tompkins Solutions named Roy Smith as vice president of sales of its material handling integration division. In this role, Smith will be responsible for driving sales revenue and growth by building and maintaining customer relationships and delivering best-in-breed material handling integration solutions. He has more than 35 years of sales management and logistics engineering experience, designing and supplying more than $100 million of material handling solutions for companies across a wide variety of industries. His extensive systems expertise includes, but is not limited to, automated storage and retrieval systems (ASRS), automated guided vehicles (AGVs), conveyors, robotics and other warehouse automation solutions.

Lancaster, Pa.-based Graham Packaging announced that its Evansville, Ind., location has received its International Sustainability and Carbon Certificate (ISCC) PLUS. This certification enables the site to sell customers ISCC PLUS certified post-consumer resin (PCR) created through advanced recycling. The certification, from SCS Global Services, an international leader in third-party certification, validation and verification for environmental, sustainability and food safety, will help Graham meet its long-term goal of incorporating an average of 20% PCR across all bottles by 2025, it says. The company plans to earn ISCC certification for additional facilities across its global locations in the future.

Milwaukee-based Arbon Equipment Corp., a wholly owned subsidiary of Rite-Hite, has acquired Pugleasa Co. Inc., a loading dock and industrial door sales and service organization headquartered in Arden Hills, Minn. In the material handling business for 65 years, Pugleasa has been the exclusive distributor of Rite-Hite products in Minnesota, the Dakotas and parts of western Wisconsin and northern Iowa since the mid 1980s. The new office is part of a growing network of Arbon Equipment sales and service providers with more than 65 offices in the United States, Canada and Australia.