Supplier's

Marketplace

KHS Innopack Kisters Carton Nature Packer

The KHS Group released its Innopack Kisters Carton Nature Packer (CNP). Among the benefits are its ability to process can toppers made of cardboard at a rate as fast as 108,000 cans an hour. With the help of its recently developed CNP machine, the turnkey supplier is establishing an environmentally friendly alternative to plastic in the secondary packaging market. Based on proven technology, the modular design gives customers greater flexibility with a packaging system that is customizable, the company says. Additionally, operators can switch to different cardboard materials or alter the pack size, among other options. The company is noticing that packaging variants are being established as alternatives to single-use plastic, especially in the beer and carbonated soft drink segments, it says. In partnership with Smurfit Kappa, one of the biggest manufacturers of cardboard worldwide, KHS offers cardboard can toppers in two styles: a closed (TopClip) and open (GreenClip) version. The future-proof packaging system is sustainable, consumer friendly and gentle on resources. The cardboard packer also can be used for standard and sleek can formats with can sizes of between 250 and 580 ml. The alternative to classic plastic film or plastic rings also manages various sizes of multipacks containing four, six or eight containers. Another point-of-sale benefit is that adhesive is not used during processing; the pack is kept stable by the punched and folded cardboard topper. As an added option, the CNP machine also can be equipped with a camera-controlled orientation module to enable cans to be precisely positioned within the pack. This gives beverage producers and retailers a number of clear benefits from a product marketing perspective. For instance, the cardboard topper heightens the product’s presence at the point of sale and provides extra space for advertising messages, the company says.

KHS Group

Juchostraße 20, 44143 Dortmund, Germany; +011/49-231-569-0; www.khs.com.

Sidel StarLITE HPC Base

The Sidel Group introduced its StarLITE HPC base solution, which is designed to increase the stability of flat PET and rPET containers by up to 25%. The new, oval bottle base alternative for flat PET containers helps achieve optimum performance and also can comply with recycled PET (rPET) up to 100%, the company says. The new bottle base not only increases container stability by as much as 25%, but also optimizes bottle weight and energy consumption, reducing production costs and greenhouse gas emissions with a quick payback. The anti-rocking, asymmetric design is based on a 360-degree continuous contact surface to improve tilt angle, and can be combined with structural ribs and oval push-up. “The doubled sitting surface and the balanced stretching ratios between small and large sides enable better material distribution, while avoiding base sagging,” explains Laurent Naveau, a packaging expert at Sidel. The oval shape provides an optimum performance level, drastically improving empty or filled container stability by as much as 25% and increases production uptime due to better container stability on conveyors, it adds. The more sustainable and cost-effective base solution is applicable for opaque and transparent PET resins. The following are other benefits of the solution: improves material distribution; prevents unexpected base roll-out; contributes to lightweighting opportunities; and improves base cooling during blow molding. The StarLITE HPC is compatible with all generations of Sidel blow molding machines: SBO EvoBLOW, SBO Universal, SBO Series2 and SBO Series1.

Sidel Group

5600 Sun Court, Norcross, Ga., 30092; 678/221-3087; www.sidel.com.

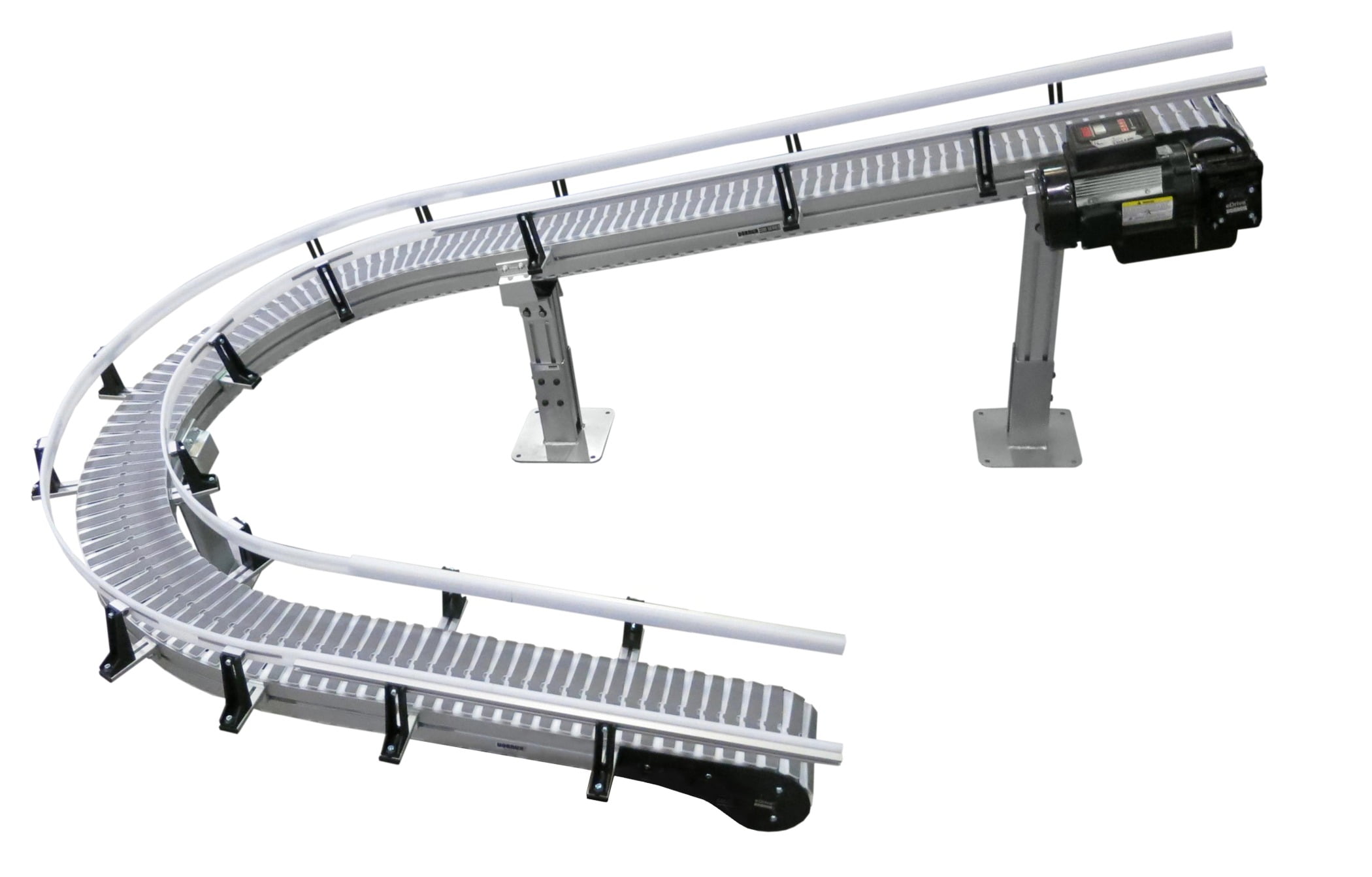

FlexMove Helical Plain Bend Conveyor

For applications that require conveyor flexibility with a smaller footprint to save floor space, Dorner unveiled its FlexMove Helical Plain Bend Conveyor. The FlexMove conveyor provides customers with unlimited configurations, including flat to flat; flat to incline; incline to flat; and incline to incline. These configurations, which also include inclines and declines through corners and straights, provide flexibility for applications involving product buffering especially in corners, the company says. The conveyors are outfitted with a patented side roller chain to reduce corner friction. With a load capacity of 300 pounds and a maximum speed of 180 feet a minute, the FlexMove Conveyors are available in bearing chain and non-bearing chain models with corner angles of 45-, 90-, 135-, 180-, 225-, 270- and 360-degrees. Additionally, the friction chain is recommended for incline and decline angles of 7 to 12 degrees, while the plain chain model is capable of incline/declines angles of up to seven degrees.

Dorner

975 Cottonwood Ave., P.O. Box 20, Hartland, Wis. 53029; info@dorner.com; 800/397-8664; www.dornerconveyors.com.

Dynatrol CL‐10GH Liquid Level Detector

The Dynatrol Division of Automation Products Inc. unveiled its newest liquid level detector: Dynatrol CL-10GH. Designed for lasting performance in beverage processing, the Dyntarol CL-10GH is used for high-, mid- or low-level point detection in the beverage industry, the company says. Applications can include fructose, corn syrup or sugar liquor. The new detector is designed for more stability because it utilizes the Dynatrol EC-501A(G) control unit to eliminate the variances of direct input power. The detector requires no field adjustments and is easy to install in almost any position in a vessel or pipe. It provides rugged construction with a sensitive transmission of vibration energy. If needed, corrosion-resistant coatings are available. The explosion-proof CL-10GH has a pressure rating of 3,000 psig at 100 degrees Fahrenheit with high temperature construction of 300 degrees Fahrenheit available. The new model is available with a 4-24mA DC proportional output and has no floats, diaphragms, packing glands or moving parts.

Automation Products Inc.

Dynatrol Division, 3030 Maxroy St., Houston, Texas 77008; 800/231-2062; www.dynatrolusa.com.

Baldwin FlexoCleanerBrush, FlexoDry2

At the ConneXion virtual expo June 1-8, Baldwin Technology Co. Inc. showcased key innovative technologies for optimized corrugated high-graphics package printing. During the event, visitors got a firsthand look at fully automated Flexo plate-cleaning systems, an energy-efficient IR (infrared) drying solution and LED-UV curing systems, all of which increase print quality and productivity, with operator safety and sustainability in mind. The FlexoCleanerBrush is the company’s flagship solution to enhance print quality and improve worker safety in corrugated printing. It automatically removes dust and contamination from the plate in seconds during production, without stopping the press, and it produces virtually no waste, it says. The FlexoDry2 is a fully integrated IR drying system, specifically developed for corrugated Flexo printing presses, that reduces energy consumption by as much as 30% over standard IR dryers through the use of patented Diamond IR lamps. The system provides enhanced color definition, reducing or eliminating marking altogether, allowing for high-speed and full-confidence printing. Lastly, the company highlighted its next-generation LED-UV technology for wide-format Flexo corrugated box printing. It provides a 50% reduction in power consumption in an ultra-compact lamp head that fits at the end of the press or between printing units. Flexo inks, coatings and varnishes specifically formulated to cure when exposed to LED-UV light can provide a high-value decorative solution for brand owners, offering offset-like quality and vibrant color, as well as full-gloss, spot and matte coating effects on a wide range of corrugated stocks, with the added ability to enhance lower-cost papers.

Baldwin Technology Co. Inc.

8040 Forsyth Blvd., St. Louis, Mo. 63105; 314/863-6640; www.baldwintech.com.

In its 2020 Annual Report, Imola, Italy-based SACMI reported sales of more than $1.3 billion and a stable net equity of $832 million. Throughout the year, the group was committed to ensuring workplace safety and continuity of production and assistance. Investment in product innovation and a new in-company “digital culture” continued. The number of employees remained steady at almost 4,600 and the company retained its technological leadership, it says. SACMI President Paolo Mongardi said: “In this incredibly hard year, SACMI demonstrated just how prepared it is to face such challenges. The first step was to safeguard the health of every worker, making it possible to ensure continuity of both production and assistance in Italy and worldwide. We achieved thanks to the responsibility, passion and skill of all our people and handled via an immediate nurturing, at every level, of a new digital culture.”

The Association for Advancing Automation (A3), Ann Arbor, Mich., announced that its Autonomous Mobile Robots & Logistics Conference will take place in-person Oct. 12-14 in Memphis, Tenn. FedEx has been named the official Title Sponsor and will provide select conference attendees with a behind-the-scenes look at some of its Memphis-area innovation and operations facilities. The conference and tradeshow will focus on the surging interest in mobile robotics, distribution, material handling and eCommerce technologies. Registration is now open. For information on speaking, exhibiting, sponsoring or attending, contact A3 at events@automate.org or call 734/929-3268.

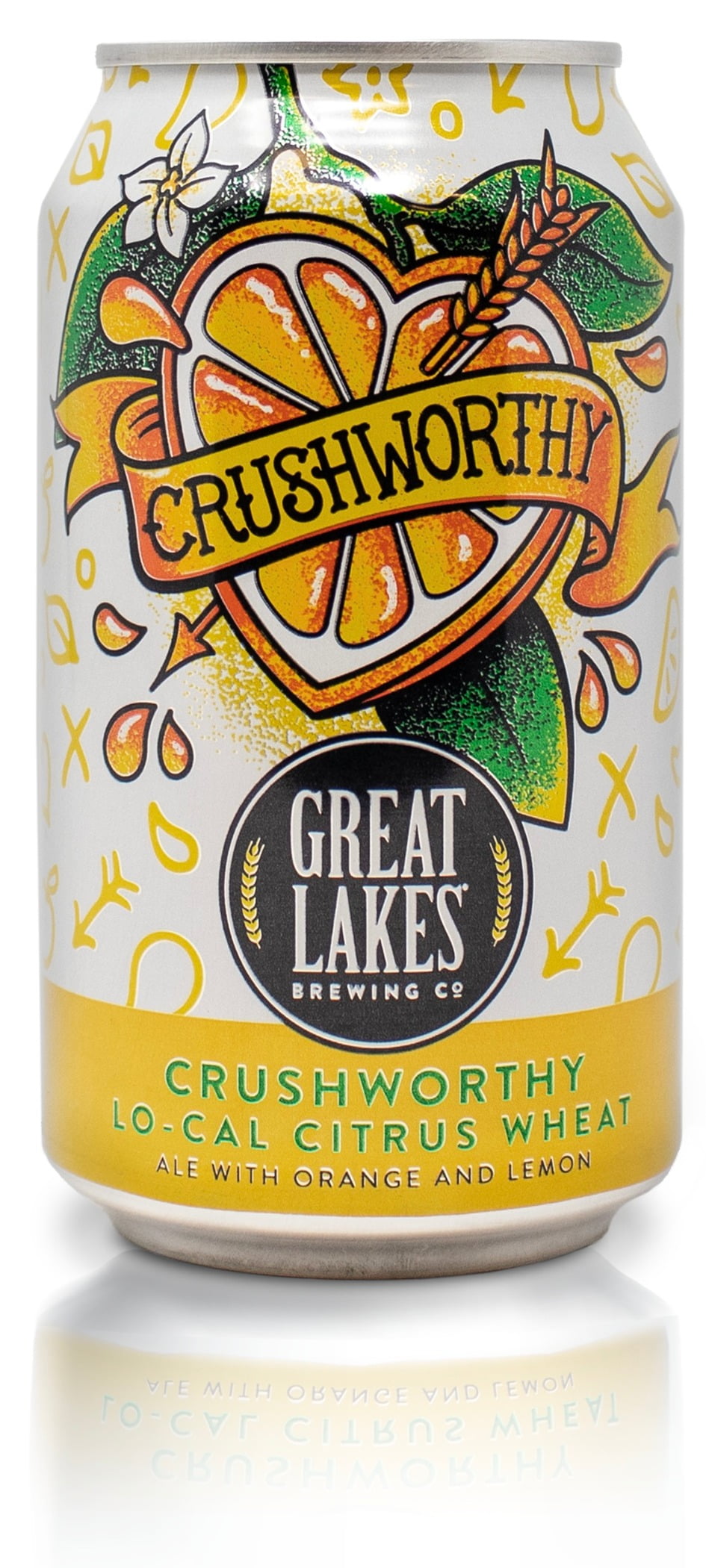

INX International Ink Co., Schaumburg, Ill., reports that Great Lakes Brewing Co. took first place in INX’s second annual Colored by INX Can Design Contest. The Cleveland-based microbrewery and brewpub garnered 35% of the votes with their Crushworthy Lo-Cal Citrus Wheat entry. Great Lakes won with 264 votes, 80 more than runner-up Jacki O’s Brewery, Athens, Ohio. Other finalists were Brewery Ommegang, Cooperstown, N.Y., Duvernois Creative Spirits, Montreal, Quebec, and Wis-Pak, Watertown, Wis. Contest entries were created by designers who used the INX Metal Color Catalog and required the use of at least two colors from the INX Color Perfection library.

A new survey by GlobalTranx, a provider of logistic technologies for shipping companies, and Edelman, a data and communications firm, finds that most U.S. supply chain organizations are optimistic about their business performance in 2021, with 91% believing last year’s problems are behind them. The survey, published in April 2021, involved more than 200 supply chain leaders and managers contacted in March who have more than 500 employees. The survey found that seven in 10 respondents think the COVID-19 vaccine rollout will stimulate business; 94% think there will be a robust economic recovery in 2021, again due to the vaccine rollout; and 60% think the recently passed stimulus package will have a long-term positive impact on the economy, supply chain operations and business revenue.

Woodridge, Ill.-based Hendrickson launched a Dealer Sales Academy as a complement to its already popular Hendrickson Service Academy in the company’s continuing effort to expand its “Innovation Built In” philosophy while remaining customer focused. The new Sales Academy is comprised of videos, assessments and related resources to help dealer salespeople understand the features, benefits and specifications of Hendrickson products so their customers can make the optimum ride solution choice. The Hendrickson Sales Academy now is available online at www.sales-academy.hendrickson-intl.com.

ABB’s NEMA motor division announced it is investing $1 million in a Peak Innovation Center in Fort Smith, Ark. The investment will be dedicated to the acquisition of state-of-the-art equipment for the Advanced Manufacturing program and its Automation/Robotics, Electronics Technology and Computer Integrated Machining pathways program. The Peak Innovation Center is a regional partnership between Fort Smith Public Schools and the University of Arkansas – Fort Smith. It will open in August, and will be available to approximately 43,000 total students from 22 regional school districts.

July 2021 | bevindustry.com