Supplier’s Marketplace

Masterpack Group shares benefits of bulk bag gassing

Modified Atmosphere Packaging Technology is the way to go for bulk packaging, according to Masterpack Group. Bulk packaging includes FIBC, big bags, super sacks and tote bins. This type of packaging technology is growing each year to strengthen the supply chain by both protecting and improving product quality and safety, the company says, as well as ensure better storage and transportation of the packaged material and reducing overall product waste. Many products in the dairy and food industries have short shelf lives or are easily ruined or spoiled when they are exposed to oxygen and moisture. M-A-P FIBC Big Bags and Big Liners utilize a liner that keeps product safe from oxygen, moisture and insect or pest contamination without the use of chemicals or gasses, the company explains. The modified atmosphere technique does not use chemicals or pesticides, and is achieved by adjusting oxygen levels to less than 1% via deep-vacuum, and then gas flushing with either nitrogen or carbon dioxide within the packaging to the desired value, the company notes. Nothing is added to the product, which ensures freshness and safety. The company’s MAP technology allows for ease when conducting unintrusive manual or automatic sampling and data collection of the atmosphere inside the material packaged inside, giving a fully documented chain of custody data, it says.

Masterpack Group USA

82 South White Horse Pike No. 100, Berlin, N.J. 08009; 215/987-9665; www.masterpackgroup.com

Multi-Conveyor creates coffee pod conveyor

Multi-Conveyor recently built a series of conveyors to elevate and transport or redirect individual coffee pods. The key was to elevate the odd-shaped pods to the height required to feed a metered scale ahead, the company says. Filled and sealed single-serve plastic cups of coffee initially enter a stainless-steel bulk infeed hopper. The coffee pods are then elevated nearly 11 feet on minimal 1.5-inch tall flights, or cleats, that provide necessary stability of the irregular shape of the product. The incline of the system is 8 inches wide with flights on 5.4-inch centers, moving on practical flat top 900 series belting by Intralox, Multi-Conveyor shares. “Our engineers are masterful at choosing just the right practical belting that provides maximum benefit,” the company said in a statement. The pods are then transported on a 4-foot section to the metered scale. If the counter or scale reach capacity, a stainless-steel, three-sided pneumatic actuated pivoting discharge chute with cover was incorporated to redirect overflow product into a super stack to keep production flowing and moving at all times. Underside guarding is included to ensure operator safety, the company notes. Also included in the design are snap-on bearing covers, clear polycarbonate top covers and expanded metal bottom safety pans.

Multi-Conveyor LLC

P.O. Box 10, Winneconne, Wis. 54986; 800/236-7960; www.multi-conveyor.com

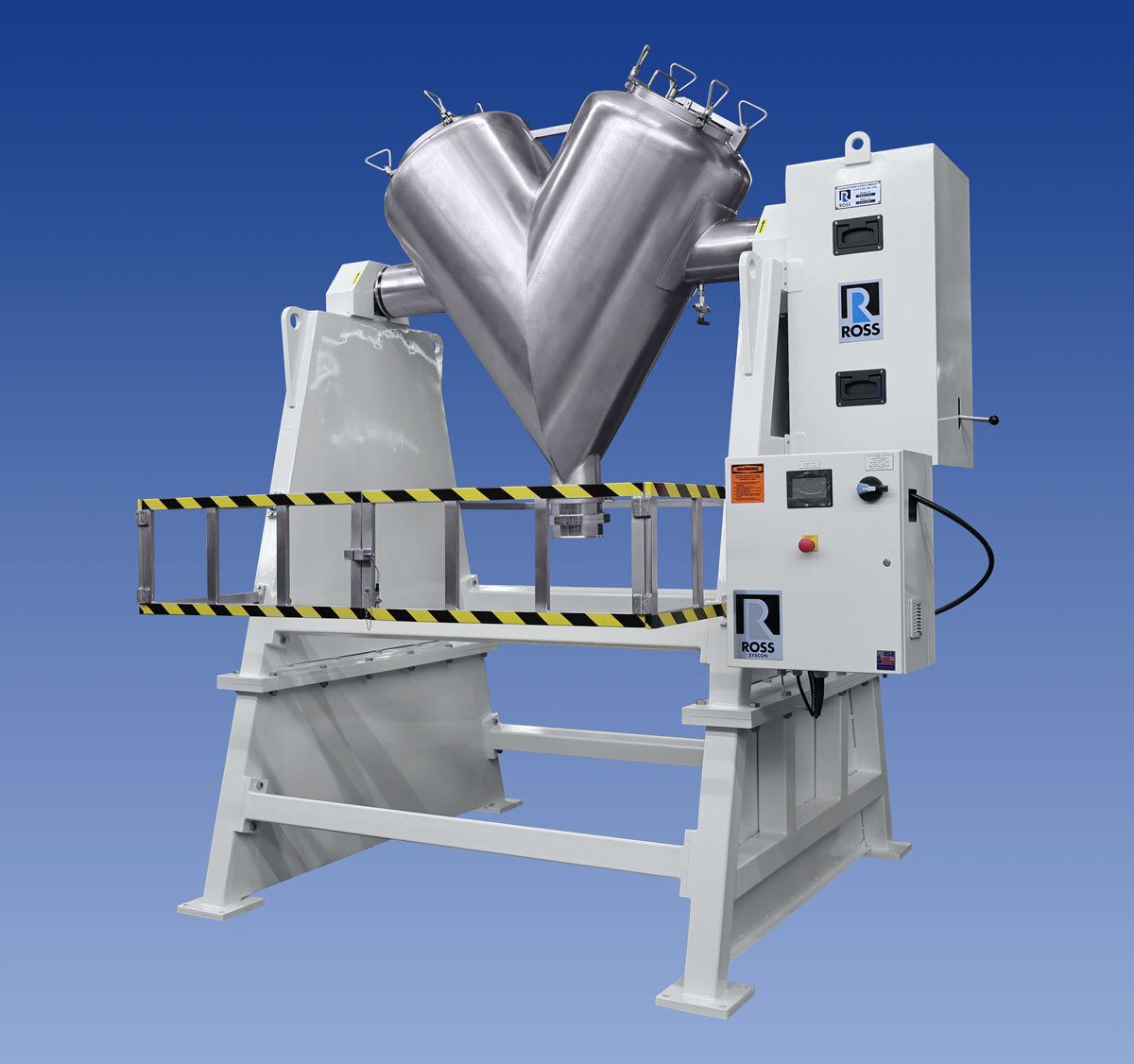

New ROSS blender offer precise mixes of free-flowing solids

The latest blender from ROSS was engineered for applications that require gentle, yet thorough mixing. The ROSS V-Cone Blenders are used across numerous industries where consistency is essential, the company notes. The blenders rotate a V-shaped vessel along its horizontal axis, creating a cascading action that continuously exposes and redistributes materials, it says. The low impact tumbling motion is good for friable ingredients, trace components or materials with significant differences in particle size and density, it adds. The new purpose-built ROSS Model VCB-10 blender was constructed with stainless steel product contact surfaces, featuring a 10 cubic foot working capacity. It supports a maximum bulk density rating of 125-pounds per square foot. ROSS is offering designs for higher densities as well. The vessel rotation is powered by a 7.5 HP TEFC motor, which can achieve speeds up to approximately 20 rpm. A safety rail assembly prevents unintended contact with the blender’s rotating assembly, with a two-section front gate equipped with a limit switch and safety interlock switches and a fixed rear guard rail. A manually operated 8-inch stainless tell type 304 dust-tight butterfly valve provides efficient discharge, with support legs providing a 54-inch clearance beneath the valve to the floor. The NEMA 12 Control Panel includes a 4-inch color touch screen interface for viewing and controlling blender operations, a cycle timer, jog function and an emergency stop pushbutton, the company notes. The control system is pre-mounted and wired to the blender for streamlined installation and startup.

Charles Ross & Son Co.

710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-ROSS; www.mixers.com

Collaborative palletizing solution latest from AMT

FANUC Level V Authorized System Integrator Applied Manufacturing Technologies (AMT) has introduced a plug-and-play collaborative palletizing solution built around the FANUC CRX-30iA robot. The new system is designed to solve common labor, safety and productivity challenges with fast deployment, intuitive operation and minimal floor space requirements, AMT says. The cobot palletizing solution was built for flexibility and ease of use, allowing manufacturers to increase throughput, reduce ergonomic risks and maintain uptime, even with lean staffing, it adds. Unlike off-the-shelf systems, AMT states that its solution features a custom-developed user interface (UI) that simplifies setup and empowers end users to create and modify palletizing patterns independently. “Ease of use was our top priority,” said Ben Kurth, director of engineering at AMT, in a statement. “Users can quickly input case dimensions, select a pallet pattern and begin operation: no coding or specialized training needed. That flexibility is a game changer for dynamic production environments.” The FANUC CRX-30iA is an industrial-grade robot designed for continuous operation in demanding environments, the company says. As a power- and force-limited cobot, it can safely work in close proximity to people without the need for fencing, freeing up valuable floor space and eliminating the costs and complexity of traditional industrial robot cells, it notes. “Cobot technology finally gives manufacturers a way to automate palletizing in places where industrial robots simply won’t fit,” Kurth added. “This system is ideal for high-mix, low-volume production or facilities with tight space constraints.” Key advantages of this new system include collaborative safety, custom configuration, operator independence, space efficiency and operator independence.

Applied Manufacturing Technologies

219 Kay Industrial Drive, Orion, Mich. 48359; 248/409-2000; www.appliedmfg.com

Industrial automation system integrator Hargrove Controls & Automation, a subsidiary of global EPC firm Hargrove Engineers & Constructors, announced that Tim Shope has joined the team as controls and automation pulp and paper industry leader. Leading efforts to strengthen and expand the company’s presence and offerings, Shope brings a range of experience to Hargrove. “I’m thrilled to lead the Hargrove automation team in an industry that has been a cornerstone of my career,” he said in a statement. “I look forward to applying my experience to help our clients develop operational and economic solutions that focus on future operational excellence.”

E Tech Group revealed it acquired JSat Automation (JSat). JSat is a system integrator specializing in automation, IT/OT convergence and compliance. JSat will operate under the new name JSat an E Tech Group Co. JSat is the third acquisition for E Tech since 2023. “We’re excited to welcome JSat to the E Tech Group,” said Matt Wise, E Tech Group CEO, in a statement. “E Tech Group life sciences clients will benefit from a highly talented team with industry expertise, which includes manufacturing execution systems, lab automation, informatics and robotics. JSat’s international offices bring E Tech’s global reach to 10 countries, enabling us to serve our clients in all their locations around the globe.”

Distributor of maintenance, repair and operation replacement parts Motion Industries Inc. unveiled its first Canadian Motion Conveyance Solutions shop. The new facility, located in Calgary, Alberta, was designed to enhance Motion’s ability to serve customers’ growing needs across Western Canada. The 9,600-square-foot facility joins a network of more than 40 Motion Conveyance Solutions shops across the United States and further expands the company’s service footprint, with state-of-the-art belting technology.

Mettler-Toledo announced its “Test Before You Invest” product inspection program. The program is designed to help manufacturers “make informed product inspection choices through hands-on testing, real performance data and expert support,” the company says. Manufacturers can send in product samples to the Mettler-Toledo facility in Lutz, Fla., for detailed testing under controlled conditions. Each test concludes with a detailed, tailored report compiled by Mettler-Toledo product inspection specialists.

Sustainable flexible packaging solutions provider Accredo Packaging recently shared the appointment of Frank Winter as chief financial officer. In this new role, Winter will lead the financial strategy and operations for both Accredo and its parent company, API Group, with his more than 25 years of financial leadership experience. “Frank brings a powerful blend of financial rigor, strategic insight and industry expertise,” Rex Varn, chief operating officer of API Group, said in a statement. “As we continue our rapid growth, his leadership will help us scale responsibly, make smarter investment decisions and build a finance function that is both agile and deeply aligned with the business.”