Supplier's

Marketplace

Emerson smart valve positioner

Emersonunveiled the TopWorx PD Series Smart Valve Positioner. The fluid control and pneumatics technology company has an expansive portfolio of TopWorx sensing and control products. Using communication through a 4-20 mA loop signal and HART protocols, the PD Series provides 100% control over valve positioning. This technology allows customers to extract valuable feedback while monitoring for trends that offer predictive maintenance insights to help prevent costly downtime, the company says. The PD Series utilizes Hall effect contactless position detection, which increases product reliability, the company says. It was designed to withstand an array of environmental conditions. “Every facility, no matter its environment, needs to be sure it’s operating as safely and efficiently as possible,” said Paul Bristow, Emerson’s global product manager, in a statement. “That’s why the PD Series was designed for trusted performance in demanding conditions in many different applications and industries.” The PD Series will launch with two models: the PD100 for general purpose applications, and the PD200 for use in explosive atmospheres. The series is built to the same industry-leading standards, as proven by other TopWorx products, which are built to “deliver exceptional value and trusted performance for demanding application,” it says. The PD Series is fitting for applications in an array of industries, such as oil and gas, chemical, industrial energy, and food and beverage.

Tetra Pak fiber-based carton

Tetra Pak recently completed a 15-month commercial technology validation of a polymer-based barrier replacing aluminum in food carton packages. The company is moving forward with another development: a fiber-based barrier to replace the aluminum barrier. This technology would reduce the company’s carbon footprint and make the post-consumer products more appealing for recyclers, it says. Tetra Pak reported that, although the aluminum layer in food packages is thinner than a human hair, it contributes to a third of the greenhouse gas emissions linked to base materials used by the company. In collaboration with some customers, Tetra Pak currently is testing the new fiber-based barrier, with a pilot batch of single serve packs with this material on the shelf for commercial consumer testing. Further technology validation is scheduled for later this year. “Early results suggest that the package with a fiber-based barrier will offer substantial CO2 reduction when compared to traditional aseptic cartons, together with comparable shelf life and food protection properties,” Gilles Tisserand, the company’s vice president of climate and biodiversity, said in a statement. “We believe the development will therefore act as a breakthrough reducing climate impact.” The initiative “marks yet another breakthrough” in Tetra Pak’s mission in developing an aseptic package that is “fully renewable, fully recyclable and carbon-neutral,” the company says.

Tetra Pak USA

101 Corporate Woods Pkwy., Vernon Hills, Ill. 60061; 847/955-6000; Tetrapak.com/us

Emerson

8000 W. Florissant Ave., P.O. Box 4100, St. Louis, Mo. 63136; 314/553-2000 emerson.com

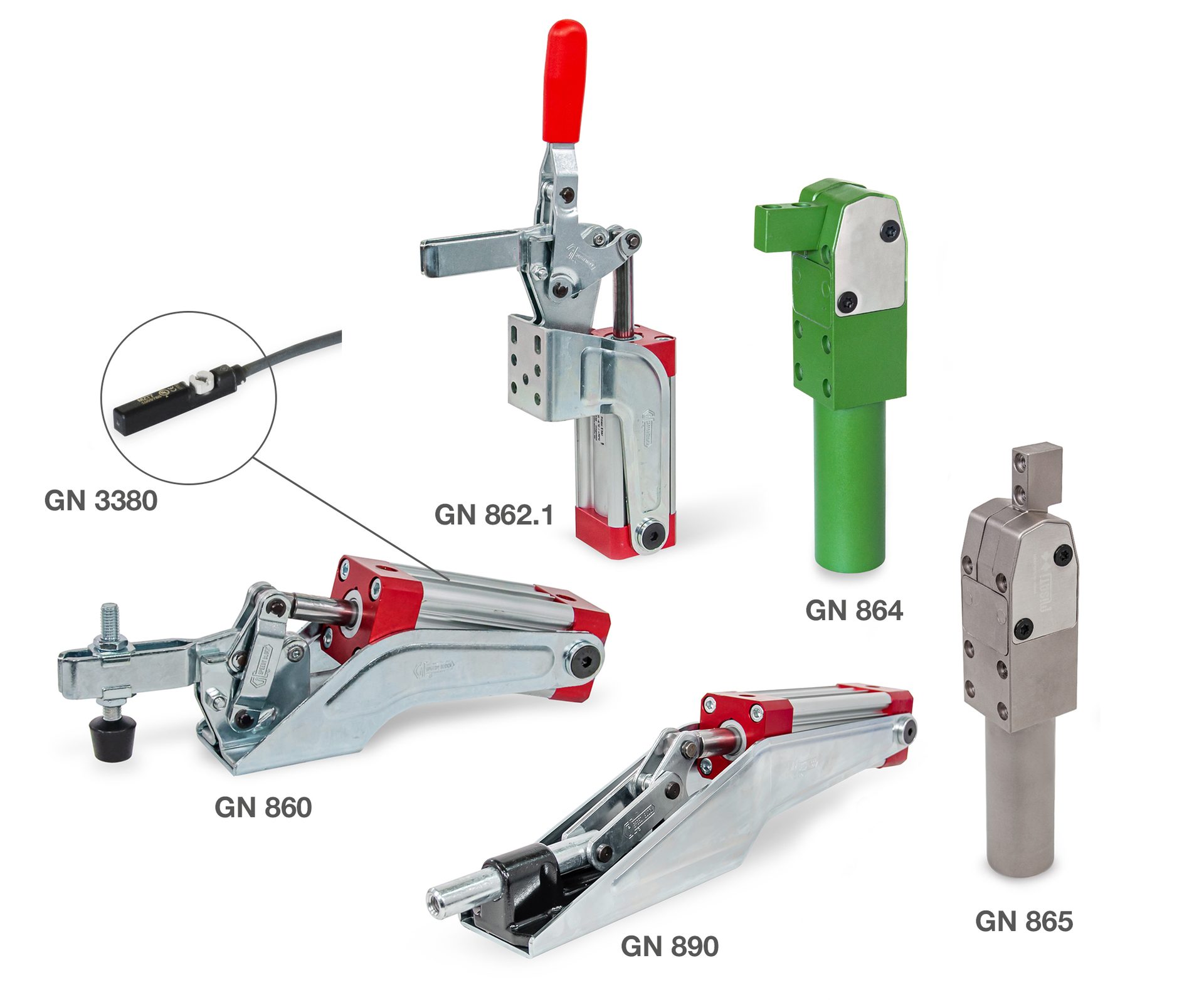

Winco updates pneumatic clamps

Winco often revises the array of parts to implement new technological features and update any changes in application requirements. The company’s pneumatic clamps received the latest update to assure a longer-lasting lifespan, as well as reliability. Of the improvements, Winco stated that the most significant improvement was with the pneumatic cylinder, which now boasts T-slots and a magnetic piston. The new slot allows for easier sensor attachment, and the magnetic piston grants “more precise querying” with the modern sensor GN 3380, according to the company. Pneumatic clamps in the GN 860 series now have “hardened, ground-bearing bushing and tempered bearing pins” for reduced wear. The updated clamps were tested for more than 250,000 cycles, with no meaningful alterations observed. Winco’s new pneumatic clamps are available in the “tried-and-true versions” for horizontal (GN 860) and vertical (GN 862). Winco also has the GN 862.1 that permits manual operation. High retaining forces, like in car manufacturing or pressing or welding lines, would benefit from the pneumatically operate power clamps of the GN 864 family, the company says. Two improvements were made to this family. One of those changes is the nickel-plated housing, which “considerably increases the corrosion resistance,” it adds. The housings were previously blackened. Additionally, the FG type is designed for welding jigs, with a green PTFE coating that prevents weld spatter from sticking, it notes.

Winco

2815 S. Calhoun Road, New Berlin, Wis. 53151; 800/877-8351; jwwinco.com

DENIOS protective charging cabinets

DENIOS Inc., a leading manufacturer of products for environmental and workplace safety, has introduced protective charging cabinets, should a lithium-ion battery, charging cord, or charger be defective. Lithium-ion batteries can sometimes combust if they get too hot, and these cabinets from DENIOS will “protect against fire hazards due to thermal runway, deep discharge, mechanical deformation or chemical reaction,” it says. The Ion-Charge 90 storage containers were designed by DENIOS specifically for this kind of battery to charge and be stored. The cabinets are manufactured with 90 minutes of fire resistance, from outside to in, and with 90 minutes of fire resistance from fires within the container reaching the outside, the company says. These units were type tested in accordance with EN 14470-1, it adds. The cabinets, which are ideal for manufacturers, dealers and distributors that incorporate Li-ion batteries into their products, come equipped with a transport base for fast and safe transportation, which is perfect should a battery be defective and the cabinet need removing, according to the company. Each unit features a triple-hinge door, easy to clean surface, charger sockets and perforated shelves.

ABB Robotics depalletizing solution

ABB Robotics recently launched a solution for difficult depalletizing tasks across a variety of industries, including consumer packaged goods. The solution involves a machine vision software that can quickly and efficiently process assorted loads. The issue of complex depalletizing is becoming more common, and often comes with manual jobs that have high turnover rates and high recruitment costs, the company says. ABB’s solution replaces the need for manual labor, utilizing an advanced machine vision and learning algorithms that allow for the robot to process pallets as tall as 2.8 meters high. With advanced vision, the robot is able to locate and lift boxes as much as 30 kg and place them on another pallet or conveyor. The system’s accuracy and speed works at a peak rate of up to 650 cycles an hour, 24 hours each day. “With the ability to depalletize boxes stacked in a variety of configurations from single and mixed pallets, ABB’s Robotic Depalletizer helps to meet this need, allowing faster and more accurate handling of a wide range of goods,” said Marc Segura, ABB’s Robotics division president, in a statement.

DENIOS Inc.

1152 Industrial Blvd., Louisville, Ky. 40219; 877/388-0187; denios-us.com

ABB Robotics

1250 Brown Road, Auburn Hills, Mich. 48185; 248/391-9000 abb.com

The Association of Plastic Recyclers (APR), North America’s leading plastics recycling authority, recently announced an updated publication of PE film guidance documents. The update is part of the Washington, D.C.-based company’s Design Guide for Plastics Recyclability. Through an extensive industry collaboration, APR measured the compatibility of PE film and flexible products with recycling, something the company considers as “vital” to keeping a clean stream of materials to recyclers from retail drop-offs. After completing protocol with a testing laboratory, companies will submit results to APR, which then reviews and approves innovations. In a statement, APR’s President and CEO Steve Alexander said that cleaner supply results in higher quality PCR “that ultimately delivers products consumers want to buy.”

Last month, global leader in enterprise labeling and artwork management solutions Loftware, Portsmouth, N.H., announced a partnership with Wood Dale Ill.-based Videojet Technologies, a global leader in marking and coding solutions. The partnership is set to “change the paradigm” for how companies automate the printing process using an all-in-one digital solution, which allows companies to “seamlessly implement, deploy, maintain, and easily scale” all labeling, marking and coding on a unified platform, the company says. “Combining Videojet’s superior performance and range of marking and coding technologies and Loftware Spectrum, will offer companies a step-change in their digital, automation journey by controlling a mix of both Videojet and other vendors’ devices,” Videojet’s President Ondrej Kruk, said in a statement.

Skokie, Ill.-based LanzaTech continues to make strides in reducing the environmental impact of packaging. Laboratory technologies at LanzaTech were able to produce MEG, or monoethylene glycol, through captured carbon emissions. MEG is a key element in PET, or polyethylene terephthalate, resin, fibers and bottles. LanzaTech’s discovery came from the help of food and beverage company Danone. In a statement, LanzaTech’s CEO, Dr. Jennifer Holmgren, said the discovery is a “breakthrough in the production of sustainable PET,” with potential to reduce environmental impact in the process of obtaining MEG and creating PET. Although production still is in the early stages, the direct production of MEG cuts out many steps required to obtain MEG, the company adds.

In an effort to protect against supply chain issues, Madison Chemical, Madison, Ind., has invested in additional infrastructure. Storage facilities, new equipment, and additional plant updates continue to meet its customer’s needs. Despite most industries facing supply chain problems, the chemical formulator company said it has maintained standard delivery schedules. “Adding some extra storage/production capacity and increasing our inventory levels have enabled us to consistently provide interpreted supply to our customers, while maintaining our industry leading lead times,” President David Goodman said in a statement. Goodman also added that the company “saw the potential” for supply chain issues early on in the pandemic, and proper action was taken to ensure Madison Chemical’s customers were protected from such disruptions.

The Daimler Truck North America (DTNA) plant in Mount Holly, N.C., recently appointed Joanna Cooper to the general manager position. “Her dedication to those she leads and her ability to rally teams around a common vision make her a great fit to oversee the Mount Holly Truck Manufacturing Plant,” said Jeff Allen, senior vice president of operations and specialty vehicles, in a statement. Cooper, a 14-year company veteran, previously worked in the role as director of production at the Mount Holly Truck Manufacturing Plant. In that position, she oversaw a team of 1,500 to reach production goals. Cooper got her start working as a production buyer at Detroit, Mich.-based Detroit Diesel Corp., eventually moving up the ladder with roles of increasing responsibility.