Supplier's

Marketplace

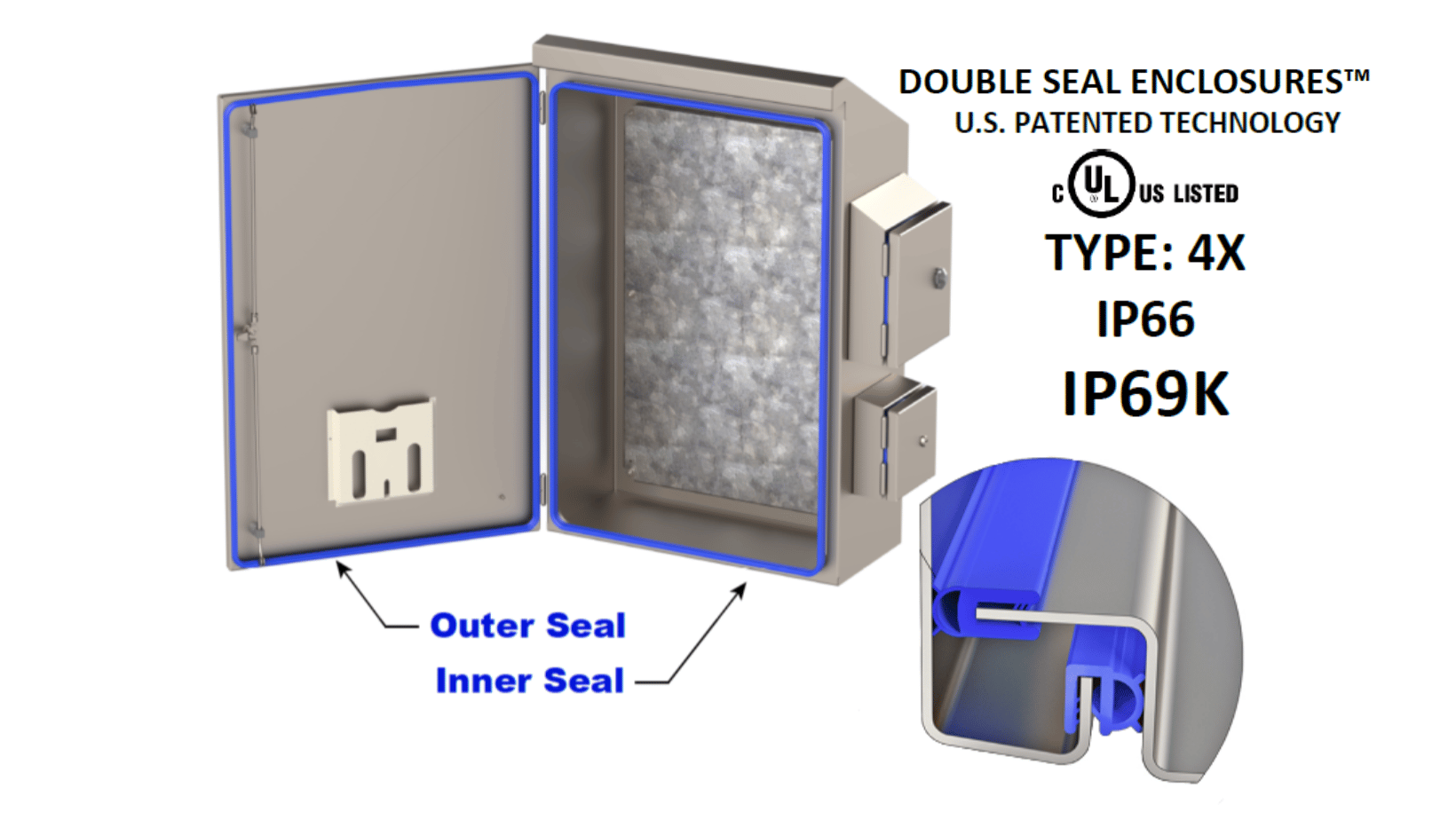

Custom Stainless Enclosures introduces “xtreme” double seal

Custom Stainless Enclosures, Inc. (CSE) is highlighting its 4Xxtreme Double Seal Enclosures for extreme indoor and outdoor environments. The enclosures feature patented Double Seal and Double Stud Mounting Technology, a design that is ultra-clean and free-draining, an award-winning “Single Hygienic Quarter Turn Door Design,” and a blue gasket system that is field replaceable. Field replacement can result in an enclosure that delivers an overall lower cost of ownership and is ideal for the food and beverage industries, the company says. This blue gasket system is made from highly chemical-resistant EPDM material, which can withstand high temperatures of 250 degrees Fahrenheit, it notes. Because the gasket material is blue, the company says the 4Xxtreme gaskets are considered Foreign Material Detectable. With multiple layers of protection, the 4Xxtreme’s outer seal rejects 99.9999% of water, ensuring that the inner seal never sees any water pressure, it says. When water does get through, the amount is minimal, and easily will pass through weep holes at the bottom of the enclosure door so that water does not build-up between the two seals, it adds. These double seal enclosures also feature award-winning “Single Hygienic Quarter Turn Door Design,” which reduces premature electrical failures, increases plant production and revenue, while also reducing the overall cost of equipment ownership, it says.

Custom Stainless Enclosures Inc.

Woodbury, Minn. 55125; 651/500-3650; www.4xxtreme.com

New flushing ring from Emerson reduces maintenance

Global technology and software company Emerson recently introduced the Rosemount 319 Flushing Ring. The ring has a valve-integrated design, which ensures accurate measurement of differential pressure and lower maintenance for a variety of differential pressure applications, the company says. The Rosemount 319 Flushing Rings are available in traditional and compact options, providing process-to-seal connection and allowing for faster diaphragm seal maintenance, it notes. Maintenance does not require disconnection from process flanges. Both versions come pre-assembled, including the flushing ring, matching valves and connections, which allow technicians to commission devices faster by eliminating the need to procure and assemble components onsite, it says. The rings are factory leak-tested, so users can mount the products to vessels straight out of the box, it adds. “Rosemount 319 Flushing Rings with integrated valve assemblies are designed to eliminate procurement and onsite labor cost,” said Nicole Meidl, Emerson’s production manager, in a statement. “Products can be commissioned faster and more efficiently, and DP level seal systems can be easily accessed for future maintenance with reduced shutdown timelines. Efficiencies like these reduce risk, cost and complexity for our customers.”

Emerson

8000 West Florissant Avenue, P.O. Box 4100, St. Louis, Mo. 63136; 314/553-2000; www.emerson.com

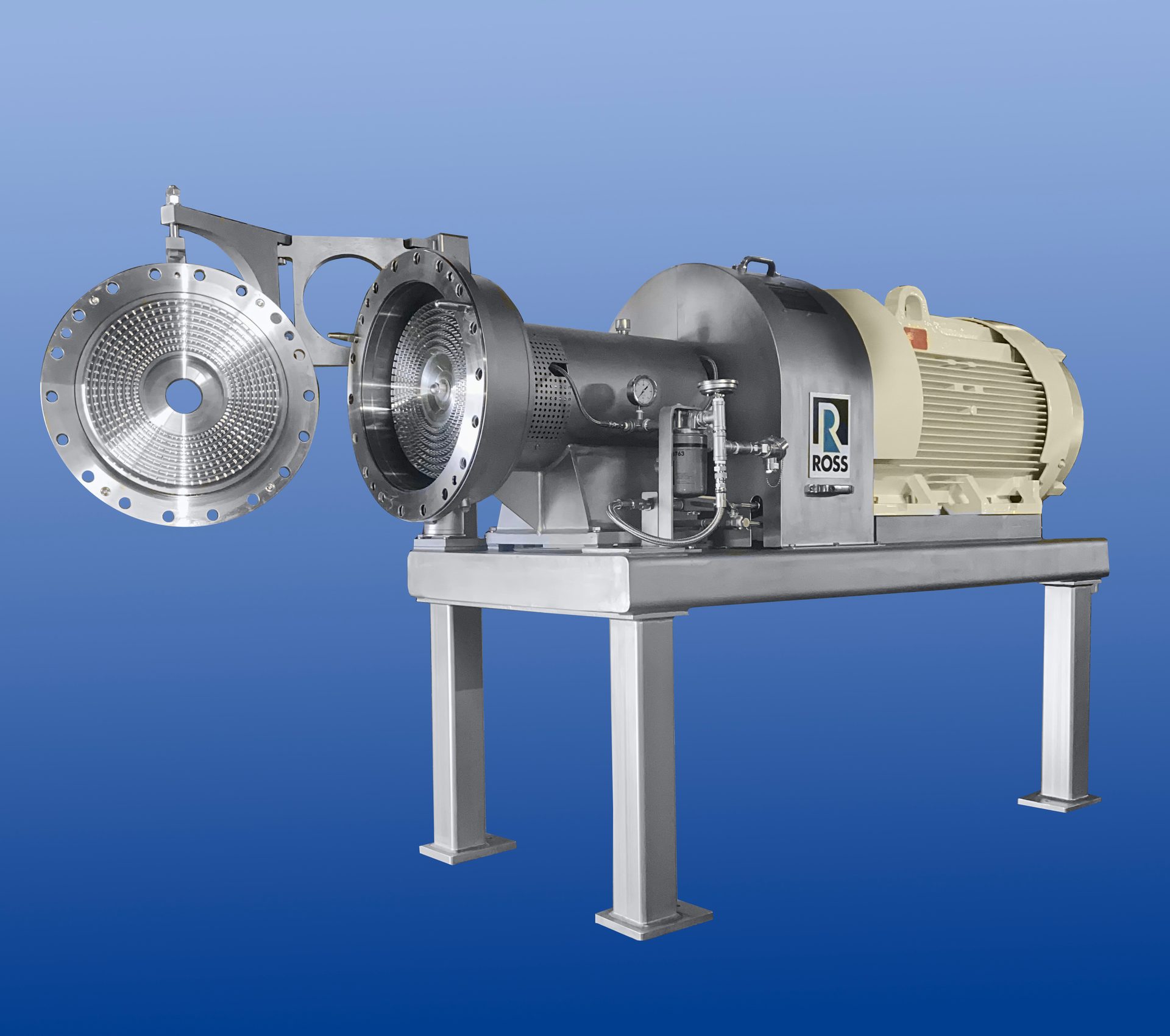

ROSS reveals Ultra High Shear Sanitary Mixer

Charles Ross & Son Co. released an Inline Ultra High Shear Sanitary Mixer Model HSM-715XSUHD-250. The mixer is designed to deliver exceptional dispersion, emulsification and homogenization at high throughput, the company says. It features the patented X-Series rotor/stator, and taking in product through the center of the stator and moving it outward through radial channels in the rows of concentric rotor/stator teeth. With the combination of high tip speed and close tolerances interlocking the channels, the product is subjected to intense shear in every pass, the company notes. The HSM-715XSUHD-250 is designed for continuous operation, driven by a 250 HP washdown duty inverter-duty motor, it says. It’s equipped with heavy-duty roller bearings, and the mixing chamber is able to withstand 150 psig at 250 degrees Fahrenheit, it adds. The mixer also has a stainless steel jacket for heating and cooling. The model is clean-in-place compliant, and the back of the mixing chamber is relieved to promote thorough cleaning around the seal. The versatile mixer is easy to clean, and is ideal for a variety of industries, including food and pharmaceuticals, it says.

Charles Ross & Son Co.

710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-ROSS; www.mixers.com

Low-profile electric actuator latest from SMAC

SMAC recently introduced an LPL 30 low-profile electric linear moving coil actuator. The actuator is designed for speed, consistency and repeatability, with ideal use in dosing and dispensing applications, the company says. “Consistency and repeatability are critical for dosing applications, especially when the quantity being dispensed needs to be exact, such as for medicines or food flavorings,” said SMAC Founder and CEO Ed Neff in a statement. “Precision also reduces waste, which saves money when the material being used is expensive, such as perfumes or pharmaceuticals.” With a 10 mm stroke and 30 mm pitch, the LPL 30 actuator’s compact size fits most dosing and dispensing machines, the company notes. The actuator is engineered for low friction as well as fast and consistence response times and force that remains steady throughout the stroke, it says. Compared with traditional air cylinders, which often have varying response times that throw off dosing volume, the LPL’s response time variation is minimal, resulting in a minimal variation in dosing volume, according to the company. These actuators have cycle rates as many as 2,400 cycles a minute — three times higher than that of air cylinders — resulting in an increased output, it says. Additionally, the actuator features SMAC’s patented “soft-land” ability, gently locating a surface, performing its function and providing real-time feedback for tracking, performance and quality control, it notes. The actuators are produced with square steel tubing at the company’s Carlsbad, Calif.-based facility.

SMAC Corporation

5807 Van Allen Way, Carlsbad, Calif. 92008; 760/929-7575; www.smac-mca.com

Yaskawa unveils simplified robotic palletizing system

The Motoman Robotics Division of Yaskawa America Inc. has expanded the capability of the Smart Pendant with an easy-to-use Pallet Builder extension. The extension facilitates the quick development and deployment of palletizing cells, and is designed for single pick and place tasks, the company notes. Utilizing a robust database and guided prompts, the system enables no-code programming for both workcell configuration and pallet pattern setup, it says. It’s ideal for small- to medium-sized enterprises with high-mix, low-to-medium volume production that might not have access to experienced robot programmers, it adds. Pallet Builder not only provides general functions for cell definition, gripper definition and single pick and place jobs, but also offers easily customizable job edits, the company notes. Supporting up to eight combined stations, there are multiple infeeds, build stations and dispenser stations. The system also can accommodate a wide variety of grippers and end-of-arm tooling, adjusting easily for various products, it says. The software includes multiple automatic pattern styles as well as custom support, while single drop positions with selectable label orientation are available, it adds. Pattern Builder is compatible with the YRC1000 and YRC1000micro controllers, and is available as a complimentary download for use with GP-series and HC-series robots.

Yaskawa America Inc.

2121 Norman Drive South, Waukegan, Ill. 60085; 800/YASKAWA; www.motoman.com

Microsoft and AU10TIX, a leader in identify verification and identity management technology, recently announced that the two would be working together on Reusable ID. The technology is a breakthrough in verifiable credentials (VC) architecture for identity management, the companies note. VCs, which are reusable and unalterable credentials, prove the identity of a person or entity, while allowing for the safe sharing of personal documents and biometric credentials. “Compliance costs, privacy concerns, data liability and rising synthetic fraud show that traditional identity management has been a struggle for individuals and organizations,” said Dan Yerushalmi, CEO at AU10TIX, in a statement. “Now, verifiable credentials are providing businesses and individuals with peace of mind regarding who holds and controls the keys of their personal data.”

North American ink producer INX International Ink Co. completed an investment agreement in Gooten. Gooten is a New York-based technology and fulfillment company. The investment is the first since INX established its $50 million INX Venture Capital investment program last year. “We see Gooten as a catalyst for enabling sustainable, on-demand manufacturing across several categories of interest for INX,” said Shane Bertsch, vice president of strategic planning and innovation at INX, in a statement. “We are eager to partner with the Gooten team to bring high quality digital printing solutions and services to our customers and partners.”

Mobile, desktop and industrial printing, labeling and safety signage solutions provider Brother Mobile Solutions announced Ravi Panjwani as president. Effective April 1, Panjwani, who joined the company in 2006, succeeds David Crist. “I am excited and humbled to lead Brother Mobile Solutions in the next chapter of the company’s journey,” Panjwani said in a statement. “We are at an innovative time in the industry, as customers are looking for smarter printing and labeling solutions that can enhance the productivity and help them overcome today’s challenges. Brother Mobile Solutions is uniquely positioned to serve as a valued partner to customers across the retail, transportation logistics, manufacturing and public safety markets.”

Last month, Brennan Industries, a supplier of hydraulic fittings, adapters and accessories, acquired SRM Industries Inc. The Houston, Texas-based company has been producing hydraulic hose protective products since 2005. The acquisition adds durability-enhancing products to the wide-ranging lineup of hydraulic fittings and accessories available from Brennan, the company notes. In a statement, Bernie Jacobsen, president of SRM industries, said he is excited for the attainment, as Brennan will be able to offer SRM products to a broader market, especially SRM’s RHINO family of products. “Many of our customers work with hydraulic hose every day,” said Dave Carr, president and CEO of Brennan, in a statement. “SRM’s products are a natural extension of our product offering and we know they will be popular with customers who are all trying to prevent leaks and extend lifetimes. RHINO Sleeve is a top notch solution and we are proud to bring it to our customers.”

Maxon Lift Corp. announced that the first 150 Tuk-A-Way GPT liftgates rolled off the assembly line at its new manufacturing plant in Monterrey, Mexico. Units have started to ship from the GPT line, while installation of infrastructure and production lines is ongoing, the company says. “As demand continues to grow in the marketplace, so will our production capabilities,” said Brent Stratton, member of the Office of the President, in a statement. “This is just the beginning of how we plan to ramp up our liftgate production to revolutionize the liftgate industry in the North American market.”

May 2023 | bevindustry.com