Packaging

Story

Beyond recycling

By Lauren Sabetta

Plastic bottling systems keep pace with sustainable packaging trends

(Image courtesy of Sidel)

Known for co-inventing the first successful self-contained underwater breathing apparatus (SCUBA), called the Aqua-Lung, oceanographer, filmmaker, author and conservationist Jacques Cousteau, is quoted for once having said, “Water and air, the two essential fluids on which all life depends, have become global garbage cans.”

Today, as industries across the globe are working toward tackling environmental degradation, the beverage industry is no different. As such, experts note that sustainable packaging efforts are having an impact on plastic bottle manufacturing.

Naima Boutroy, global packaging expert at Sidel, Octeville-sur-Mer, Normandy, points to packaging regulations coming into effect as having a great impact on promoting sustainable practices.

“For Europe, the Packaging and Packaging Waste Regulation will have a greater focus on reducing unnecessary packaging waste, with Reduce, Recycle and Reuse at the forefront,” she says. “Similarly, the Single-Use Plastic Directive (SUP), announced in 2019, states that plastic caps must remain attached to the bottle after opening on all beverage bottles 3 liters and under from July 2024 onwards. Manufacturers are currently in the process of adaptation.”

Awarded the German Packaging Prize for its extremely lightweight bottle, ShoulderFlex weighs just 5.9 grams, Krone’s Peter Igl notes. (Image courtesy of Krones AG)

As Sidel is an original equipment manufacturer (OEM), Boutroy points to company’s recent innovations and specific solutions that support beverage manufacturers’ efforts to reduce unnecessary waste, including:

- Machine intelligence with smart heating and blowing features to secure bottle quality whatever the PET resin type

- Advanced mold technologies and dedicated bottle design that enables high-quality bottles with up to 100% rPET

- Dedicated blowing process optimized for lightweight bottles while securing the best performance

- Optimized production assets through packaging lines to minimize utility consumption

- Dedicated range of line conversion services, to support the transition to tethered caps with secured productivity and fast ramp-up

Peter Igl, part of the plastics technology development team at Krones AG, Neutraubling, Germany, notes that sustainable packaging trends are mainly impacting plastic bottling in two ways.

“One is emphasizing the long present megatrend to utilize resources more efficiently, meaning both lighter packages and less energy use,” he says. “The second is the increasing usage of rPET.

“Krones recently won the German Packaging Prize for its extremely lightweight bottle (ShoulderFlex) weighing just 5.9 grams, reducing the carbon footprint of water bottles by yielding material savings up to 50% compared to conventional 0.5-liter water bottles on the market,” Igl continues.

SKU proliferation, rPET demand impacting the market

As more manufacturers look to support sustainable packaging practices, experts highlight some key beverage trends impacting the market.

Sidel’s Boutroy notes that, with demand for rPET on the rise, the market is evolving.

“rPET is proven to be the only fully circular and food-grade plastic material for the beverage and food industry at a large scale,” she says. “According to recent research, the amount of rPET used to manufacture all PET packaging in Europe was estimated at 28%.

“It’s clear that the market for rPET is evolving as more beverage and food manufacturers look to embrace a sustainable material that has no impact on manufacturing equipment,” Boutroy continues.

Krones’ Igl notes that, given high market demand for rPET, the quality of the material sometimes isn’t optimal.

“To address the worldwide trends toward sustainable packaging, beverage-makers should consider packaging manufacturing systems that help reduce their carbon footprint while also leveraging cost optimization.”

— Naima Boutroy, global packaging expert at Sidel

“rPET in general is nothing but PET from another source (recycled PET),” he explains. “But due to higher demand from the market, rPET quality and consistency is sometimes not ideal. This makes quality equipment with more inspection options more important than ever.In the end, the usage of rPET comes down to a slightly higher scrap rate, depending on the material quality.”

Among other trends impacting equipment, Igl notes that SKU proliferation has created the need for machine flexibility. “Krones offers various solutions such as LineXpress for fast line changeover or flexible logistics solutions by our Krones Group member System Logistics,” he says.

Sidel’s Boutroy, echoes similar sentiments, noting that manufacturers are looking for responsive solutions to SKU proliferation, small batches, and even on-demand for eCommerce.

“[E]quipment must be flexible and changeovers to new SKUs should secure safety, minimum downtime and fast start-up,” she explains. “Sidel engineers have designed automatized solutions to pick and choose the right production configuration while handling multiple SKUs. Ultimately changeovers are fast and easy and production efficiency is secured.”

Sidel’s range of line conversion services support the transition to tethered caps with secured productivity and fast ramp-up, Sidel’s Naima Boutroy notes. (Image courtesy of Sidel)

Krones’ Igl says that, among the most current trends impacting the market, digitalization is largely influencing bottle manufacturing.

“Our Krones Digital Services embedded in the Krones Ecosystem help our customers get the maximum out of their equipment and enable trouble-free production, with fast reaction times and superior production monitoring,” he explains. “One of the digital features especially relevant in bottle production is our Contiloop AI, an automatic monitoring and intelligent control of the blow molding process. The technology utilizes a combination of hardware and software and provides intelligent process control based on artificial intelligence (AI).”

Keeping pace with sustainable practices

As plastic bottling manufacturers keep stride with sustainable packaging trends, experts highlight some of the advancements in bottling technologies.

Sidel’s Boutroy points to the company’s innovative eco-solutions that support full packaging sustainability.

“The 1SKIN is a label-less bottle in PET that re-invents sensitive beverage packaging,” she says. “This innovative packaging combines distinctive shelf-appeal with the highest eco credentials as it is designed for recycling, made of 100% rPET and features an optimized weight. 1SKIN transforms PET bottles by removing the label, so marketing and mandatory information are available directly on the bottle surface, and a QR code is printed on the attached cap to extend consumers’ interactions.”

Additionally, Boutroy points to Sidel’s portfolio of services as the market transitions more to rPET.

“Earlier this year, Sidel showcased its rPET expertise by launching its RePETable offer — a unique portfolio of services designed to help the packaging industry make an efficient transition to rPET bottle production while offering support to improve the circularity of primary packaging,” she explains. “RePETable is designed to ensure manufacturers gain the benefits of utilizing rPET with no fear, achieving consistent production performance and bottle quality.”

Krones’ Igl points to how advanced equipment technologies work to support energy efficiency.

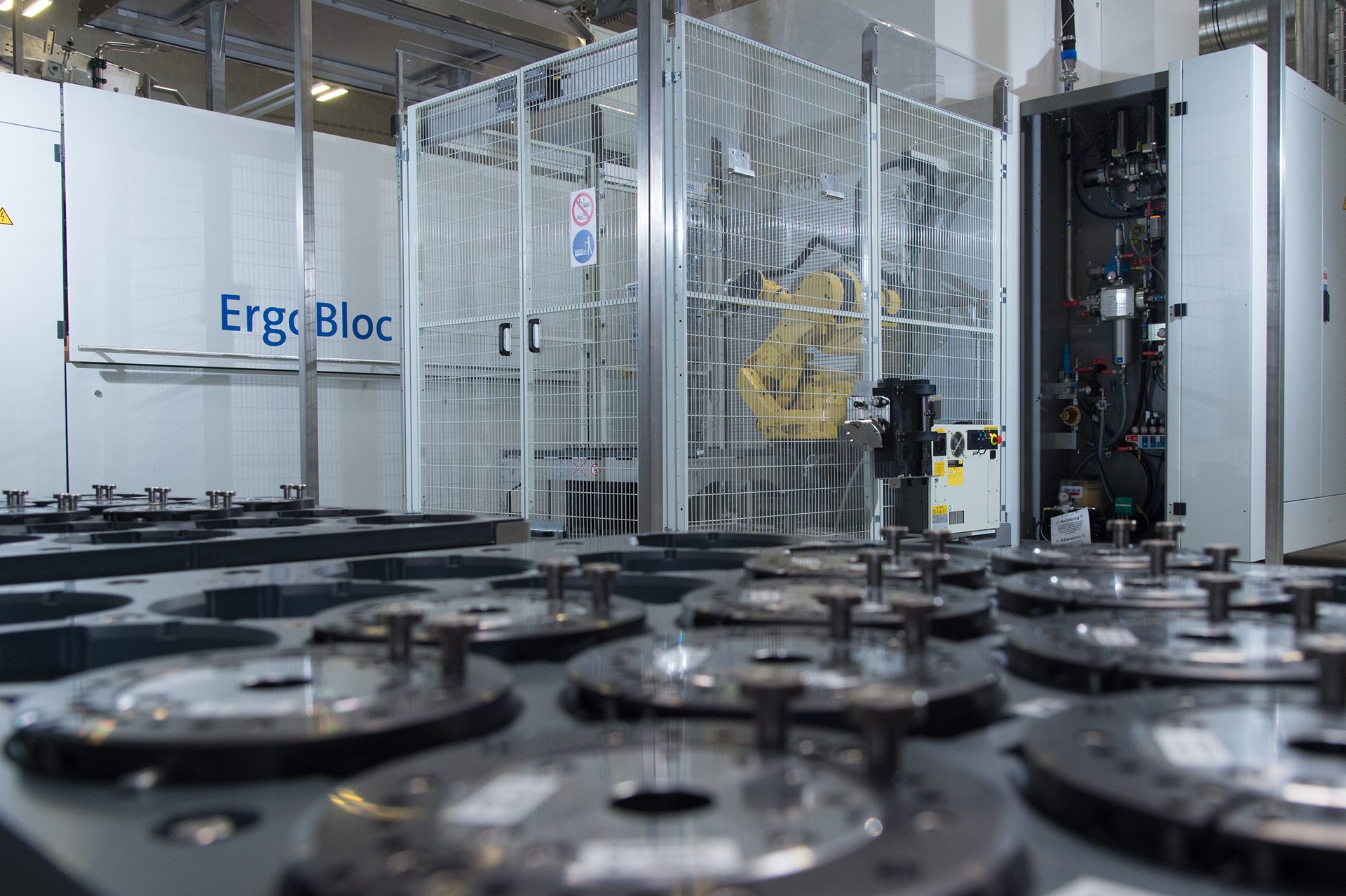

“Plastic bottle manufacturing equipment is getting more energy efficient. Our Contiform Generation 4 is the benchmark for the market,” he says. “It reaches higher outputs. Krones’ Ergobloc blowmolder has the fastest speeds currently in the market ― up to 100,000 bottles per hour ― and is getting more and more connected (embedded in the Krones digital Ecosystem).”

Krones offers solutions such as LineXpress for fast line changeover or flexible logistics solutions, Krones’ Peter Igl notes. (Image courtesy of Krones AG)

Investments for a sustainable future

For beverage manufacturers looking to invest in a plastic bottle manufacturing system, experts highlight some key factors to take into consideration.

“To address the worldwide trends toward sustainable packaging, beverage-makers should consider packaging manufacturing systems that help reduce their carbon footprint while also leveraging cost optimization,” Sidel’s Boutroy says. “So, securing production efficiency with lightweight packaging and 100% recycled content bottles is a key driver. Additionally, the production process should also fit with low energy and water consumption.”

Krone’s Igl points to investments in equipment to promote an operations overall cost efficiency.

“Trouble-free production with the lowest cost per bottle ― total cost of ownership (TCO) ― should be priority one and is what makes our customers’ operations highly successful,” he says.

Sidel’s Boutry adds that an optimized production set up — with combined blow molding, filling and capping in an integrated system — helps with production efficiency and line footprint.

“On top of this, packaging line digitalization is now a reality for key players in the industry as digital solutions enable greater agility, opening the doors to superior performance, faster time to market, lower operating costs and enhanced sustainability,” she concludes. BI