Warehouse

Optimizing today’s warehouse operations

Software solutions aid SKU proliferation, labor challenges

By Jessica Jacobsen

(Image courtesy of Blue Yonder)

In the episode of “The Missing Reel” of the Apple TV+ Emmy-winning series “The Studio,” Continental Studios head Matt Remick giddily talks about how much he enjoys watching the dailies on film and hearing the sounds that come with it. Only to have the film projector operator say how much he hates film because with digital all he has to do is hit a button.

Technological advancements have seen a variety of complicated processes become more streamlined. With the complexities of today’s beverage warehouses, software solutions are finding ways to make these operations more optimized.

“The ever-expanding capabilities of warehouse software are helping operations teams across the world better manage their fulfillment operations,” said Daniel Blessing, senior software consultant at Dematic, Grand Rapids, Mich. “Warehousing software is a helpful tool in inventory planning and fulfillment operations by leveraging analytics to pre-plan and optimize the work being performed by human staff and AGVs.

“This software can also help operation managers maximize their storage to accommodate more SKUs and streamline operations, which minimizes the human labor needed given increasing staffing challenges in the industry,” he continues. “Separate software applications can optimize operations as well, from transportation management systems that increase delivery route efficiency, labor management systems that enhance workforce tracking to optimize the workers in the building, and slotting solutions that reassign products to new locations to optimize pick paths in the building.”

Tom Gregorchik, vice president of industry strategy for grocery and CPG at Blue Yonder, Scottsdale, Ariz., explains that warehouse solutions can support both day-to-day and long-range optimization.

“There has always been a heavy emphasis on optimizing the day-to-day operations for receiving, intra-warehouse movements and shipping, while leveraging labor as efficiently as possible in terms of scheduling and attendance,” he says. “There is also an emphasis on long-term planning, both for labor and warehouse space. With shifting demand and constant robotics advancements improving efficiency, it’s important to plan longer term for capital-intensive assets of warehousing space, while balancing internal and external storage.”

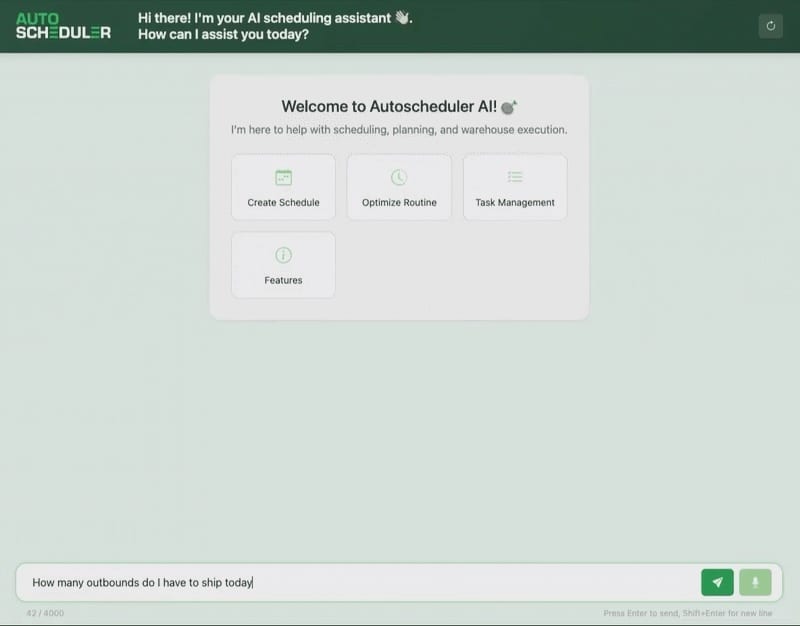

Warehouse decision agents can help connect the dots across labor, inventory and transportation, Keith Moore says.

(Image courtesy of AutoScheduler.AI)

Keith Moore, CEO at AutoScheduler.AI, Austin, Texas, meanwhile notes that although warehouse management systems (WMS) can serve as a digital backbone, the complexities of operations are prompting companies to seek intelligent tools to work alongside WMS.

“On the long-range side, companies use software to plan inventory positions, forecast demand by SKU, and slot products so tomorrow’s workload is easier to manage,” he says. “It’s about making sure new flavors, packaging changes, or promotions don’t overwhelm the floor. The real advantage comes when systems work together. A WMS maintains order, but Decision Agents, like AutoScheduler.AI, connect the dots across labor, inventory and transportation, so operations run smoother today and scale smarter for tomorrow.”

The benefits extend beyond efficiency as software solutions are delivering benefits to warehouse personnel.

“Warehouse software solutions make the warehouse a more efficient and effective work environment,” Moore says. “Instead of workers scrambling or chasing exceptions, systems prioritize tasks, so jobs are clear and achievable. Warehouse decision agents reduce wasted travel, balance workloads, and prevent bottlenecks, which lowers stress and fatigue. The result is safer, more predictable shifts where people can succeed and go home on time.”

Blue Yonder’s Gregorchik echoes similar sentiments.

“Warehouse software solutions ensure that warehouse personnel provide value-added work within the warehouse,” he says. “Oftentimes, there is disorder in a warehouse, and while everyone wants to do the right thing, they often don’t know exactly how to get there or work as a team. Warehouse solutions provide direct orchestration within the warehouse to help personnel add value to the operations rather than firefighting issues.”

Dematic’s Blessing also points to the physical benefits that warehouse software offers to personnel.

“Given the hefty and bulky nature of beverage products, warehouse software solutions can help take the load off human staff (both literally and figuratively) by optimizing workflows and reassigning more high injury-risk tasks to AGVs and other technologies,” he says. “For example, pick-to-voice systems allow operators to work hands free to pick large items and place them in the correct location. Additionally, enhanced safety aspects of mobile automation, such as the use of LiDAR on AGV and AMRs, also further reduce the risk of collisions in operations that use a mixture of manual and automated processes.”

“As customers continue switching products and pack sizes at the shelf to find value, maintaining efficiency in the warehouse is important for supporting accurate picking and shipping while optimizing labor to ensure On-Time In-Full (OTIF) performance.”

– Tom Gregorchik, vice president of industry strategy for grocery and CPG at Blue Yonder

Growing warehouse

Although it might be more commonly associated with store aisles, shifts in consumer preferences is shaping beverage distributors SKU lineup.

“Several trends are very prominent at the moment in the beverage market and are influencing the role software plays,” Dematic’s Blessing says. “As Gen Z grows into adulthood and becomes a larger share of the market, its tendency to prioritize healthier options and sustainable packaging are becoming key areas for companies to highlight in their marketing.

“This continues to increase the complexity of order fulfillment, as the volume of SKUs per order continues to increase and the environmental impacts may drive changes in packaging,” he continues. “Beverages going ‘healthier’ also means they contain more natural ingredients, less preservatives, or live cultures, meaning many more varieties must stay refrigerated. This translates to an increase in cold-chain warehouse storage solutions and temperature-sensitive monitoring.”

Blessing further notes that warehouse software has adapted to increase in breadth as well as functionality to support these expanded product portfolios.

“Software also offers options such as route management to optimize the load, remote temperature tracking to ensure cold-chain continuity, and delivery planning to decrease the number of trucks needed or the miles driven to fulfill a route,” he says.

As consumer preferences impact not just the types of products, but also the packaging, warehouse software solutions are helping beverage operations manage these growing portfolios.

“SKU proliferation is showcasing how important warehouse management systems are to consumer goods companies,” Blue Yonder’s Gregorchik says. “As customers continue switching products and pack sizes at the shelf to find value, maintaining efficiency in the warehouse is important for supporting accurate picking and shipping while optimizing labor to ensure On-Time In-Full (OTIF) performance.”

Further, Dematic’s Blessing notes that these expansive SKU portfolios are prompting the needs for advanced solutions.

“SKU proliferation is impacting warehouse software solutions by increasing the overall number of SKUs to manage, which highlights the need for advanced analytics tools,” he says. “More SKUs means more locations to pick from, more inventory to keep track of, and more labor needed to keep up with consumer demand.

“However, analytics tools can assist by leveraging AI and machine learning to review historical demand and current product mapping,” Blessing continues. “This technology helps determine the optimal amount of a product to carry at one time, allowing less lag time for ordering in-demand SKUs. In some cases, these solutions can even leverage AI assistants to make suggestions on changes to the warehouse that can further optimize their current system.”

AutoScheduler.AI’s Moore echoes similar sentiments.

“Traditional WMS platforms weren’t designed for the level of complexity that SKU proliferation has introduced,” Moore says. “They do a great job of recording inventory and enforcing process discipline. Still, they aren't built to constantly re-sequence work when you have hundreds of new SKUs, shifting promotions, and mixed-channel demand hitting the floor at once. A WMS is the backbone, but orchestration tools and decision agents, such as AutoScheduler.AI, provide the speed and flexibility to handle SKU proliferation without sacrificing service or margin.

“Warehouse Decision Agents sit on top of the WMS and constantly re-sequence labor, replenishment, and dock activity based on what's actually happening in the warehouse, not just what was planned yesterday,” he continues. “They ensure that companies can ship the right products at the right time and in the correct quantity to meet customer service level agreements.”

However, SKU proliferation is not the only market trend affecting beverage warehouses.

“Beverage distributors have various customer channels they need to address, including eCommerce, foodservice, mass market retailers and convenience stores, all coming out of the same facility,” Moore says. “This means there is more split-case picking, variety packs, and tighter service windows.

“Sustainability goals require beverage companies to reduce waste and cut emissions, which puts the focus on better slotting, fuller trucks, smarter trailer turns, and fewer touches to reduce dwell times and fuel usage,” he continues.

Moore also calls attention to the workforce, citing too few workers, high turnover rates, and rising costs.

“New hires require training as they lack experience,” he says. “As demand spikes, labor shortages create bottlenecks at docks, resulting in slower pick times and missed service windows. Warehouse Decision Agents like AutoScheduler.AI can address labor shortages by constantly resequencing tasks, such as picking, replenishment, and dock moves, in real-time. They ensure that people are always focused on the highest-impact work, keeping service levels on track despite fewer staff members on the floor.”

Blue Yonder’s Gregorchik further details how software solutions are helping to address labor challenges.

“Within the beverage market, there is still high pressure on labor costs and retention,” he says. “As a result, there is an increased emphasis on automating the warehouse as well as breaking down silos between customer service, logistics and deployment planning. In the past, warehouses operated based upon directions from other departments, but now, the labor costs among all execution areas are causing beverage companies to synchronize the warehouse with other areas of the business to reduce costs and improve service levels.”

An AI future

To help beverage warehouses address some of the biggest needs of the industry, experts anticipate that artificial intelligence will play a bigger role going forward.

“We can expect continued growth in warehouse software solutions’ AI capabilities,” Gregorchik says. “We are seeing more AI adoption helping answer questions about performance, critical issues and root cause analysis, and AI is delivering solutions to help solve problems. Warehouse operations continue to be complex, and AI allows for more visibility into how to improve day-to-day operations and minimize disruptions.”

AutoScheduler.AI’s Moore explains that warehouse decision agents, powered by AI, will help to connect between systems, including WMS, ERP and transportation systems.

“While a WMS sticks to the plan, decision agents react to what’s happening,” he says “When disruptions occur, managers often revert to using spreadsheets, making phone calls, or using radios to rebalance labor and adjust priorities. That gap between rigid execution and flexible problem-solving is where decision agents come into play.

“For example, a dock scheduling agent might see a surge in inbound trailers and reassign doors to avoid congestion,” Moore continues. “A labor agent could reshuffle shifts or call in overtime when order volumes spike. An inventory agent may redirect replenishment tasks to prevent stockouts on popular items. Together, these agents help transform a static plan into a living, breathing operation.”

Forecasting the impact of AI, Dematic’s Blessing also sees a growing impact from the supply chain on software solutions.

“As in many industries, the expansion of AI-driven products will continue to impact the beverage industry,” Blessing says. “We can expect to see the next step taken in the use of AI in the warehouse, shifting from AI assistants that only suggest changes to AI assistants that implement the change without needing approval from operators.

“As the supply chain becomes increasingly critical for many companies, we also expect to see the proliferation of solutions that span across multiple sites,” he continues. “This will allow for management of an entire network as opposed to siloed systems managing a single site without any connection to external locations. Multisite applications allow for easier aggregation of data across the network, leading to more informed decision-making and taking the entire system into account as opposed to making decisions in a vacuum.”

These advancements are sure to keep beverage warehouses optimized.