Supplier's

Marketplace

Wilmington’s Long Stroke Shuttle Blow Molding machines

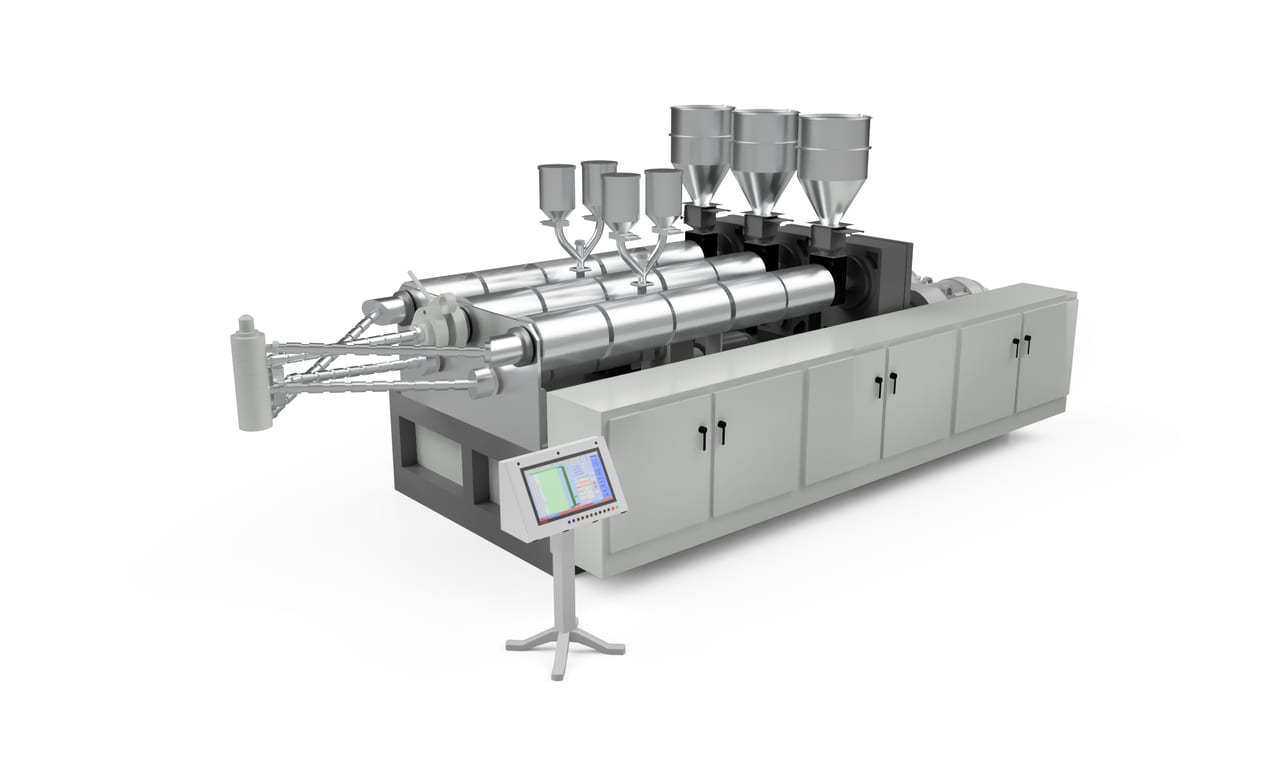

Wilmington Machinery continues development of its Long Stroke Shuttle Blow Molding machines to complement its current offering of high volume production Continuous Rotary Extrusion Blow Molding machines, which are used by the largest bottle makers worldwide, the company says. The new blow molding machines also will be sized for high volume applications of monolayer, three-layer, and barrier type handle ware, single-serve drink and chemical packaging. They will be capable of calibrated neck finishes, integrated deflash/trim and in-mold labeling of containers ranging in capacity from 6 ounces to 1.5 gallons. The company also has upgraded its Coextrusion Systems for rotary blow molding and other continuous extrusion blowing molding processes. The new systems are available for single or dual parision (programming) functions for all container sizes with one-, three- or six-layer construction. At the introduction of barrier bottle production more than 40 years ago, Wilmington now offers its systems to companies that have proprietary wheel or other types of blow molding machinery platforms. New to all Wilmington blow molding machinery products are the advanced control features. The new controls in addition to controlling the basic temperature, pressure and programming functions are significantly advanced in capability. Features include remote troubleshooting, statistical process control (SPC) charting, trend analysis, graphing and integrated auxiliary control — all on a large “smart” flat colored panel display.

Wilmington Machinery

4628 Northchase Parkway NE, Wilmington, N.C. 28405; 910/452-5090; www.wilmingtonmachinery.com.

Orbis Corp.

1055 Corporate Center Drive, Oconomowoc, Wis. 53066; 262/560-5000; www.orbiscorporation.com.

ORBIS’ Universal Container Pallet

ORBIS Corp. added a new Universal Container Pallet (UCP) to its suite of reusable plastic pallet offerings in Latin America. Designed to protect and transport foodservice products with ease, the 44-inch-by-56-inch two-piece snap-designed injection foam UCP optimizes daily operations in the food and beverage industry, the company says. The pallet’s plastic construction and flow-through rib design, which allows for easy cleaning and drying, makes the UCP a comprehensive solution for hygienic product distribution. The lightweight, durable and impact-resistant pallet features plastic construction, which makes it 100% recyclable at the end of its useful life. Additionally, the UCP is compatible with palletizers, depalletizers, automatic strapping/banding systems, conveyors and pallet washing systems, solidifying its place in ORBIS’ product lineup as a complete solution. The UCP also offers superior load stability and has central banding compatibilities with optional anti-slip grommets to help keep products secure. Highly impact resistant, the UCP’s 12-block design, thick deck ribbing and widened stringers all contribute to the pallet’s durability. The versatile pallet also can be optimized with divider sheets, top frames and stretch wrap to maximize product safety. Easily accessible, the pallet’s open base with chamfered base runners allows for improved full fork or low-profile hand truck access. It also can include advanced RFID or barcode configurations for added visibility into where products are located, preventing loss and increasing productivity. The new pallet will bring efficiency to food and beverage distribution throughout Latin America as the company grows its footprint in the LATAM region.

Regal Modsort Trident three-way sortation system

Regal Beloit Corp. showcased its new Modsort Trident three-way sortation system at Pack Expo. The Modsort Trident has a four-zone infeed that gaps a product, reads the package and sends it down a belt, where it then diverts left, right or straight on a 30-degree spur-curve to one of three sorting locations. A concept of Regal and a continuation of the company’s quiet Modsort technologies, the Modsort Trident is ideal as a secondary sortation station in a fulfillment center and works well with parcel post, eCommerce and warehouse distribution applications, the company says. The sortation system can accommodate as many as 50 cartons a minute on average, with a weight limit of 50 pounds. It utilizes a 34-inch-wide (between frame) by 66-inch-long triple-belt divert for polybags, boxes, flats and some types of totes. Designed to be mobile, the technology uses 24-volt DC power and requires only a simple power drop and Ethernet connection to a customer’s warehouse management solution. Other features of the Modsort Trident include frame mounted HMI operator control panel with pushbuttons for start/stop, reset, communications fault, and emergency stop; Allen-Bradley-based PLC controller/power panel and Allen-Bradley Stratix network switch; a compact Logix 5380 processor; and a digital/analog input/output backplane array.

Regal Beloit Corp.

200 State St., Beloit, Wis. 53511; 608/364-8800; www.regalbeloit.com.

TriMas Packaging

38505 Woodward Ave., Suite 200, Bloomfield Hills, Mich. 48304; 248/631-5450; www.trimascorp.com.

TriMas’ tethered cap solutions

TriMas Packaging expanded its caps portfolio with the acquisition of Affaba & Ferrari’s tethered cap solutions. Tethered caps — caps that remain firmly attached to the bottle after opening and during use — are designed to meet the new European Union (EU) 2024 directive to reduce the number of discarded plastic closures in nature. Tethered cap closures that are permanently attached to disposable beverage containers, including composite packaging such as beverage cartons with a volume of up to 3 liters, are easier to recycle, the company says. The aim is to recycle the caps together with the containers and prevent littering of the environment caused by discarded caps, marking another step in sustainability for the beverage industry. Noting that more directives like those being adopted by the EU are expected, the company will expand its products globally. Among its offerings are aseptic caps for juices, dairy products and sport isotonic/energy drinks, as well as tamper-evident, child-proof, flex-spout and caps and closures for use in the food and beverage industry. The tethered caps for aseptic beverages soon will be part of TriMas’s portfolio of closure solutions.

Emerson AVENTICS Series air preparation units

During Pack Expo, Emerson showcased the new integration of air preparation units for packaging equipment, the AVENTICS Series 652/652 with AVENTICS AF2 flow sensors. The combined solution enables more efficient air consumption and versatility for packaging lines. The integration of the air preparation units with the flow sensors provides a clearer picture of air consumption in pneumatic systems, while delivering valuable insights that can help facilities improve packaging line efficiency and overall equipment effectiveness (OEE), the company says. On their own, Series 652/653 air preparation units provide clean air and pressure control to downstream pneumatic devices; however, now that they can integrate with the AF2, end users can benefit from the versatility and wide variety of options this range of filters, regulators and lubricators (FRLs) offers. These FRLs are ideal for packaging, food and beverage, and process applications requiring highly reliable operation and robust, modern-looking equipment. Operators can monitor air consumption, including flow, pressure and temperature, to detect leaks and optimize energy use. With an integrated analysis option, the integrated solution provides alerts that enable the appropriate personnel to address early-stage leakage and perform preventative maintenance before issues arise. The integrated solution also can be retrofitted on existing machines with few changes and be directly interpreted by many different controllers.

Emerson

8000 W. Florissant Ave., P.O. Box 4100, St. Louis, Mo. 63136; 314/553-2000; www.emerson.com.

St. Louis-based HDA Architects announced that the design and construction of a new 114,295-square foot facility for Summit Beverage in Missoula, Mont., is complete. The new facility includes a 20,600-square-foot two-story office space that has a large training/meeting room, adjacent lounge/break room with an adjoining patio for hosting larger events, private offices, collaborative meeting space and three conference rooms. The second-floor conference room allows visible access to the warehouse, which is nearly 93,700 square feet. The concrete tilt-up controlled temperature warehouse includes a 11,700-square-foot space for draft kegs and beer cooler square, a large storage and loading area, space for vehicle maintenance and ancillary storage space.

Graphic Packaging Holding Co., Atlanta, welcomed Michelle Fitzpatrick as company's first chief sustainability officer (CSO). Fitzpatrick will support the company’s commitment to making a positive, lasting impact on the planet and on future generations through sustainable fiber-based consumer packaging solutions. As the CSO, she will collaborate with cross-functional global leaders at the company and will interact regularly with the Board of Directors, building on and executing the company's environmental, social and governance (ESG) strategy. Fitzpatrick holds a PhD in environmental (civil) engineering from the University of Massachusetts, Amherst, and a MSE in environmental engineering and BSE in chemical engineering from Tulane University.

INX International Ink Co., Schaumburg, Ill., announced that the company has expanded its educational profile for metal decorating customers through the creation of INX University, the quintessential ink industry eLearning resource. The market leader for metal inks and color management technologies, INX now is offering free remote courses in eight languages to help its customers and anyone involved in the design and production of metal packaging better understand the basics of inks, color managements and troubleshooting. In addition to English, courses are available in two Spanish language versions — Latin American (Español) and Castilian, which is spoken in Spain — as well as French, German, Italian, Polish and Portuguese.

The Business Intelligence Group has recognized PakTech for its Sustainability Product of the Year in the 2021 Sustainability Awards program. The Sustainability Awards honor those people, teams and organizations that have made sustainability an integral part of their business practices or overall mission. Throughout all aspects of development, the Eugene, Ore.-based, family owned company embraces a sustainable and circular approach by embracing the waste hierarchy, embodying the principles of reduce, reuse and recycle in its product designs. In addition to being 100% recyclable, PakTech’s handles reduce unnecessary plastic with their minimalist design and are durable, water resistant, comfortable to carry and easy to remove, the company says.

More than 90 volunteers from Bendix Commercial Vehicle Systems, Elyria, Ohio, worked in partnership with the nonprofit organization Sleep in Heavenly Peace (SHP) to build 31 beds for children in need. A $5,000 grant from Bendix covered the cost of all materials needed to build and furnish the beds, including mattresses and bedding. Additionally, Bendix organized a donation drive to collect funds and in-kind donations of bedding that could be included with the beds or gifted to future SHP recipients. On the morning of the event, additional Bendix volunteers and family members made 100 hand-tied fleece blankets for donation to the Cleveland Clinic Children’s Hospital and SHP recipients.

Universal Compressed Air (UCA), Bethlehem, Pa., welcomed Katherine Ricker as its controller. Reporting to Rick Kowey, senior vice president and chief operating officer, Ricker will lead UCA’s accounting, administrative and human resource functions. She has more than 15 years of experience in the accounting and finance industry, and holds a bachelor’s degree in accounting and finance from DeSales University. She currently is enrolled in their Master of Business Administration (MBA) program with a concentration in accounting.