Supplier’s Marketplace

FOX IV Technologies Inc.

6011 Enterprise Drive, Export, Penn. 15632; 877/436-2434; www.foxiv.com

Vacuum Interrupters

13765 Beta Road, Farmers Branch, Texas 75244; 214/442-5877; www.vacuuminterruptersinc.com

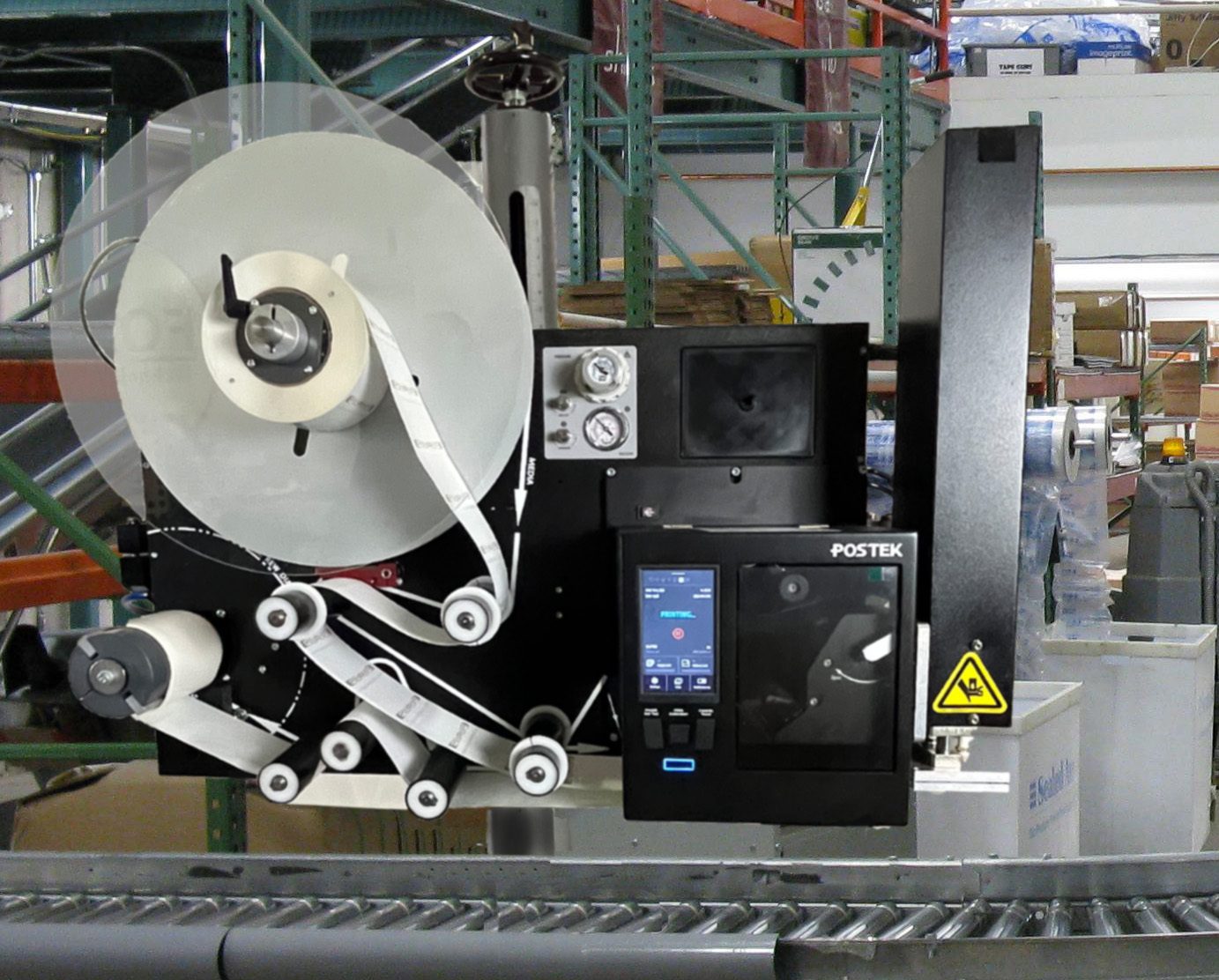

Entry-level label and print apply latest from FOX IV

At PACK EXPO International, which is set to take place Nov. 3-6 at Chicago’s McCormick Place, FOX IV Technologies will officially unveil its new 6312 Label Printer-Applicator. The 6312 is ideal for simple label print and apply applications, the company says, such as shipping labeling. It also works for small- to medium-size businesses looking to start their automation journey. The 6312 is designed to be an entry-level label print and apply solution and is “streamlined and simplified,” the company notes. By incorporating the Postek MX series print engine, FOX IV says that no external PC or PLC is required. “The 6312 is a great way to start automating your fulfillment process,” said Catherine Hornsby, marketing manager, in a statement. “The large, 4.5-inch touchscreen, built-in PLC and simplified applicator controls makes the 6312 easy for operators to use. It can be set up on a new or existing conveyor or used with a manual trigger for semi-automatic labeling.” The Postek MX print module is incorporated into FOX IV’s durable industrial applicator design. Labels up to 4.72 inches can be printed at speeds as fast as 18 inches per second (IPS), depending on model, and applied director to a product, shipping box, reusable tote or pallet. “Additionally, the entry-level price point makes automating labeling easier to justify by providing fast ROI through increased throughput, labor time savings and minimized labeling errors,” Hornsby added. “For companies ready to move to the next level, it’s a great starting point.” Several optional features are offered to customize the labeling experience, from RFID encoding and verification to barcode verification.”

Vacuum Interrupters introduces new replacement

Vacuum Interrupters, a manufacturer of replacement vacuum interrupters, pole assemblies, parts and components for medium-voltage circuit breakers and contactors, introduced the RVI-WL-35774D replacement vacuum interrupter. This replacement unit for the WL-35774D vacuum interrupters is a direct fit-and-function unit, meeting original equipment ratings. It is intended for use in Eaton SL and Cutler-Hammer SJ25V830 vacuum contactors. The RVI-WL-35774D is built to “provide excellent high-voltage insulation, high cumulative and breaking capacity, exclusive internal torsion control and an exceptional vacuum seal thanks to a fine alumina ceramic,” the company says. This replacement vacuum interrupter offers 800 A RMS-rated current, 7.2 kV RMS maximum voltage, 65 kV peak impulse withstand, as well as 12.5 kA RMS-rated short-circuit breaking current. Vacuum Interrupters notes that no modification is required for proper installation and operation in existing Eaton SL and Cutler-Hammer SJ25V830 vacuum contactors. The company also can provide assembly components and mounting hardware to aid in installation and shorten downtime.

Mallard Manufacturing

101 Mallard Road, Sterling, Ill. 61081; 844/340-7013; www.mallardmfg.com

Nokia Bell Labs

600-700 Mountain Ave., Murray Hill, N.J. 07974; 908/743-9230; www.nokia.com

Mallard Manufacturing unveils Slim-Fit carton flow divider

Gravity flow storage solution provider Mallard Manufacturing introduced a new Slim-Fit, full-length divider for wheeled carton flow systems. The product is custom-engineered and redefines efficiency and flexibility in carton and tote storage and picking applications, the company says. The dividers click into specially designed holders, which creates SKU slots of any width and maximizes shelf space for edge-to-edge storage. “We are thrilled to introduce the new Slim-Fit divider for our wheeled carton flow products,” said Kevin Risch, president of Mallard Manufacturing, in a statement. “This innovation reflects our commitment to addressing customer needs with advanced gravity flow solutions that enhance efficiency and help control operational costs.” The product’s thin profile allows for more SKU lanes, with adjustments in 0.17-inch increments to eliminate wasted space. It also features mirrored image divider brackets, speeding accurate slotting and reslotting, with secure fit double-action locking. The divider also comes in five color choices, with the option to mix and match. The Slim-Fit offers several key advantages, including enhanced SKU capacity to innovative bracket design, the company says. The product’s rounded-edge design and protective powder-coated finish prioritize worker safety by minimizing the risk of cuts and injuries, it notes. While they are durable, the dividers are lightweight, facilitating easy lifting and repositioning for swift reprofiling, it adds.

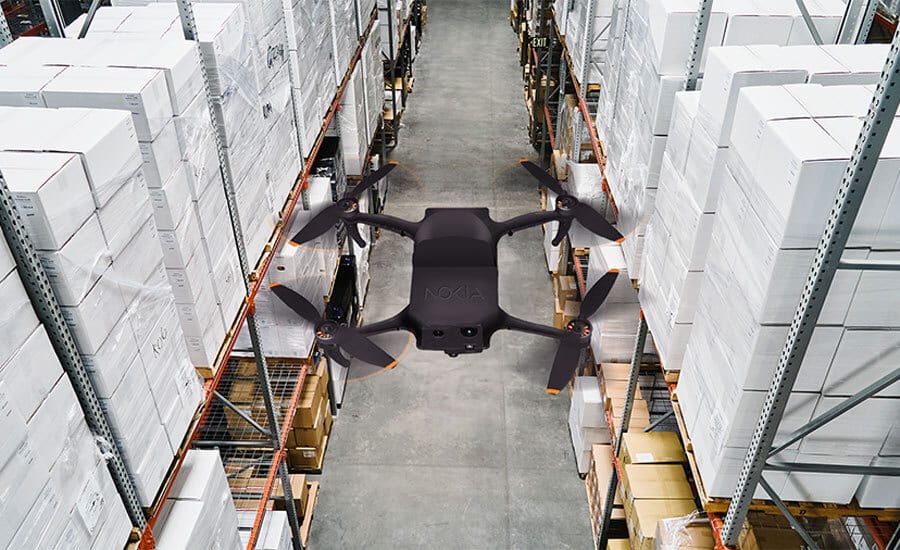

Nokia AIMS reveals automated inventory counting capability with drone service

Nokia recently launched a true inventory counting capability for Nokia Autonomous Inventory Monitory Service (AIMS). This new service enables warehouse operators to utilize autonomous drones to individually count items, from cases to cartons, in any racked inventory location and efficiency. The new inventory counting capability adds to Nokia AIMS’ current features of finding misplaced and lost inventory, as well as empty bin detection. If a human worker can count inventory from the aisle, the Nokia AIMS drone can, too. The drone’s identified inventory counts are then compared with the warehouse’s existing WMS or ERP systems to identify any quantity mismatches. Where typical cycle counts use the ABC method, where inventory is counted based on frequency, the Nokia AIMS efficiently checks every location much more frequently, ensuring customers get a more accurate, reliable and complete picture of their inventory, the company says. “Empowering warehouse operators with a competitive edge and keeping them at the forefront of automation is at the heart of what Nokia AIMS does,” said Paul Heitlinger, general manager of AIMS at Nokia, in a statement. “We are excited to launch an industry-first, true inventory counting capability for new and existing customers, wherever and whenever. With it, customers can not only gain peace of mind as our drones are designed to work while customers sleep, but also free up human workers for high-value tasks that make a difference for their businesses.”

Developer and operator of temperature-controlled distribution centers Vertical Cold Storage, sponsored by Platform Ventures, announced the grand opening of its Burleson, Texas facility. This is Vertical Cold Storage’s second distribution center in the Dallas-Fort Worth area. “Our Richardson facility is on the Dallas side of the DFW market and Burleson is on the Fort Worth side of the market, so now we can provide our customers with cooler, freezer, deep-freeze, blast freezing, case picking and a broad range of other temperature-controlled services from both sides of the market,” said West Hutchison, president and CEO of Vertical Cold Storage, in a statement.

Cimcorp recently announced it has supplied a new high-bay automated warehouse to longtime customer Olvi plc, a leading beverage producer in Finland and the Baltic region. More storage capacity in the automated warehouse supports Olvi’s growing production volumes and levels out seasonal demand of the brewing industry. “Our fruitful collaboration with Olvi spans nearly 20 years,” said Riku Puska, sales manager of warehouse and distribution at Cimcorp Group, in a statement. “Designing future development and innovating together have been the cornerstones of this partnership. Being available for our customers 24/7 and responding quickly to any requests are very important to us. In fact, delivering peace of mind is part of our DNA.”

Barry-Wehmiller declared a new role “that will bring transformative change to the organization.” Doug Neal was appointed to the role of vice president of continuous improvement, leading the efforts to reboot the organization’s dedication to operational excellence. “Barry-Wehmiller is a great organization with a great history and foundation,” Neal said in a statement. “I couldn’t be more excited about the opportunities here. Our focus will be on the people, ensuring they are involved and engaged in driving the changes needed to deliver results for our customers, stakeholders and team members.”

Global supplier of rigid packaging products Crown Holdings Inc. published its 2023 Sustainability Report, titled “A Shared Purpose.” The report details the company’s global sustainability progress, noting that it is on track to meet its Scope 3 emissions reduction goal ahead of the 2030 deadline. The goal falls under the Climate Action pillar of Crown’s Twentyby30 sustainability program, which was established in 2020 and includes 20 measurable sustainability goals to be completed by or before the end of 2030. “Our progress toward achieving our bold Twentyby30 goals is only possible with the commitment of our global team, and it is clear we have made strong strides together across our pillars of focus,” said Tim Donahue, president, CEO and chairman of the board of Crown, in a statement. “Our stakeholders rely on our transparency regarding sustainability performance, and it is up to us to remain advocates for strong standards and high performance sustainability.”

In an effort to establish a resource base and reinforce support for local distributors, INX International Ink Co. recently hired Blair Welch as the managing director for Australia and New Zealand. In this role, Welch will work with local distributors and develop new business in the Australia region, which also includes nearby islands in the South Pacific Ocean. “INX is a global leader in manufacturing inks and coatings for all printing processes, including digital inkjet,” Welch said in a statement. “This presented a unique opportunity for me to join a professional team that places a high priority on innovation and sustainability. With INX being the market leader in metal decorating, we have an excellent reputation for quality. This will provide instant credibility for entering other packaging segments in the region.”