Supplier's

Marketplace

Krones Autocol Inline PS Labeler

At the Craft Brewers Conference, Krones Inc. showcased its pressure sensitive small-footprint labeler for cans. The made-in-the-USA Inline Autocol Pressure Sensitive Labeler is designed to give craft brewers an edge with eye-catching labels to help their beer brands stand out from the competition. The labeler can handle multiple SKUs, small batches and limited runs and facilitate frequently changing artwork with a high accuracy labeling machine, it says. Additionally, the machine has a storage capacity of 10,000 cans. Key benefits include full wrap or partial labels; the ability to handle speeds of as many as 250 cans per minute (cpm); and the ability to accurately produce labels from one station with a maximum reel size of 400 millimeters. The Inline Autocol also provides the highest amount of flexibility in the smallest footprint for recipe changes, small batch limited runs and SKU proliferation. Using a combination of designed components from Krones and Kosme, the pressure sensitive labeler utilizes proven technology, features a single head design for quick and easy setups and a minimalistic table plate design, which allows many options for placement in the production line. With its compact design, operators are able to remain close to the production while staying safe behind the machine’s CAT 3 guarding.

Krones Inc.

9600 S. 58th St., Franklin, Wis. 53132; 414/409-4000; www.kronesusa.com.

Dorner

975 Cottonwood Ave., P.O. Box 20, Hartland, Wis. 53029: info@dorner.com; 800/397-8664; www.dornerconveyors.com.

Dorner FlexMove Helix Conveyor C

Dorner exhibited its packaging, automation and sanitary conveyors at Pack Expo 2021. The flexibility of its FlexMove Helix and Wedge conveyors were demonstrated as the equipment moved product on tight turns around existing equipment. The FlexMove flexible chain conveyor platform is designed for effective horizontal and vertical product movement on a continuous run driven by a single gearmotor when floor space is limited. As such, the conveyor provides facilities with greater flexibility in layout for applications such as accumulation, buffering, cooling product and more, the company says. The FlexMove Helix conveyor’s infeed and outfeed can be positioned at any height or angle. Meanwhile, custom infeed and outfeed lengths allow the conveyor to extend beyond the spiral, reducing the number of conveyors required. To support products that need to be held in place with more security while moving up and down steep inclines, the conveyor features its Helix Wedge. The Helix Wedge conveys product by gripping both of its sides to move it in a smooth, efficient manner. Helix conveyors feature continuous 360-degree turns for moving product up or down in a vertical space.

DW Reusables Bottlebee

An increasing demand for reusable packaging has driven the development of DW Reusables NV’s lastest innovation: Bottlebee. The reusable bottlebridge reduces water and carbon dioxide emissions from beverage six-packs and doubles the convenience of cardboard bottlebridges. Bottlebee works with full, sealed bottles as well as with empty bottles with no bottle cap. The innovation holds bottles tight below the top, unlike conventional carton versions that are held in place by the bottle cap, the company says. The cardboard is easily removed by tilting the bottle and taking it out. Additionally, the packaging is brandable for optimal product visibility at the point of sale and can be stacked two layers high. It’s also compatible with existing beverage crates as the Bottlebee is placed on the bottles in the crates and can be designed for any shape of bottle or crate. Supporting a circular economy, Bottlebee can be made from post-consumer material or regrind plastics and will last for years before being completely recycled into a new Bottlebee, according to the company. Furthermore, an independent study showed that Bottlebee with reusable glass bottles reduces carbon dioxide 64% compared with conventional packaging.

DW Reusables NV

Nijverheidsstraat 26, 3740 Bilzen Belgium; +011/0032-0-89-41-22-91; www.dwreusables.com.

Labeltronix

2419 E. Winston Road, Anaheim, Calif. 92806; 800/429-4321; www.dynamichybridlabels.com.

Labeltronix Dynamic Hybrid Labeling Solution

Labeltronix announced the release of the Dynamic Hybrid Labeling Solution. The new high-end solution combines premium craft labels with on-demand variable printing. The labeler prints premium customized labels as needed, without sacrificing label quality, it says. By offering a premium-printed base label, finished with a specialized coating, and an Epson printer for on-demand printing, brands can have the best of both worlds, the company says. The branded base label is printed flexographically and can be finished with embossing, spot varnish, hot stamping and more. When products are ready for labels, the brand prints the variable information on the branded labels using its on-site Epson printer. “We saw how many brands were struggling to balance quality, cost, and flexibility with traditional label printing,” said John Trail, president and partner at Labeltronix, in a statement. “The hybrid solution lets them use premium craft labels with the full flexibility of on-demand, on-site printing.” The Dynamic Hybrid Labeling is being used by many beverage brands, including wine, beer, spirits, cannabis products, nutraceuticals and more.

PS Safety Access EdgeSafe Safety Railing

PS Safety Access, the safety division of PS Industries, introduced the latest in its line of new, completely customizable safety and fall-protection products: the EdgeSafe Safety Railing. This combination of railing components is customizable and serves as the foundation for a complete safety system. The EdgeSafe Safety Railing protects workers from elevated edges, controls floor traffic or guards hazardous machines. By utilizing a universal, omnidirectional bracket, it is flexible enough to address almost any application and adaptable enough to follow virtually any required angle, the company says. The railing is sold in four components: 1-1/2-inch schedule 40 steel pipe as a horizontal railing (113 inches in length); vertical posts (3.5 inches each); and railing brackets that accommodate virtually any angle and/or an optional toeboard. Customers can purchase their own combination of these components to help increase safety from the top of the mezzanine to the ground level.

PS Safety Access

1150 S. 48th St. Grand Forks, N.D. 58201; 877/446-1519; www.pssafetyaccess.com.

Parsons-Eagle Packaging Systems

1415 Fortune Ave., De Pere, Wis. 54115; 920/983-7100; www.parsons-eagle.com.

Parsons-Eagle Phaser AB Vertical Form, Fill, Seal Machine

Parsons-Eagle Packaging Systems, a division of Campbell Wrapper Corp., displayed the Phaser AB Vertical Form, Fill, Seal Machine at the Pack Expo tradeshow. The filling and sealing machine is capable of producing pillow, gusseted or flat bottom packages from two inches to 13 inches in width and three inches to 15 inches in length at speeds in excess of 60 packages a minute. Features include an Allen-Bradley color touchscreen control, quick-thread film path, and an open architecture construction for ease of changeover and maintenance. The machine offers a number of machine options including a package support with eject, ultra-low profile frame design, fiber optic print registration, polyethylene film seal jaws, paper film seal jaws, hole punch, tear notch, flavor injection, pre-zippered re-closable package solutions and more. Phaser AB machines are ideal for short run, low- to medium-speed packaging of a wide range of products. At the tradeshow, the Phaser AB ran packages made from a new 100% certified recyclable all paper structure supplied by Paper People LLC that utilizes their patent-pending Paperlock heat sealing technology.

FlexXray, a leading inspection company for food and beverage manufacturers, will open a new state-of-the-art facility in Fort Mill, S.C. The expansion will create 100-120 jobs and bring state-of-the-art inspection services closer to the plethora of food and beverage producers in the southeast region for the first time, it says.

Hendrickson, Woodridge, Ill., announced that Gary Gerstenslager, president and CEO, will retire at the end of the year after 32 years with the global commercial transportation industry company. Gerstenslager joined Hendrickson in 1989, and his passion, technical knowledge, and drive for excellence led to a transformation in product design and manufacturing, which stands today, the company says. He will be succeeded by Matt Joy, who will be promoted as the fifth president and second CEO in Hendrickson's 105-year history, effective Jan. 1, 2022.

Manhattan Beer, New York, unveiled a new fleet of electric trucks at its Bronx, N.Y., location. The fleet will include five Volvo VNR Electric Class 8 trucks that will be charged using Tritium’s 75kw DC fast chargers and managed by AMPLY Power’s OMEGA charge management software. The software will ensure that the vehicles are being charged at times when energy costs are low while also guaranteeing that vehicles are fully charged and ready to roll out each day, it says.

Lancaster, Pa.-based Graham Packaging named Richa Desai as its new director of sustainability. In this role, Desai will support and drive company-wide sustainability initiatives including the development of goals, policies and programs that promote efficient, cost-effective products, technologies and operations. With a global background that includes work in European, Asian and U.S. markets, Desai has experience working on sustainability initiatives for a variety of professional brands in the manufacturing industry, most recently at Sabert, where she refined and championed the vision for Sabert’s sustainability platform and integrated sustainability into the packaging company’s business strategy.

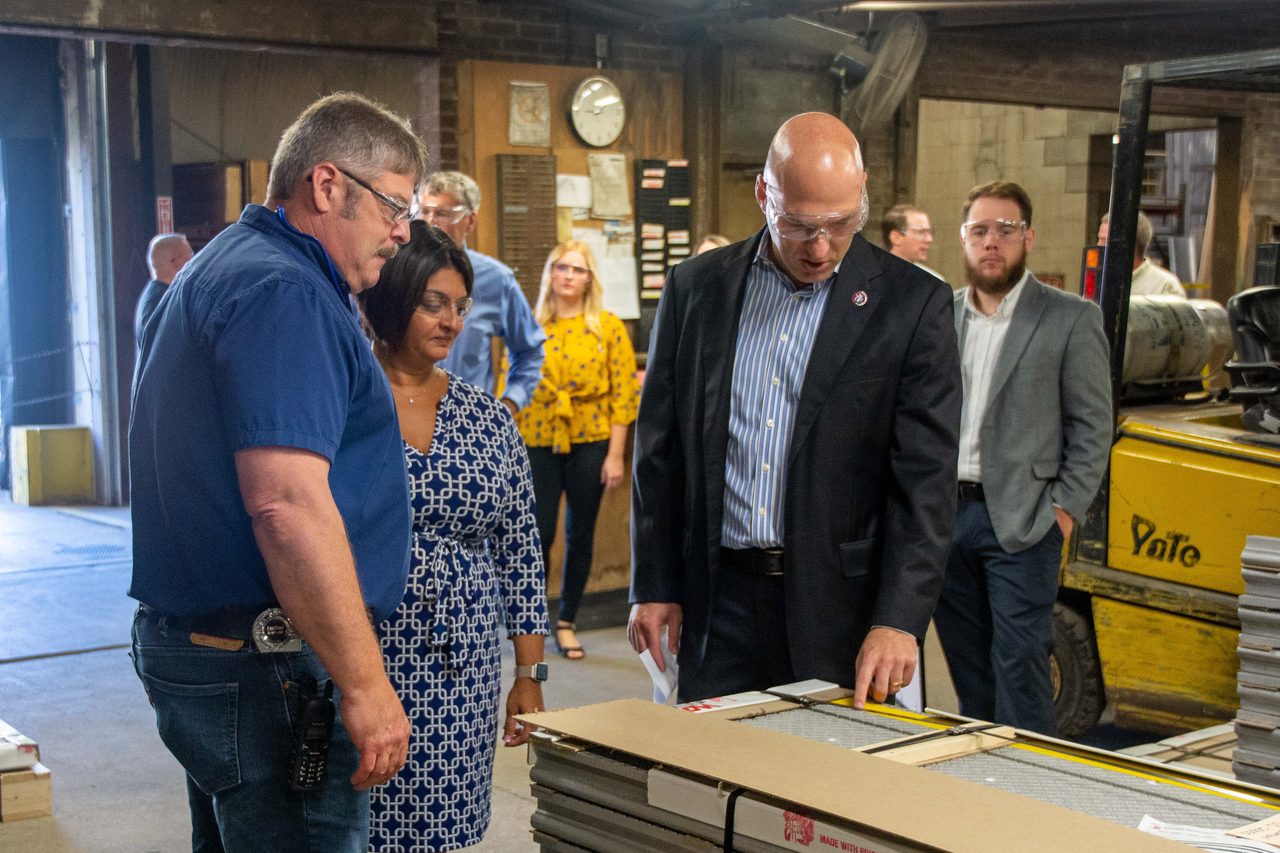

As part of its 100th anniversary celebration, Wooster Products, Wooster, Ohio, welcomed Congressman Anthony Gonzalez (R-OH), who presented a Certificate of Special Congressional Recognition honoring the company for its centennial celebration. “It's companies like this that built the country and employ our people,” Gonzalez said during the visit. The industry leader in anti-slip safety stair treads and walkway products has a slogan of “Make Every Step a Safe One.” The family run company employs many second and third generation employees, noted Wooster President Poonam Arora Harvey.

After 40 years of success building the smart factory, Elettric80, the Viano, Italy-based multinational, is consolidating and looking to the future as E80 Group. The automated intralogistics group was formed by the group’s founding partners, Enrico Grassi, president, and Vittorio Cavirani, vice president, who are 75% majority shareholders, and by holding company Ruck S.r.l., a minority shareholder, and integrated BEMA S.r.l., as its robotic division. With a broader development plan permeated by the team’s values to innovate, dare, solve, value and connect, the group will continue to promote innovation and sustainability as it grows in the market. Among its beverage clients are Danone, evian, Nestlé Perrier, The Coca-Cola Co., Constellation Brands and Niagara.

October 2021 | bevindustry.com