Operations

Meeting modern demand

HPP technology offers beverage brands a fresh take on minimal processing

By Lauren Sabetta

(Image courtesy of JBT Marel’s Avure HPP Science & Technology)

With work as a leading man that spans the comedy, drama and action film genres, actor, producer and former rapper Mark Wahlberg is quoted for saying, “I’ve always wanted to be in the health and wellness business. I try to encourage people to live a healthy lifestyle.”

Today, as healthy lifestyles often involve mindful eating and drinking, within the beverage industry health and wellness trends are giving rise to use of HPP technology, experts note.

“We’re seeing a strong demand for beverages that are fresh tasting, functional, and free from preservatives without sacrificing safety or shelf life,” says Roberto Peregrina, executive director at Hiperbaric High Pressure Technologies, Miami. “Cold pressed juices remain the category most closely associated with HPP, but the fastest growth is happening in functional drinks fortified with probiotics, adaptogens, plant proteins and other heat sensitive ingredients.”

Peregrina adds that consumers also are gravitating toward low sugar, clean label options, which align with HPP’s ability to deliver minimal processing while maintaining nutrient integrity.

“In parallel, sustainability trends are fueling interest in upcycled beverages made from surplus produce,” he says. “HPP makes these products safe while preserving their fresh flavor and color.”

Dr. Errol Raghubeer, senior vice president of JBT Marel’s Avure HPP Science & Technology, Chicago, echoes similar sentiments in terms of HPP technology having the ability to maintain a beverage’s functional integrity.

“Now more than ever, consumers are focusing on the health benefits and nutritional value of the products they buy, with juices, wellness shots and high-protein smoothie drinks continuing to rise in popularity,” he says. “With JBT Marel’s Avure HPP technology, these products can be fresher and safer for consumers. The high-pressure processing technology immerses products in a cold-water bath and applies even pressure, inactivating any food-borne pathogens and locking in nutrients, color and taste without added preservatives.”

As far as which beverage categories are most likely to take advantage of this technology, Raghubeer notes that cold-pressed fresh juices, wellness shots, fruit smoothies and other functional beverages are prime candidates for HPP.

“JBT Marel’s focus on ‘targeted nutrition’ directly applies to these types of nutritionally dense beverages, thanks to the technology’s ability to safely preserve these products without sacrificing any of the benefits, like antioxidant and anti-inflammatory bioactive compounds,” he explains.

Hiberaric’s Peregrina says that the application of HPP technology has brought about a significant transformation in the beverage manufacturing industry.

“There are several categories of beverages that can benefit from this technology, including cold-pressed juices and shots, smoothies, fruit-based waters like watermelon and coconut water, vegetable soups such as gazpacho, functional sport and energy drinks, non-dairy milks, as well as cold brew coffees and teas,” he says. “As the market trends toward functional beverages for their added supplements, vitamins and probiotics, this category is specially positioned to benefit from HPP as it extends shelf-life, while maintaining the flavor, color and heat-sensitive nutrients such as vitamins and enzymes.”

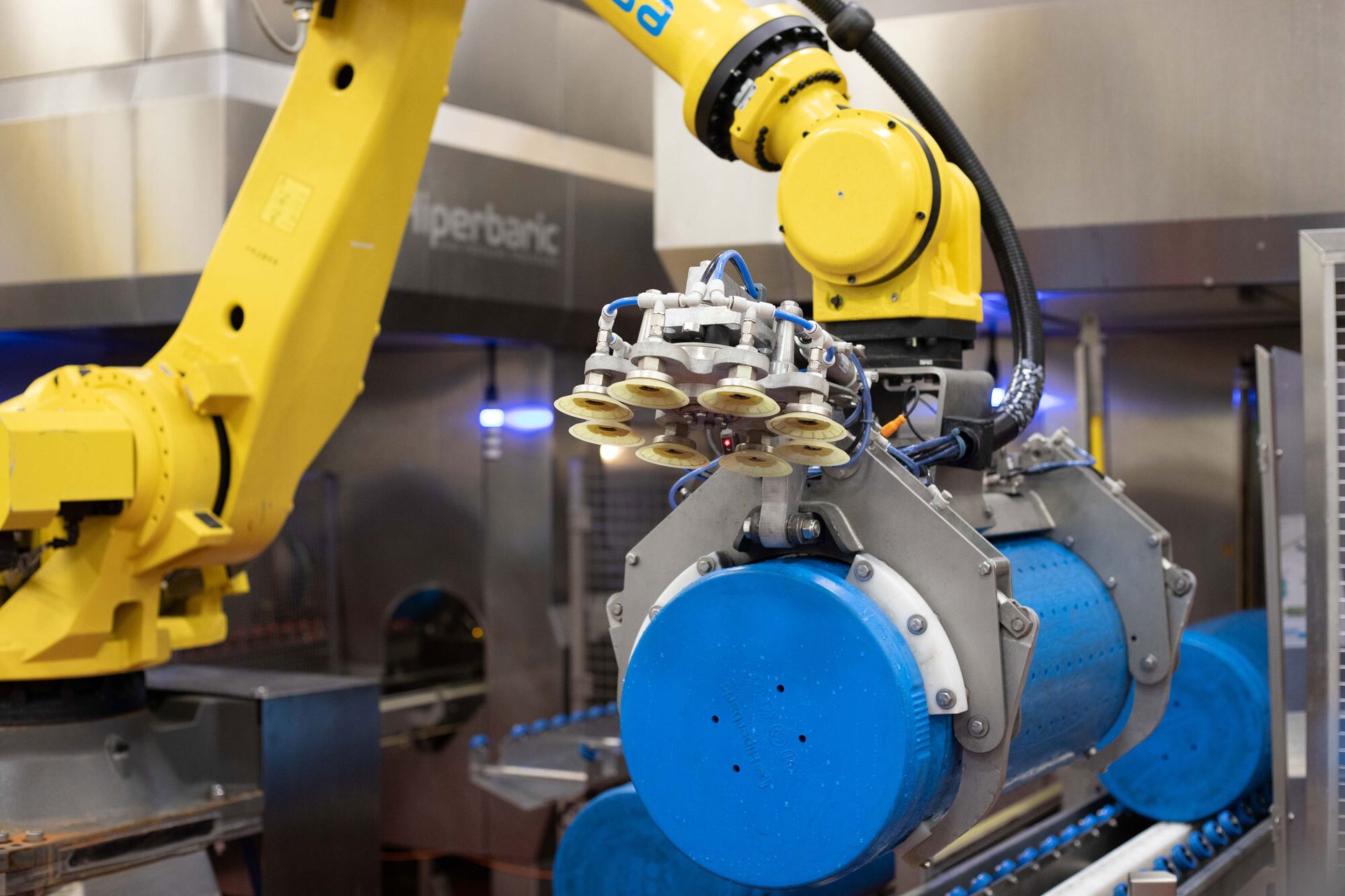

Hiperbaric systems can be integrated with robotic loading/unloading and pre feeder stations, improving throughput while reducing labor costs, Robert Peregrina notes.

(Image courtesy of Hiperbaric High Pressure Technologies)

The advantages

Coinciding with how HPP technology allows beverage brands to meet consumer demand for fresh, natural products with clean labels, experts highlight the benefits this technology can offer today’s manufacturers.

Hiperbaric’s Peregrina explains that because HPP is a post packaging, non-thermal process, it inactivates harmful pathogens without heat, preserving flavor, color and nutrients.

“This translates into a longer selling window, fewer returns, and reduced food waste,” he says. “For brands, it’s also a way to enter new retail channels and export markets that demand both food safety and extended shelf life without relying on preservatives or compromising quality. HPP is a competitive advantage.”

Keenan Drenning, director of HPP Americas at Quintus Technologies, Lewis Center, Ohio, notes that cold-pressed juices will begin to degrade within a few days without some method of preservation.

“HPP allows significant shelf-life extension without preservatives or heat,” he says. “It also takes place in the final bottle, which is great from a HACCP standpoint because it provides the critical kill step after all other processing has taken place. As long as the packaging and cold chain remain intact, there are few contamination risks after HPP.”

Avure’s Raghubeer also notes how HPP can extend the shelf life of fresh beverages and other high-pressure processed products.

“JBT Marel has found that there was no significant difference in the flavor of HPP-processed apple and orange juices after three months in storage compared to fresh juice after one week,” he explains. “Avure HPP processed beverages not only maintain just-squeezed taste and high nutritional value but are visually appetizing as well. An additional published study found that HPP-treated passion fruit puree retained better color quality and antioxidants compared to thermal processing.

“Customers can utilize our full food lab for product development alongside our industry-recognized food scientists who can provide Process Authority Letters for manufacturers,” Raghubeer continues. “Our food scientists can provide consultation on package design including cap/bottle interface and how to seal it to ensure success through the HPP process and extending shelf life.”

“Consumers tend to fall back on bottled waters for their perceived safety and better taste compared to tap water. Safety, health and convenience perks will drive continued growth of bottled waters.”

– Julia Mills, food and drink analyst at Mintel

“There are several categories of beverages that can benefit from this technology, including cold-pressed juices and shots, smoothies, fruit-based waters like watermelon and coconut water, vegetable soups such as gazpacho, functional sport and energy drinks, non-dairy milks, as well as cold brew coffees and teas.”

– Roberto Peregrina, executive director at Hiperbaric High Pressure Technologies

A vast frontier

With new advancements in HPP technology, experts note that beverage operations are able to improve throughput while reducing production costs.

Hiperbaric’s Peregrino explains that one of the major advances in high pressure processing is automation.

“Hiperbaric systems can be integrated with robotic loading/unloading and pre feeder stations, improving throughput while reducing labor costs,” he says. “We’ve also partnered with packaging innovators to expand dispensing options such as recyclable PET kegs that allow cold pressed juice to be served on tap in retail or foodservice settings.”

On the sustainability front, Peregrina adds that HPP is fully compatible with rPET bottles, enabling beverage brands to align with circular economy goals.

“And for processors looking ahead, our systems are Industry 4.0 ready, with remote monitoring, predictive maintenance, and data driven cycle optimization,” he says.

Avure’s Raghubeer explains that machine advancements not only reduce production costs but also time between production cycles.

“HPP technology has existed for decades, with Avure as a pioneer, releasing the first commercial high pressure processing system in 1950. JBT Marel’s Avure technology has undergone significant advancements from the AV-X, the world’s first expandable HPP machine, to newer models that save space, reduce production costs and increase throughput,” he explains. “In addition, new advances in pump skid technology increase throughput by reducing your time between cycles and reducing the required time to reach the desired pressure.”

Quintus’ Drenning also notes how machine advancements work to streamline beverage operations.

“Our presses are built with operational and maintenance ergonomics in mind,” he says. “Ample access to key components, simpler designs on routinely maintained components, and longer part lifespans are some of the design elements we’ve built into our next gen Quintus presses. We have also added real time monitoring and machine learning to predict when failures are upcoming so that the maintenance can be scheduled rather than reactive.”

As far as what is on the horizon for HPP and the beverage industry, Drenning says it is difficult to pinpoint what will drive more of the larger companies away from chemical preservatives and thermal pasteurization methods.

“HPP is sometimes viewed as an expensive technology, due to the upfront investment, but operating costs can actually be cheaper or comparable to the costs of chemical additives,” he explains. “Moreover, in some instances, thermal processing is damaging the naturally occurring compounds, like vitamin C, which then need to be added back into the product afterwards. HPP can maintain the nutrients of fresh ingredients, which is advantageous for the consumers and producers alike.”

Hiperbaric’s Peregrina foresees growth in three main areas, “Beyond juices, HPP will make inroads into low alcohol and non-alcoholic craft beverages, plant-based protein drinks, and shelf stable premium products through hybrid technologies like high pressure thermal processing (HPTP),” he says.

Additionally, Peregrina expects sustainability integration with increased adoption of rPET packaging and upcycled ingredient beverages.

“By incorporating rPET into your product mix, you can reduce your carbon footprint, decrease fossil fuel consumption, and contribute to the advancement of a circular economy, where all plastic is collected, reprocessed, and reused,” he explains. “The circular economy is the ultimate vision for long-term sustainability, and with rPET, we can help make this a reality while preserving recyclability and adding value to recycled PET.”

Lastly, Peregrina anticipates expanded accessibility with more HPP tolling centers and co-packing facilities that will make it easier for emerging beverage brands to launch without heavy capital investment, accelerating innovation across the sector.

Avure’s Raghubeer adds that high-pressure processing reduces the need for additives and results in pure, nutrient-dense products with antioxidants and anti-inflammatory properties.

Moreover, HPP also is compatible with several types of packaging including recyclable and reusable plastics, helping to satisfy sustainability concerns, he notes.

“HPP technology opens up a world of opportunity for the beverage industry as consumers’ health consciousness continues to rise,” Raghubeer concludes.